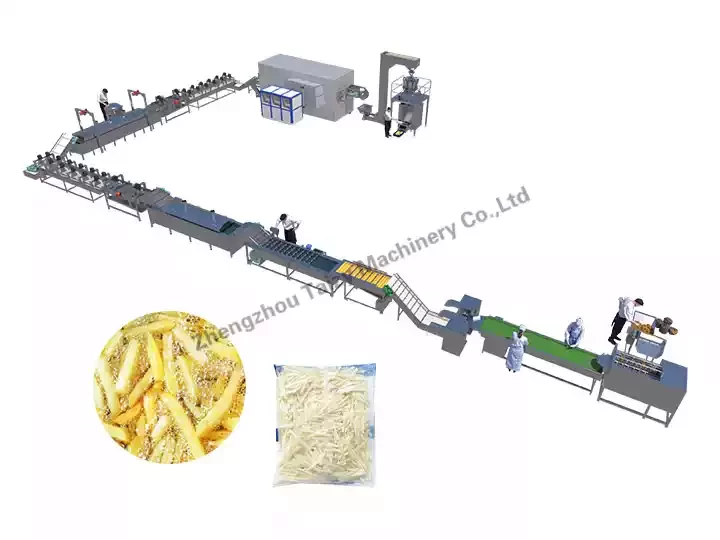

Detailed parameters of the whole frozen French fries production line

froz en French fries production lineparameters

| Kitu | capacity |

| 1000 kg/h | blanching temperature |

| 95 degree | blanching time |

| 30 s | de-water/de-oil time |

| 2 min | frying temperature |

| 160-180 degree (the temperature can be adjusted) | frying time : 40-60s |

| 40-60s(for frozen french fries) | power consumption/day |

| about 483kw(When the machine runs smoothly, it only needs half the power.) | oil consumption/day |

| 5%(the first time fryer machine need to put 2T) | water consumption/day |

| 500–600kg | working area |

| about 1000 ㎡ | workers number |

| 6-10stuffs | machine material |

| 304 stainless steel | transportation |

| need 6 *40HQ Containers | specification |

Spare parts of 1000kg/h french fries production line

| Hapana | Kitu | sorting machine |

| 1 |  Machine size : 5500*1800*1200mm | Weight : 2200kg Capacity : 1000kg/h Voltage : 380v 50hz Remarks : 304 stainless steel; 3-5levels according to customers’ demands; with hoist Nguvu: 1.5kw Silo |

| 2 |  Size: 2000*1330*1200mm | Power: 1.1Kw Capacity: 2t/h Remarks: 304 stainless steel. Power: 0.55 kW |

| 3 |  Kuinua | Voltage: 380 v 50 Hz Size: 1800*800*1500 mm Functions: The raw potatoes are removed by this hoist into the pre-washing machine. Remarks: The electric appliance used is the Schneider brand, the inverter is Mitsubishi of Japan, and the motor speed is adjustable; PVC and 304 stainless steel. Pre-washing machine |

| 4 |  Power: 4.37kw | Voltage: 380 v/50 Hz Size: 3400*900*1400 mm After the potatoes are lifted, they enter the pre-washing machine, and the dirt on the surface of the potatoes is cleaned by rolling and spraying, and then the next step is performed. Remarks: 9pcs hair rollers; with a circulating filtering water tank at the bottom; automatically discharged by screw driving; the peeling time and speed can be adjusted; the inverter is the Japanese Mitsubishi inverter, and the electrical appliances are brand Schneider. Washing machine |

| 5 |  Power: 4.37 kW | Function: The pre-washed potatoes enter the peeling machine through a hoist, and are thoroughly peeled through a soft roller and water spray. Size: 3400*900*1400 mm After the potatoes are lifted, they enter the pre-washing machine, and the dirt on the surface of the potatoes is cleaned by rolling and spraying, and then the next step is performed. Remarks: 9pcs hair rollers; with a circulating filtering water tank at the bottom; automatically discharged by screw driving; the peeling time and speed can be adjusted; the inverter is the Japanese Mitsubishi inverter, the electrical appliances are brand Schneider. Picking table |

| 6 |  Power: 0.75 kW | Voltage 380 v/50 Hz Size: 4000*800*950mm Functions: After the potatoes are peeled, they enter this equipment, and then they are manually picked to see if there are any defective or unqualified potatoes, or if the skins have not been washed off, and do some processing. Remarks: PVC and 304 stainless steel; the conveyor belt speed can be adjustable. Waste conveyor |

| 7 |  Functions: feed trucks are placed on each side of the picking line. Waste materials can be conveniently put into it, and then dumped after each shift. | The material is 304 stainless steel. Size : 600*400*500mm Power: 2.2 kW |

| 8 |  Mashine ya kukata | Voltage : 380 v/50 Hz Size : 1200*1000*1400 mm Remarks : 304 stainless steel; thickness:7,9,10mm or according to client needs; Price includes 1 set of blade; Extra I set of blade 60 USD, only cut attached picture shape. Bucket elevator  |

