أخبار رائعة! لقد قمنا بشحن مجموعة كاملة من خطوط إنتاج شرائح الموز الأوتوماتيكية بالكامل إلى عميل لمعالجة الأغذية في تايلاند. هذا العميل يعمل منذ فترة طويلة في المعالجة العميقة للفواكه والخضروات بالإضافة إلى إنتاج الوجبات الخفيفة، وتتمتع علاماته التجارية باعتراف كبير في السوق المحلية.

مع تزايد الطلب من المستهلكين على الوجبات الخفيفة الصحية، يخطط العميل لتوسيع خط منتجات الموز الخاص بهم من خلال تقديم شرائح الموز المقرمشة ذات النكهات الفريدة لتعزيز القدرة التنافسية في السوق.

تكوين خط الإنتاج والمزايا

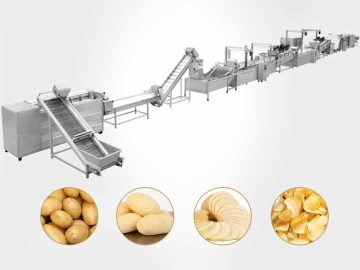

يشمل خط إنتاج شرائح الموز المشحون المعدات الأساسية مثل قشّارات الموز، وأجهزة التقطيع، وأجهزة القلي، وأجهزة التجفيف الهوائي، وآلات تغطية السكر، ومصارف الزيت، وآلات التتبيل، وآلات التعبئة.

يستخدم الخط بأكمله نظام تحكم ذكي لتحقيق إنتاج مستمر وآلي مع عملية بسيطة، وكفاءة في استهلاك الطاقة، وإنتاجية عالية.

صنعت من الفولاذ المقاوم للصدأ من الدرجة الغذائية، وتلتزم المعدات بمعايير النظافة الدولية. تظهر شرائح الموز النهائية لونًا ذهبيًا، وملمسًا مقرمشًا، وجودة متسقة، مما يجعلها مثالية للإنتاج على نطاق واسع.

موقع شحن خط إنتاج شرائح الموز

في يوم الشحن، قام فريق فحص الجودة لدينا بإجراء اختبار شامل وتصحيح للأداء لضمان استقرار الأداء ودقة المعايير.

بعد ذلك، قام الموظفون بتحميل الآلات إلى الحاويات على دفعات، باستخدام صناديق خشبية محترفة وتدابير تثبيت مقاومة للاهتزاز لضمان النقل الآمن خلال الشحن البحري لمسافات طويلة.

عبّر العميل عن توقع قوي لبدء تشغيل المعدات فور وصولها، متوقعًا استخدامها في مشروع معالجة عميقة داخل منطقة زراعة الموز المحلية.

سيعمل إدخالخط إنتاج شرائح الموز الأوتوماتيكي بالكاملعلى تعزيز كفاءة الإنتاج وجودة المنتج بشكل كبير، مما يحقق فوائد اقتصادية أكبر وتأثيرًا أكبر للعلامة التجارية لمؤسسة العميل.