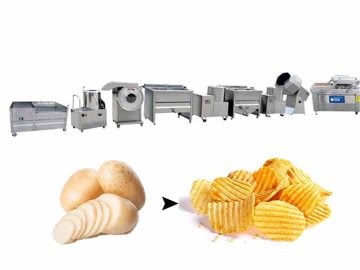

Bisnis pengolahan keripik kentang selalu menjadi pilihan umum bagi banyak investor di industri makanan. Perkembangan bisnis pengolahan keripik kentang tidak hanya memiliki pengembalian cepat, tetapi juga operasi yang sederhana, sangat cocok untuk pengolah kecil dan menengah untuk berinvestasi. Baru-baru ini, pabrik kami mengekspor garis pengolahan keripik kentang semi-otomatis dengan kapasitas 200kg/jam ke Rusia.

mesin penggoreng keripik kentang

mesin penghilang minyak

Mesin perasa keripik kentang

200kg/jam Garis pengolahan keripik kentang konfigurasi untuk Rusia

| Item | Pparameter |

| Pengupas Kentang | Kapasitas: 700kg/jam Daya:1.1kw Kapasitas: 700kg/jam ukuran: 1580*850*800mm Berat:180kg Bahan: semua 304 Stainless steel |

| Pemotong kentang | Model: TZ-600 Ukuran:750*520*900mm Kapasitas: 600kg/jam Berat: 70kg Daya: 0.75KW Bahan: semua 304 Stainless steel Pisau: keripik 2mm Termasuk 3 pemotong tambahan (3 set lengkap pisau pada disk untuk keripik 1.5mm/ kentang goreng 4mm/ keripik gelombang 2mm) |

| Mesin de-water | Model:TZ-800 Ukuran: 1400*940*800mm Kapasitas:700kg/jam Berat: 480kgDaya: 3kw Bahan: stainless steel 304 |

| Mesin penggorengan | Model: TZ-3500 Ukuran: 3500*1010*1550mm Kapasitas: 500kg/jam Berat: 910kg Daya: 70kw Bahan: stainless steel 304 Tangki minyak: 900L Termasuk pompa, tangki, dan semua tabung penghubung untuk menghubungkan penggorengan, tangki minyak, pompa, dan filter minyak. |

| Vibrasi mesin de-minyak | Model: TZ-2000 Ukuran: 2000*1320*1200mm Kapasitas: 500kg/jam Berat: 260kg Daya: 0.36kw Bahan: semua 304 Stainless steel |

| Mesin tiup udara | Model: TZ-3000 Ukuran: 3000*1350*1850mm Kapasitas: 500kg/jam Berat: 420kg Daya: 3.32kw Bahan: semua 304 Stainless steel |

| Mesin bumbu | Model: TZ–2400 Ukuran: 5000*1000*2100mm Kapasitas: 1000kg/jam Berat: 500kg Daya: 0.75kw Bahan: semua baja tahan karat 304 Termasuk perangkat dispensing dan conveyor |

| Tangki penyimpanan minyak | Model: TZ-800 Ukuran: 1120*1230*750mm Ukuran tangki: 845*845mm Daya: 3kw Bahan: semua baja tahan karat 304 Termasuk 30 kertas filter dan 1 kotak bubuk filter |

| Mesin pengemas | Model: TZ-720 Panjang kantong: 100-400mm(L) Lebar kantong: 180-350mm(w) Ukuran pembentuk: lebar 30cm, panjang 40cm Lebar maksimum film gulung: 720mm Kecepatan pengemasan: 5-50 kantong/menit Rentang pengukuran: 6000ml(Maks) Konsumsi udara: 0.65Mpa Konsumsi gas: 0.4m³/menit Tegangan: 220VAC/50HZ Daya: 5.5Kw Berat: 1260kg Termasuk conveyor, printer, perangkat nitrogen, perangkat punch, set pembentuk tambahan (lebar kantong 18cm, panjang 21-23cm) |

Bagaimana cara mengemas keripik kentang renyah di Rusia?

Konsumen utama dari Rusia ingin menggunakan garis pengolahan keripik kentang untuk memproduksi keripik kentang bergelombang, yang kemudian dikemas dan dijual ke berbagai toko kelontong dan supermarket lokal.

Untuk mencegah keripik kentang renyah pecah dan mempengaruhi penjualan, kami merekomendasikan mesin pengemasan keripik kentang dengan fungsi pengisian nitrogen untuk pelanggan Rusia ini.

Mesin pengemasan otomatis dapat mengisi kantong pengemasan keripik kentang dengan sejumlah nitrogen sehingga kantong dalam keadaan mengembang, dan keripik kentang tidak rusak karena tekanan. Gaya kantong pengemasan keripik kentang dipilih oleh pelanggan.

Mesin pengemasan keripik kentang renyah

Pengemasan keripik kentang