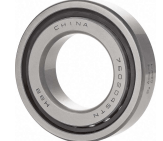

| 9 |  Power : 0.75KW | Voltage : 380V/50Hz Size : 1800*1000*1500mm The lifting mesh belt used is stainless steel 304 mesh belt, the mesh diameter is 3mm, the frame body used is 50 2mm high quality 304 stainless steel square tube and 2mm stainless steel, the bearing is stainless steel 316 bearing, the motor used is high quality copper wire adjustable speed Motor; frequency converter is Japan Mitsubishi frequency converter; electric is brand Schneider.50Dust cleaning machine |

| 10 |  Size : 2600*1000*1400 mm | Power : 1.5 kw Voltage : 380 v/50 hz Functions : After cutting the French fries, use a rinse machine to mention the top of the impurity removing machine. By setting the gap between the hair roller and the hair roller, generally 4mm soft hair roller, the fries go forward under the action of the hair roller, below The fries will leak out between the hair rollers, and there is a receiving box below to achieve the purpose of screening. Wool roller material is high-quality nylon wire and meets food requirements. Size : 6000*1200*1400mm |

| 11 |  Mashine ya kuosha kwa bubble | Nguvu : 5.5kw Voltage: 380v/50Hz Belt width : 800mm; machine length: 6m Through the bubble wave cleaning, the potato strips are rolled, and the starch and the like on the surface of the potato strips are fully washed, and the secondary water spray cleaning function is provided. Remarks: 304stainless steel; with wheels Heating Model : Electric heating |

| 12 |  Uwezo: 1200*700*950mm | Power : 120 kw Weight : 1400 kg Size : 1200*1000*1400 mm Size : 6000*1200*1400 mm Functions : After then, the chips enter the blanching machine. The mechanism stops the enzyme activity in the potato strips, maintains the original vivid color of the potato strips, improves the softness of the cells, and facilitates the evaporation of moisture. Through the bubble wave cleaning, the potato strips are rolled, and the starch and the like on the surface of the potato strips are fully washed, and the secondary water spray cleaning function is provided. Remarks: electric heating; the water temperature can be controlled; material 304 stainless steel; The mesh belt motor is a speed regulating motor and the thickness of the insulation layer is 70mm, which effectively prevents heat loss. Power : 0.55 kw |

| 13 |  Mashine ya kuondoa maji. | Size : 1800*1500*1300 mm Size : 1200*1000*1400 mm Functions : Blanched potato chips are conveyed to the vibration de-waterer through mesh belt, and the surface moisture is removed by high frequency vibration. Remarks : The material used in this machine is 304 stainless steel, the thickness of plate is 3mm, the frame square tube is 100 5mm high quality 304 stainless steel square tube50Power : 13.6 kw |

| 14 |  Mashine ya kukaanga kwa mfululizo | Voltage : 380 v/50 Hz Weight:700 kg Size : 5000*1200*1600 mm Belt width : 800mm; machine length: 5m After the fries are vibrated, they pass through the air-drying line to effectively and completely remove moisture. The working principle is that the cut potato strips are transmitted through a mesh belt and turned over several times to achieve the multi-faceted and uniformity of the material by the wind. Cool and dry the moisture on the surface of the potato strips. The air nozzle is designed as a knife, which effectively increases the air pressure, so that the moisture on the surface of the material is blown away in a short time, which is convenient for subsequent processes. Remarks: This air trunk line is all made of high-quality 304 stainless steel, frequency conversion speed regulation, mesh belt form is 6 turns and one flat, mesh belt width is 1200mm, 16 fans, each 0.75KW, the fan inlet uses a dense hole filter system, and the fan height is adjustable The bearing is a high-quality stainless steel bearing. Power : 0.75 kw |

| 15 |  Kuinua | voltage : 380 v/50 hz Size : 2000*1500*1350 mm Remarks : 304 stainless steel Power : 200 kw |

