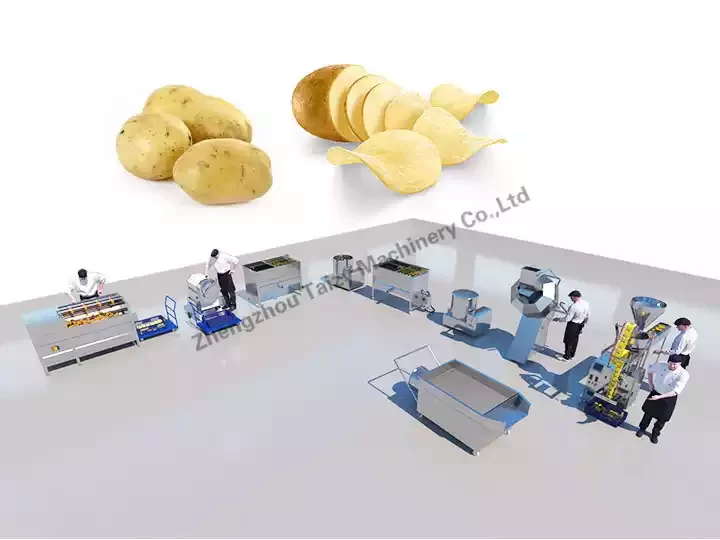

The 100kg/h potato chips processing plant is a small and medium-sized potato chip processing equipment. The main functions include potato cleaning, peeling, slicing, blanching, dehydration, drying potatoes, frying, degreasing, seasoning, and packaging. This commercial small-scale fried potato chip production line is very suitable for businessmen with limited investment funds. Potatoes, sweet potatoes, artichokes, etc. can all use this processing plant to produce crispy chips.

Required equipment of the 100kg/h potato chips processing plant

| Item | Gambar | Parameter |

| Mesin cuci dan kupas |  | Kapasitas: 700kg/jam Kapasitas: 600kg/jam Dimension: 16000*850*800 mm Voltage: 220v,50hz, single phrase Daya: 1,1kw Sikat: 9 Bahan: Baja tahan karat 304 Rol: 9 pcs Mesin dengan roda, semprotan, baki air Machine with wheels, sprays, and water tray. Collect the wastewater in the water tray to protect the sanitary environment |

| Daya: 2.2 kW |  | Kapasitas:600kg/jam Ukuran:750*520*900mm Fungsi: Ubi manis, kentang, lobak, dan lain-lain dapat dipotong, digunakan secara luas Berat: 70KG Daya: 0,75KW Material: all 304 Stainless steel Knife: 2mm or based on your needs Function: Sweet potato, potato, radish, and so on can be cut, widely used. |

| Mesin blanching |  | Model: TZ-700 Power:42kw Voltage:220v,50hz, single phrase Sikat: 9 Size:2200*700*950mm Daya:48kw Capacity:100 kg/h 50kg/batch (2 frames) Rol: 9 pcs One batch:1-2 minutes Function: to remove the starch |

| Dehydrating machine |  | Model: TZ-900 Dimensi:1600*850*800mm Size:1100*500*850mm Voltage: 220v,50hz, single phrase l Weight: 350kg Rol: 9 pcs One batch: 1-3 minutes Function: After blanching the potato chips, the potato chips’ surface has water, it can’t directly to frying, so it needs to use this machine to remove water. You can set the dewatering time by yourself |

| Mesin penggoreng |  | Model: TZ-700 Power:42kw Voltage:220v,50hz, single phrase Weight: 120kg Size:1200*700*950mm Capacity:100 kg/h Rol: 9 pcs Frying temperature:160-180℃ Function: fry the potato chips. The frying machine can provide a controllable constant temperature to keep uniform heating. The residue in frying oil can be filtered out automatically to ensure the oil quality. |

| Mesin penghilang minyak |  | Model: TZ-900 Dimensi:1600*850*800mm Dimensi:1100*800*1300mm Voltage: 220v,50hz, single phrase Berat: 180kg Weight: 350kg Rol: 9 pcs Function: after frying, use this machine to remove the surface oil. |

| Mesin bumbu |  | Model: TZ–800 Berat: 130kg Daya: 1,1kw Ukuran: 1000*500*700mm Voltage:220v,50hz, single phrase Rol: 9 pcs |

FAQ about the 100kg/h potato chips processing plant

How to pack the seasoned potato chips?

Deep-fried potato chips are crispy and can break easily when packaged. Therefore, we usually choose a potato chip packaging machine with a nitrogen filling function to pack potato chips. The vacuum packaging machine in our factory can not only vacuum packaging frozen French fries but also nitrogen-filled packaging for crispy foods such as potato chips.

Can potato chips be made into wavy shapes?

Yes, of course. The cutting knife of the potato slicer is replaceable. Users can purchase two cutters at the same time. The user can replace the potato cutter he needs on the potato slicer when using it. In addition, our company also provides the following potato slicers at a lower cost. The slicer has many feed ports with different diameters, which can be used to process potatoes of different sizes and other root vegetables, such as taro, sweet potatoes, etc.

Can the potato chip frying machine be heated by gas?

Absolutely yes. The potato chip frying equipment designed by our factory can be heated by gas and electricity. A gas-type fryer is more suitable for use in areas where power resources are not abundant. Moreover, compared with an electric fryer, a gas-type potato chip fryer can save processing costs.