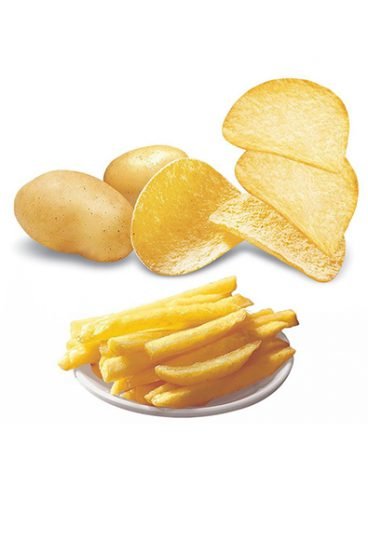

commercial potato chips and french fries processing line

whole set of chips and fries processing equipment

Everything here for helping to start your potato chips and frozen fries business

2 Sets of Vacuum Packing Machines Shipped to Canada

Potato Chip Production Line Shipped to Mexico

Semi-Automatic Frozen French Fries Processing Line to Spain

Fruit and Vegetable Bubble Washing Machine

Case of 2.5-Meter Mesh Belt Frying Machine Shipped to the UK

Potato Chips Manufacturing Line Successful Delivery to Botswana

Electric Deep Frying Machine Shipped to Russia

500Kg/h Brush Type Washing Machine Exported to South Africa

Fully Automated Banana Chips Production Line Shipped to Thailand

How Can I Choose the Right Potato Chips Production Line for My Business?

Delivery of Fully Automated French Fry Production Line to Canada

Mass production for frozen french fries

Taizy whole set of french fries machines can support you for mass production of frozen fries. No matter what kind of French fries processing equipment you need, we can meet your needs with best prices, such as full automatic French fries production line, semi-automatic French fries production line, 50kg/h,100kg/h,150kg/h,200kg/h,300kg/h,1-2T/h frozen fries plants, etc.

How to make wave chips and nomal chips?

Crisp potato chips with different shapes, such as flat shape and wave shape, can be produced with Taizy machines for commmercial purpose. We can customize the fully automatic and semi-automatic potato chips production lines that best meet your needs according to your potato type, desired potato chip thickness and shape, potato chips taste, potato chips packaging method, plant area, output requirements, investment budget and other factors.

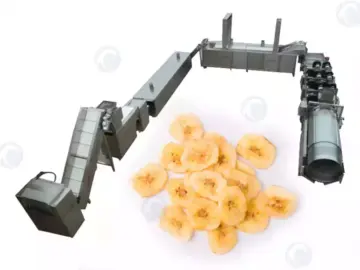

Fried banana chips processing craft

Due to the similar processing technology, Taizy machinery has also developed a series of equipment for producing fried banana chips. And with the advanced technology and high production efficiency, we have exported various types of fried banana chip production lines with different output to foreign countries and got very good feedback.

Useful tips you should know

01.

Fully automatic frozen fries processing craft

For industrial production of frozen french fries automatically, the producer should set an entire fries plant with a series of french fries making machines which include washing and peeling machine, slicer machine, blanching machine, frying machine, de-watering and de-oiling machine, quick freezer, packaging machine and auxiliary equipment.

02.

semi-automatic french fries production line

Based on the full-automatic frozen fries line, the semi-automatic french fries production line will be more flexible with labor working. Due to less investment costs, this semi-automatic fries line is very suitable for investors and small food processing plants in the early days of business.

03.

fully automatic potato chips processing line

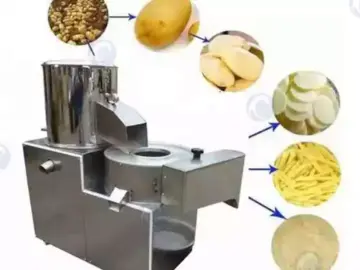

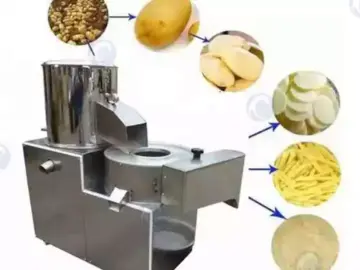

The processing technology of potato chips and fries is very similar, but there are some different processing steps. For example, when making potato chips, we use a potato cutter to slice the potatoes evenly (2mm). You can also use different cutters to make wavy potato chips. In addition, after the potato chips are fried, we can use an automatic seasoning machine to season the potato chips. The operation of the automatic potato chip production line is very intelligent, which can save a lot of labor costs and high production efficiency.

04.

semi-automatic potato chip making

The semi-automatic potato chip processing line eliminates a lot of automatic conveying equipment.And the blanching machine and the fryer in the semi-automatic potato chip production line can use the same equipment, as well as the dehydrator and deoiler, which can save a part of the investment cost and is more suitable for small and medium food processing plants with low investment budget.

05.

Fried banana chips production line knowledge

The fried banana chip production line also has automatic and semi-automatic production equipment. The processing capacities of the production line can be matched with different equipment according to customer needs. The production process of fried banana chips mainly includes peeling, slicing, frying, de-oiling, seasoning and packaging.

Taizy——Leading brand for fries and chips machinery manufacturing

Quality and customizable equipment. Competitive and reasonable prices. Comprehensive and thoughtful customer service. Complete production solutions. Prompt delivery and after-sales tracking.