| 16 |  Mashine ya kukaanga | voltage : 380 v/50 Hz Weight : 1500 kg Size : 10000*1200*2400 mm Belt width : 800mm; machine length: 10m Functions : The working principle is as follows: after blanching and air-drying, the potato chips are raised from the hoist to the entrance of the fryer, the oil temperature is set to 185 degrees, the second oil temperature is set to 160 degrees, the third oil temperature is set to 120 degrees, and the potato chips are fried in the oil for about 1-2 minutes, then exported by the conveyor belt and enter the next deoiling process. This fryer is heated by electricity. Remarks : The equipment adopts pure frying technology and is equipped with dynamic filtering system. It realizes automatic filtering and slag discharging in the working process, guarantees the quality of frying oil. 304 stainless steel; variable frequency speed regulating motor, three-stage temperature control; equipped with automatic lifting function, which is conducive to cleaning and sanitation; equipped with electrical components are brand Omron or Schneider brand. Oil storage tank |

| 17 |  Kichujio cha mafuta | Upeo wa tanki la kuchuja kwa makali: 300mm Pampu ya mzunguko: 1.5kw Vifaa: chuma cha pua 304 |

| 18 |  Power : 1.5Kw/set | Stainless steel Thickness : 3mm Remarks : The material used in this machine is 304 stainless steel, the thickness of plate is 3mm, the frame square tube is 100*50*5mm high quality 304 stainless steel square tube |

| 19 |  Mashine ya kuondoa mafuta | Size : 1800*1500*1300 mm Size : 1200*1000*1400 mm Functions : Blanched potato chips are conveyed to the vibration de-waterer through mesh belt, and the surface moisture is removed by high frequency vibration. Remarks : The material used in this machine is 304 stainless steel, the thickness of plate is 3mm, the frame square tube is 100 Power : 13.6kw |

| 20 |  Mashine ya kukaanga kwa mfululizo | After the fries are vibrated, they pass through the air-drying line to effectively and completely remove moisture. The working principle is that the cut potato strips are transmitted through a mesh belt and turned over several times to achieve the multi-faceted and uniformity of the material by the wind. Cool and dry the moisture on the surface of the potato strips. The air nozzle is designed as a knife, which effectively increases the air pressure so that the moisture on the surface of the material is blown away in a short time, which is convenient for subsequent processes. Size : 1200*1000*1400 mm Belt width : 800mm; machine length: 5m After the fries are vibrated, they pass through the air-drying line to effectively and completely remove moisture. The working principle is that the cut potato strips are transmitted through a mesh belt and turned over several times to achieve the multi-faceted and uniformity of the material by the wind. Cool and dry the moisture on the surface of the potato strips. The air nozzle is designed as a knife, which effectively increases the air pressure, so that the moisture on the surface of the material is blown away in a short time, which is convenient for subsequent processes. Remarks : This air trunk line is all made of high-quality 304 stainless steel, frequency conversion speed regulation, mesh belt form is 6 turns and one flat, mesh belt width is 1200mm, 16 fans, each 0.75KW, the fan inlet uses a dense hole filter system, and the fan height is adjustable The bearing is a high-quality stainless steel bearing. Distributing machine |

| 21 |  Kuinua | voltage : 380 v/50 hz Size : 2000*1500*1350 mm Remarks : 304 stainless steel Power : 200 kw |

| 22 |  Size : 6000*1200*1300mm | Working principle : under the high frequency vibration of the vibrating motor, evenly distribute the potato chips on the quick-frozen net belt to prevent the chips from sticking together. Nguvu: 0.5kw The material used is 304 stainless steel, the thickness of the plate is 3mm, the square tubes of the frame are 100 * 50 * 5mm high-quality 304 stainless steel square tubes, the vibration motor is 0.25kw, and the vibration amplitude is adjustable. Mesh belt width : 1000mm Machine length: 11m |

| 23 |  Freezer | Size : 11000*2200*2400mm Quick freezing time : 7-35mim (adjustable) Feeding temperature : <15℃; Discharging temperature: -18℃ Temperature : -33~-35℃ Stainless steel thickness : outer thickness of the library plate 0.8mm, inner thickness 0.6mm, mesh belt bracket 50*50/3mm, guard plate 2mm Delivery value:3-6m³/h |

