在伊拉克,薯条加工业务现在是一个非常受欢迎的投资项目。Taizy的薯条生产线和不同的深炸薯条加工方案受到许多伊拉克客户的青睐。为了满足不同客户的需求,我们为伊拉克及其他国家的客户配置了各种规格的薯条加工生产线供客户选择,如小规模薯条加工生产线、半自动薯条工厂、大规模薯条生产线等,产量在100kg/h到500kg/h之间。最近,又有一位伊拉克客户从我们的工厂订购了一条产能为200kg/h的深炸薯条生产线。

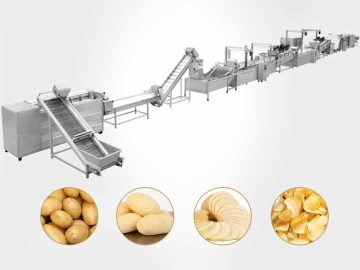

200kg/h薯条生产线配置

事实上,薯条生产线的产量是可以根据客户需求定制的,所以无论薯条加工商需要多大的薯条加工厂,我厂都能以优惠的价格提供加工方案。

200kg/h 薯条生产线通常包括刷式土豆清洗去皮机、土豆切割机、焯水机、自动脱水机、深炸机、脱油机、调味机和薯条包装机。

不过,伊拉克客户的工厂已经购买了一台产量为300公斤/小时的油炸机,所以这次只购买了薯条生产线的其他设备。

为什么伊拉克客户不生产冷冻薯条?

通常我们的80%客户会选择购买冷冻薯条加工线来生产冷冻薯条,因为冷冻薯条的生产成本较低,产量较大。然而,伊拉克客户选择生产新鲜的薯条。为什么是这样?

伊拉克客户选择加工新鲜薯条的主要原因是客户当地对新鲜薯条的需求量很大。顾客表示,虽然市内有很多快餐店出售新鲜薯条,但产量很小,每天的销量也很小。

这就导致了总是有很多买薯条的消费者排队买薯条的情况。客户分析,快餐店的薯条产量低,是因为他们选择手工制作薯条或购买冷冻薯条进行再加工,以节省成本。

客户认为他可以投资一条深炸薯条加工厂,大量生产酥脆的薯条,并将准备好的薯条分发到各个餐厅、快餐店、小吃店等。