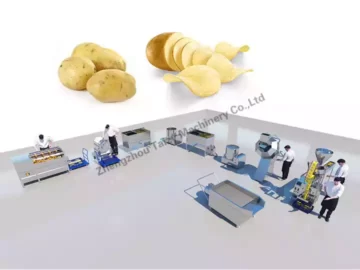

Na indústria de processamento alimentar moderna, o processo de embalagem desempenha um papel crucial na vida útil do produto e nas vendas. As máquinas de envase a vácuo não apenas proporcionam embalagem eficiente para batatas fritas congeladas, mas também são amplamente utilizadas para as necessidades de armazenamento e venda de vários alimentos, como arroz, farinha e secos.

Conservar a frescura e prolongar a vida útil

As máquinas de envase a vácuo removem o ar dos sacos de embalagem, minimizando os riscos de oxidação, humidade e crescimento bacteriano.

- Para as batatas fritas congeladas, a embalagem a vácuo ajuda a manter a cor e a textura do produto.

- Para grãos como arroz e farinha, evita eficazmente a infestação de insetos e a humidade, prolongando o tempo de armazenamento e oferecendo uma garantia de qualidade mais fiável para as vendas.

Aumentar a eficiência e reduzir os custos de mão de obra

Em comparação com a embalagem manual tradicional, as máquinas de embalagem a vácuo são fáceis de operar, mais rápidas e conseguem realizar operações de embalagem a granel e padronizadas.

Quer seja uma fábrica de processamento de alimentos, empresa de alimentos congelados ou indústria de processamento de grãos, este equipamento pode ajudar a melhorar a eficiência de produção, reduzir os custos de mão de obra e tornar o processo de embalagem mais estável e eficiente.

Máquina de selagem a vácuo versátil

Com a sua aplicabilidade flexível e desempenho estável, esta máquina de embalagem a vácuo não só satisfaz as exigências do mercado interno como também cumpre as normas de exportação de alimentos.

Quer se trate de alimentos congelados, ingredientes alimentares básicos ou especiarias secas, as empresas podem obter um prazo de validade mais longo e um maior alcance de vendas através da embalagem a vácuo.

Conclusão

A máquina de embalagem a vácuo multifuncional, com as suas características de “multifuncional, preservação eficiente”, melhora significativamente a utilização do equipamento e ajuda as empresas a reduzir o investimento em equipamento.

Não só ajuda as empresas a poupar custos, como também aumenta a competitividade do produto. Se procura uma máquina de embalagem que equilibre eficiência com requisitos diversificados, esta máquina de embalagem a vácuo é sem dúvida a escolha ideal.