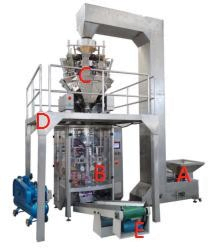

| 24 |  Mashine ya kufunga | A. Uwasilishaji wa chakula Dimension : 1780*1350*1950mm Voltage: 380v Uzito: 500kg B.TZ-720 Vertical Automatic Mashine ya kufunga Urefu wa mfuko: 100-400mm(L) Upana wa mfuko: 180-350mm(W) Upana wa roll film: 720mm Kasi ya kufunga: 5-50bags/min Mazingira ya kupimia: 6000ml (Max) Matumizi ya hewa: 0.65Mpa Matumizi ya gesi: 0.4m³/min Voltage: 220VAC/50HZ Nguvu: 5kw Vipimo: 1780*1350*1950mm Mashine ya Kiwango cha Mchanganyiko wa Maji C.10 Buckets Multi Head Weigher Uzito wa juu zaidi: 1000g Kiwango kimoja cha kupima: 10-1000 g Usahihi wa kupima: ±0.3~1.5 g Kasi ya kupima: Max 3000cc Kituo cha udhibiti: skrini kuu ya funguo la inchi 8.4 D.Platform Meza isiyo na skid, reli ya kinga kila upande, inayofaa na salama. Uwasilishaji wa bidhaa zilizomalizika |

Some details about French fries production equipment

| Hapana | Takwimu za kiufundi | Sehemu za ziada bure | Sehemu za ziada za malipo bure |

| 1 | Mkononi wa kontena la maji | Swichi ya kitufe 1 pcs Relays 2 pcs  | P206 bearing Block 2 Pcs 6905 bearing 2 Pcs  |

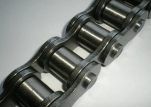

| 2 | Mashine ya kuosha kabla | Swichi ya kitufe 1 pcs Belt ya pembetatu 2 pcs  Mnyororo 1 Set  Sprayer 20pcs  | Roller ya brashi 9 pcs P206 bearing block 18 pcs Gurudumu la mnyororo 10 pcs  |

| 3 | Mkanda wa maji | Swichi ya kitufe 1 pcs Relays 2 pcs | P206 bearing Block 2 Pcs 6905 bearing 2 Pcs |

| 4 | Mashine ya peeling ya Emery | Swichi ya kitufe 1 pcs Belt ya pembetatu 2 pcs Mnyororo 1 Set Sprayer 20pcs | Rollers za Emery 4 pcs |

| 5 | Power: 0.75 kW | Swichi ya kitufe 1 pcs Relays 2 pcs | P206 Bearing Block 2 Pcs 6905 bearing 2 Pcs Mkanda wa conveyor 1 pcs  |

| 6 | Mashine ya kukata | Belt ya pembetatu 2 pcs | visu vya ukubwa tofauti 3 (7, 9, 12mm) |

| 7 | Power : 0.75KW | Swichi ya kitufe 1 pcs Relays 2 pcs | P206 bearing Block 2 Pcs 6905 bearing 2 Pcs |

| 8 | Size : 2600*1000*1400 mm | Swichi ya kitufe 1 pcs Relays 2 pcs Sprays 10pcs  | P206 Bearing Block 20 pcs Mnyororo 5 pcs  |

| 9 | Mashine ya kuosha kwa bubble | Swichi ya kitufe 1 pcs Relays 2 pcs Sprayer 10pcs | P206 bearing Block 2 Pcs 6905 bearing 2 Pcs |

| 10 | Uwezo: 1200*700*950mm | Swichi ya kitufe 1 pcs Relays 2 pcs Thermocouple 1 pcs  | P206 Bearing Block 2 pcs 6905 Bearing 2pcs Kudhibiti joto 1pcs  |

| 11 | Mashine ya kuondoa maji. | Swichi ya kitufe 1 pcs Relays 2 pcs | Mota ya vibration 2 Set |

| 12 | Mesh belt dryer | Swichi ya kitufe 2 pcs | Bomba la joto la umeme 3pcs Magari ya feni 2pcs P206 Bearing Block 2 Pcs 6905 Bearing 2 Pcs |

| 13 | Kuinua | Swichi ya kitufe 1 pcs Relays 2 pcs | P206 Bearing Block 2 Pcs 6905 Bearing 2 Pcs |

| 14 | Fryer | Swichi ya kitufe 1 pcs Relays 2 pcs | P206 Bearing Block 2 pcs P207 Bearing Block 2 pcs P206 Bearing Block 2 pcs |

| 15 | Kichujio cha mafuta | Swichi ya kitufe 1 pcs Vipengele vya Umeme 2 pcs Thermocouple 1 pcs | Bomba la joto la umeme 3 pcs Kudhibiti joto 1 pcs  |

