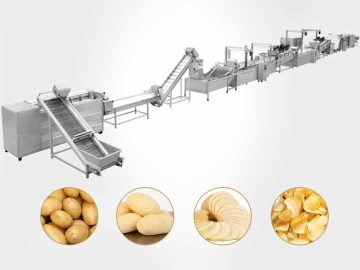

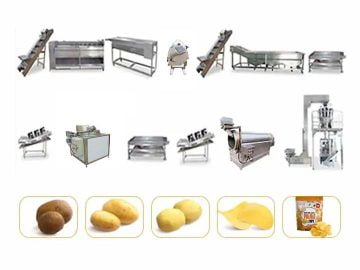

Na moderna indústria de batatas fritas congeladas e alimentos pré-processados, as máquinas automáticas de corte de batatas revolucionaram o processamento de alimentos com uma precisão de corte de ±0,5 mm, fatiando batatas cruas em batatas fritas uniformes (4 x 4 mm a 10 x 10 mm) ou fatias grossas a velocidades de até 10 toneladas por hora.

Corte perfeito de precisão

- A máquina utiliza lâminas de liga de alta dureza (HRC 58-62) que giram a 1.500-4.500 RPM para garantir 98% de suavidade e integridade da superfície.

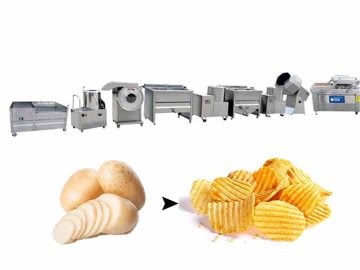

- O sistema de lâminas modular alterna entre batatas fritas, chips ondulados ou fatias em menos de 3 minutos para atender às necessidades de diferentes linhas de produtos sem tempo de inatividade.

Eficiência de grau industrial

- De 100 kg/h em pequenas cozinhas a 10 toneladas/h em grandes fábricas, esses cortadores aumentam a produção enquanto reduzem os custos de mão de obra.

- Por exemplo, o modelo ZYPC400 pode processar 300-400 kg/h com apenas 1,5 kW de potência.

- O módulo de alimentação inteligente organiza automaticamente as batatas (30-150 mm de diâmetro) e regula a velocidade do transportador (0,5-1,2 m/s), reduzindo o desperdício para menos de 3%.

- Compatíveis com linhas de descascamento, branqueamento e congelamento, essas máquinas suportam a produção de batatas fritas congeladas e vegetais preparados de ponta a ponta.

Máquina de cortar batatas automática e durável

Construído em aço inoxidável 304 de grau alimentar (1,5-2 mm de espessura), o cortador é resistente à corrosão e abrasão, bem como resistente a alta umidade, tornando-o ideal para instalações frequentemente lavadas. As principais melhorias incluem:

- Habitação totalmente fechada para prevenir contaminação.

- Cintas e lâminas abrasivas substituíveis para vida útil prolongada.

- Design de baixa manutenção: o sistema de transmissão por correia garante operação suave e manutenção mínima.

Versátil: expandindo a inovação alimentar

Otimizado para batatas, estas máquinas automáticas de corte de batatas também podem lidar com cenouras, batatas-doces, taro e mais. Sua adaptabilidade suporta:

- Linhas de vegetais preparados: para produzir vegetais fatiados/estriados uniformemente para saladas, sopas e pacotes de lanche.

- Padrões globais de exportação: Atenda aos padrões da UE para batata frita tamanhos para atender às demandas do mercado internacional.

- Flexibilidade para restaurantes e retalho: desde cadeias de fast food até pequenos cafés, os volumes de produção podem ser aumentados para atender à demanda sem comprometer a qualidade.

Quer aumentar sua linha de produção de batatas fritas? Entre em contato conosco hoje para solicitar um orçamento, visualizar um vídeo de demonstração ou discutir detalhes de personalização.