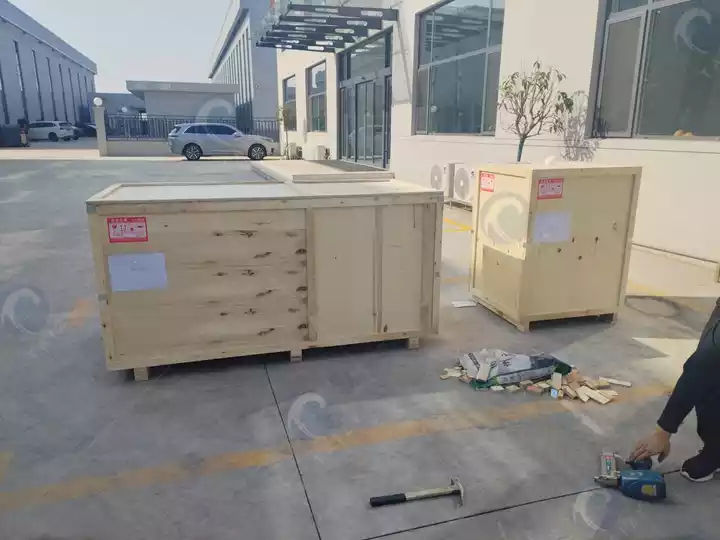

Мы отправили полную систему электрической машины для глубокого жарения клиенту из пищевой промышленности в Россию. Этот клиент специализируется на переработке и продаже закусочных продуктов, таких как картофель фри и чипсы. Внедряя оборудование для жарки, клиент стремится улучшить текстуру и гигиенические стандарты продуктов, повысить эффективность производства и снизить затраты на рабочую силу.

Конфигурация оборудования и ключевые параметры

В эту поставку входила машина для жарки TZ-2500, вакуумный масляный фильтр и конвейер длиной 2 метра, образуя полноценную систему непрерывной жарки и фильтрации масла.

Электрическая жарочная фритюрница (Модель: TZ-2500)

- Метод нагрева: электрический нагрев

- Мощность: 48кВт

- Напряжение: 380В, 50Гц, трехфазное питание

- Ширина ленты: 600мм

- Размеры: 2500×1000×1300мм

Регулируемая температура жарки до 230℃, с гибкими настройками времени жарки (например, примерно 2 минуты для хот-догов)

Универсальное применение для жарки картофеля фри, чипсов, куриных наггетсов, орехов, морепродуктов, лапшевых изделий и других продуктов.

Вакуумный масляный фильтр

- Мощность: 1,5кВт

- Напряжение: 380В, 50Гц, трехфазное питание

- Объем: 30л

- Размеры: 780×800×1000мм

Подключается напрямую к фритюрницам через трубопроводы и насосы для непрерывной фильтрации, эффективно поддерживая чистоту масла и продлевая срок службы.

Конвейер

- Длина: 2м

- Ширина ленты: 600мм

Высота конвейера, соответствующая выпускным отверстиям фритюрницы, обеспечивает плавный поток продукции и эффективную работу.

Преимущества и ценность применения машины для глубокого жарения

Эта система жарки обладает значительными преимуществами, включая высокую энергоэффективность, передовую автоматизацию и легкую очистку/обслуживание.

- Энергоэффективность: равномерный и стабильный электрический нагрев обеспечивает точный контроль температуры масла для стабильных результатов жарки.

- Гигиена и безопасность: вся установка изготовлена из нержавеющей стали 304 пищевого качества, соответствует стандартам безопасности пищевых продуктов для экспорта.

- Многофункциональный дизайн: подходит не только для производства картофеля фри и чипсов, но и для жарки куриных наггетсов, морепродуктов, орехов и различных других продуктов.

- Умная фильтрация: вакуумная система фильтрации масла постоянно очищает жиры в реальном времени, улучшая текстуру продуктов и снижая затраты на масло.

Интегрируя машину для жарки с масляным фильтром, клиенты достигают замкнутого производственного процесса с непрерывной жаркой и циркуляционной фильтрацией, что значительно повышает эффективность производства и качество продукции.

Обзор отзывов клиентов и перспективы сотрудничества

Во время выбора оборудования и разработки производственного плана наша техническая команда поддерживала тесную связь с клиентом, предоставляя индивидуальные проекты на основе их требований к выходу и планировке цеха.

Машина для глубокого жарения готова к немедленному запуску после прибытия. Клиент планирует расширение линии в будущем, вводя дополнительное оборудование нашей компании — бланшеры, обезжириватели, приправочные машины и упаковочные машины — для создания более комплексной автоматизированной линии обработки картофеля и картофеля фри.