| 16 | Mashine ya kuondoa mafuta | Swichi ya kitufe 1 pcs Relays 2 pcs | Mota ya vibration 2 Set Spring 4 Pcs |

| 17 | Mashine ya kupozea hewa | Swichi ya kitufe 1 pcs Relays 2 pcs | P206 Bearing Block 6 pcs P207 Bearing Block 2 pcs Feni ya hewa 2 pcs  |

| 18 | Kuinua | Swichi ya kitufe 1 pcs Relays 2 pcs | P206 Bearing Block 2 Pcs 6905 Bearing 2 Pcs |

| 19 | Size : 6000*1200*1300mm | Swichi ya kitufe 1 pcs Relays 2 pcs | Mota ya vibration 2 Set Spring 4 Pcs |

| 20 | Freezer cha kuendelea | Suction filter core 2pcs Mojawapo wa sehemu za kichujio cha maji 2pcs Sehemu ya kichujio cha mafuta 2pcs Solenoid valve coil 2pcs Mesh belt 1m Rapping block 2pcs Bima ya umeme 2pcs | Kipompo cha baridi cha maji ya evaporation 1 set Kipoo cha hewa cha evaporative 1 set Tundu la hewa la baridi ya haraka (joto la chini) 2 sets Valve ya kupanua ya Danfoss 2 pcs Valve ya sumu ya sumu 2 sets Mafuta ya barafu 1 pcs chupa Contactor ya compressor ya AC 2 pcs Contactor za AC nyingine 3pcs |

Air dryer

Mashine ya kuosha na kuondoa ngozi

- Rollers za nywele 9pcs.

- Tank ya maji ya mzunguko wa chujio chini inaweza kuokoa rasilimali za maji kwa ufanisi.

- Viazi huachwa kiotomatiki kupitia kiendeshi cha screw.

- Vifaa vinatengenezwa kwa chuma cha pua cha 304 chenye unene wa 3mm. Muundo umefanywa kwa chuma cha pua cha 304 cha 50*50*4mm. Mabawa ni ya chuma cha pua cha 316.

- Yenye Meza ya kuchukua Ina miguu inayoweza kurekebishwa na gurudumu la ujumla linaloweza kuondolewa kwa urahisi kwa urahisi wa usafiri.

Kiondoa maji kwa mitetete

- Magurudumu ya ujumla husonga na kuimarisha miguu.

- Kazi ya surfing inaweza kuongezwa, Sukuma nyenzo mbele, na udhibiti wa valve ya maji kasi.

- Spray ya shinikizo la juu, na spray ya pili, kuosha zaidi kwa usafi.

- Kibadilishaji cha mzunguko na kabati la kudhibiti umeme: kinaweza kuweka kasi ya kuosha.

Mashine ya kuosha haina uharibifu kwa mboga na matunda. Inaweza kutumika kusafisha mboga na matunda kama embe, limao, chungwa, jujube, nyanya, pilipili, nk.

Vifaa vinatengenezwa kwa chuma cha pua cha 304 chenye unene wa 2MM. Muundo umefanywa kwa chuma cha pua cha 304 cha 60 * 40 * 2mm. Vifaa vina miguu inayoweza kurekebishwa na gurudumu la ujumla linaloweza kuondolewa kwa urahisi wa usafiri, Vimewekwa na bahasha ya mzunguko wa kichujio, na spray ya maji ya shinikizo la juu.

QC system

- Yenye Ingizo la hewa la feni Inakubali mfumo wa kichujio cha mashimo mazito, urefu wa feni unaweza kurekebishwa, na gia ya chuma cha pua ya ubora wa juu.

- Kanuni ya kazi ni kuhamisha vipande vya viazi vilivyopikwa kwa kutumia mesh belt na kugeuza mara kwa mara ili kufanikisha upepo wa pande nyingi na usambazaji wa sawasawa wa nyenzo.

- Upepo wa shinikizo la juu wa blower huongeza baridi chakula na kuondoa unyevu kwenye uso wa vipande vya viazi.

- Urefu wa feni unaweza kurekebishwa kwa kurekebisha screw.

- Kuanza kwa funguo nyingi, udhibiti wa sehemu za idadi ya feni, ikiwa kundi moja limeharibika, mengine hayatathiriwa, na uzalishaji unaweza kupunguzwa bila kusitisha uzalishaji.

Ni huduma gani za thamani-tuongeza tunaweza kutoa?

