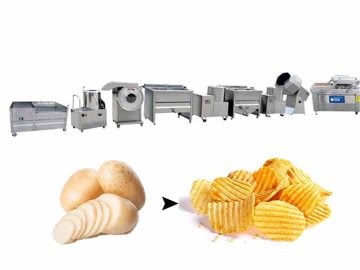

Com o rápido crescimento dos mercados de alimentos saudáveis e processamento doméstico, as máquinas de fatiar batatas tornaram-se equipamentos indispensáveis na produção de chips de batata e batatas fritas. Comparado ao fatiamento manual tradicional, este equipamento mecanizado não só aumenta a eficiência, mas também garante uma espessura de fatia uniforme, impactando diretamente a textura e a qualidade visual do produto final.

- Fatiadores de batatas domésticos modernos geralmente processam de 100 a 500 kg de batatas por hora, atendendo de forma suficiente às demandas diárias de cozinhas domésticas, pequenos ateliers de alimentos e empreendimentos.

- O equipamento apresenta uma estrutura compacta com uma pegada pequena, permitindo uma colocação fácil nas áreas de produção. Este design economiza espaço enquanto facilita a mobilidade e operação.

- Para utilizadores que necessitam de processamento contínuo, uma capacidade de produção estável reduz significativamente o esforço manual e aumenta a eficiência geral do processamento.

Design de fatiamento de precisão garante a qualidade do produto

A qualidade do fatiamento determina diretamente os padrões finais de chips de batata e batatas fritas.

- A máquina de fatiar batatas emprega um disco de lâmina de aço inoxidável de alta resistência e um sistema de alimentação automática, permitindo que as batatas sejam fatiadas rápida e uniformemente assim que entram no percurso de corte.

- Ajuste de espessura geralmente varia de 1 a 6 mm, configurável livremente para atender a diferentes requisitos de produto, tornando-se adequado para processar chips finos, chips ondulados, batatas fritas grossas e mais.

- A espessura uniforme das fatias garante um aquecimento consistente durante a fritura ou secagem, minimizando quebras e desperdício de borda.

Dados indicam que equipamentos de fatiamento automatizado aumentam as taxas de passagem do produto final para mais de 95%, além de aumentar a utilização de matéria-prima em aproximadamente 10–15%. Isto impacta significativamente o controle de custos de produção e a apresentação do produto.

Máquinas de fatiar batatas reduzem custos operacionais

- A fatiadora de batatas doméstica é construída inteiramente em aço inoxidável de grau alimentício 304, oferecendo resistência à corrosão e fácil limpeza para manter altos padrões de higiene mesmo durante operações prolongadas.

- Equipado com um painel de controlo automático, o dispositivo realiza alimentação, fatiamento e descarte com um único pressionar de botão, permitindo que operadores não especializados gerenciem tarefas de produção de forma independente.

- A manutenção é simplificada com remoção e substituição rápidas da lâmina, exigindo apenas uma limpeza diária simples para prolongar a vida útil.

- Em comparação com o fatiamento manual, o equipamento mecânico economiza mais de 70% em tempo e custos de mão-de-obra, tornando-o ideal para necessidades de processamento de alimentos estáveis e de longo prazo.

- Para empreendedores domésticos ou pequenas fábricas de alimentos, isto representa um investimento ideal: baixo custo, retorno rápido e operação simples.

No geral, a máquina de fatiar batatas doméstica oferece garantia confiável para a produção de chips de batata e batatas fritas através de sua eficiência, precisão e facilidade de manutenção. É uma escolha crucial para melhorar a qualidade e produtividade do processamento de alimentos.