Raw material procurement control

Tuna mfumo mkali wa kudhibiti ubora; kutoka kwa malighafi, uzalishaji, majaribio, usafirishaji hadi huduma za baada ya mauzo.

Production control

Kiwanda chetu kina idara maalum ya ununuzi, inayodhibiti kwa makini ununuzi wa malighafi. Sehemu zote kama vile visu, gia, sahani za chuma, funguo, nk, ni muhimu sana; hasa kwa mashine, sehemu muhimu zaidi ni sehemu ya umeme. Ikiwa kifaa cha umeme kitaharibika, mashine nzima itasimama kufanya kazi, kwa hivyo ni muhimu sana kuchagua kifaa cha umeme chenye ubora mzuri.

Tuna dhamana ya mwaka mmoja na tumeuza mashine nyingi kwa nchi tofauti. Hakuna mteja aliyeripoti matatizo hadi sasa.

Pre-shipment inspection

Wafanyakazi katika kiwanda chetu ni wataalamu wenye uzoefu, na wana uelewa mzuri wa muundo wa kila sehemu ya mashine; Teknolojia ya kulehemu ya kitaalamu.

Mtaalamu wa ubora wa bidhaa atatembelea mashine ya mfanyakazi mara kwa mara ili kukagua maendeleo ya kazi na matokeo; zaidi ya hayo, wataangalia bidhaa, kurekodi matokeo ya ukaguzi wa michakato ya ushonaji, kulehemu, na kupaka rangi ili kubaini kama mfanyakazi anadhibiti kwa kujitegemea kama matokeo yanakidhi mahitaji, haitahifadhiwa hadi itakapotangazwa kuwa na sifa.

Package system

Kabla ya kusafirisha, tutafanya utambuzi wa mashine na kuzijaribu na kuunda video kwa ajili yako. Ikiwa kuna tatizo la kutokidhi viwango, tutatengeneza mashine mpya kwa ajili yako, na kukupa punguzo la 5% kwa ununuzi ujao wa mashine kama pole ya dhati.

Storage system

- Mashine zimefunikwa kwa filamu ya plastiki kwanza kabla ya kufunga, ili kuepuka unyevu baharini.

- Mashine zimewekwa kwenye kesi ya mbao isiyo na sumu, ikiwa ni lazima, zikiwa na waya wa chuma.

After-sales service system

Tuna ghala maalum la kuhifadhi hisa, ambalo ni rahisi kwa wateja kusafirisha bidhaa kwa muda mfupi baada ya kuweka agizo.

If we cooperate, we can also provide the following services for free

- Bidhaa zote zinazunuliwa katika kampuni yetu zinahakikishiwa kudumisha hali nzuri kwa mwaka mmoja. Hitilafu zinazotokana na mashine na ubora zitachukuliwa na mtengenezaji wetu. Hitilafu nyingine zinazotokana na makosa ya uendeshaji, matatizo ya binadamu, nk, zitachukuliwa na mteja mwenyewe.

- Video ya uendeshaji & maelekezo itatumwa kwa wateja, kuwasaidia kutumia mashine kwa ufanisi zaidi.

- Ikiwa kuna matatizo yoyote wakati wa matumizi, ushauri wa kitaalamu utatolewa. Zaidi ya hayo, kampuni yetu hutoa msaada wa kiufundi na fittings kwa maisha. Huduma baada ya mauzo haijazuiliwa na muda na tutatatua matatizo yako kwa wakati. Ikiwa unakumbwa na matatizo wakati wa kutumia bidhaa zetu, karibu uwasiliane nasi wakati wowote.

- Mstari wa simu wa saa 24.

Detailed parameters of the whole

- Kiwanda chetu kitakuwa na tukio la matangazo kila robo mwaka, na kila tukio lijalo linaweza kukuhifadhi mahali.

- Ikiwa unataka kuwa wakala, tunaweza kukuza bidhaa kwa ajili yako na pia kupendekeza wateja wa eneo lako.

- Maoni ya tathmini: Mara moja kwa mwezi, fanya simu ya video na afisa anayesimamia kiwanda ili kukagua uendeshaji wa mashine. Kukusanya matatizo ili ushirikiano ujao ufanyike kwa urahisi zaidi.

- Ikiwa inawezekana, meneja wetu atatembelea mteja wetu wa ushirikiano kila mwaka, kupata mrejesho wa ziada na kujua soko la mteja mahali pao, tunatumaini kujenga uhusiano wa biashara wa muda mrefu, thabiti, na wenye ushawishi.