The automatic potato chips processing line is the equipment used to produce crispy potato chips. The potato chip processing industry has a good development prospect. We have a complete set of potato chip processing machines, from potato cleaning to potato chip packaging. The following is related to the potato chip production machine.

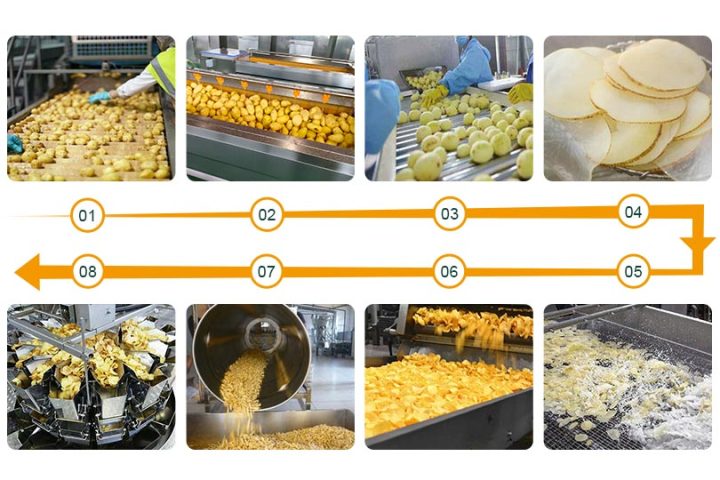

The production process of the automatic potato chips processing line

Washing and peeling-cutting into strips or slices-blanching-dehydrating-frying-deoiling-seasoning-packaging, the process of producing potato chips is very simple, First, peel the potatoes and wash them. The washing machine can carry out washing and peeling at the same time. Then use a belt conveyor to feed the peeled potatoes to the slicer. The potatoes are cut into thin slices as needed. And wash the free starch with water. The cleaned potato chips are sent to the blanching machine for blanching, and the cleaned and blanched potato chips carry a large amount of attached water. Use a dehydrator to remove the moisture on the surface of the potato chips, and the oil content in the finished product of fried crisps is between 30%-40%.

After frying, the potato chips are transported to the degreasing machine to drain the remaining oil on the surface of the product. The fried potato chips are transported to the drum seasoning machine to season the potato chips, and different seasonings are added according to different products. Then the seasoned potato chips are transported to the packaging workshop, and the products are packaged into the required size and shape.

Introduction of raw materials for potato chips production

Potato is a kind of economic crop with a high yield, strong adaptability, wide distribution, rich nutrition, and high economic price. Fried potato chips are made from fresh potatoes after washing, peeling, slicing, and seasoning. This kind of convenience food is deep-fried at high temperatures for a short time and dehydrated quickly. Compared with traditional processing methods such as frying and stewing, it effectively prevents the water-soluble nutrients in potatoes from being lost during processing.

How to choose potato chips?

The quality of raw materials has a direct impact on the quality of finished products. Different varieties of potatoes have obvious differences in their dry matter content, color inside the potato, depth of buds, reducing sugar content, solanine content, and polyphenol oxidase content. When choosing potatoes, you should choose fresh potatoes with low starch content, and require pure varieties, shallow sprouts, regular shapes, no mildew, rot, sprouting, and insect pests. The selected raw materials are sent into the hopper, and the raw materials are weighed through a belt conveyor, and at the same time, they are selected to remove moldy potato blocks and rotten lumps.

Features of large automatic potato chips processing line

- It not only keeps the frying oil clean, improves the product quality, and extends the shelf life, but also brings higher added value to the product.

- Advanced mechanical configuration and control can always maintain good working conditions, which not only increases the output but also makes the product quality stable, and the color, fragrance, and taste are unified.

- The automatic filtering of this machine can greatly extend the service life of frying oil without frequent oil changes. The oil consumed during the frying process of the product is equivalent to the oil absorbed by the product, saving fuel efficiency

Benefits of automatic potato chips processing line

The biggest advantage of using the frying line is high automation, time-saving, labor-saving, low labor intensity, etc, and the product quality is stable, the output is high, the cost is low, and it is green and pollution-free. French fries frying assembly line, the frying time is controllable, the frying time can be adjusted freely according to the product demand, and the oil temperature can be controlled in detail and accurately so that the food can be fried at the best temperature and the product quality can be improved.

The frying line has a good temperature control effect. After feeding, the overall oil temperature fluctuation range is controlled within 2 degrees, which reduces the energy loss of re-heating, saves production time, and improves efficiency. The fried French fries production line is a mesh belt frying assembly line. According to the size requirements of the product, the network bandwidth and mesh size are adjusted. The whole machine is made of high-quality stainless steel, strong and durable, with strong corrosion resistance, a beautiful appearance, and strong applicability.

Specific machines included in the automatic potato chips processing line

1. Hoist

The raw potatoes go through the elevator and enter the pre-washing machine for cleaning, mud, and stone removal. Power 1.5kw ,size: 6000*1200*1600mm

2. Potato washing machine

After being lifted, the potatoes enter the pre-washing machine, and the soil on the surface of the potatoes is cleaned by hair rollers and sprays, and then enters the next step. Power 4.37kw, size:3400*1400*1400mm.

3. Wash and peel machine of automatic potato chips processing line

The pre-washed potatoes enter the peeling machine through the elevator and are thoroughly peeled by the emery roller and wool roller. The number of hair rollers used is 5, the number of emery rollers is 4, and the bottom is equipped with a circulating filter water tank, which can effectively save water resources. Potatoes are automatically discharged by screwing, and the peeling time can be adjusted. The frames used are 50504mm high-quality 304 stainless steel square tubes and 3mm stainless steel, and the bearings are stainless steel 316 bearings. power : 5.87kw size: 3400*1400*14005.

4. Picking conveyor

After the potatoes are peeled, enter this equipment, and then manually pick them to see if there are broken spots or unqualified potatoes, or unwashed skins, and do some treatment. This picking line adopts PVC high-quality food-grade conveyor belt, which is safe and sanitary and meets food requirements. The plate used is 304 high-quality stainless steel, size: 6000*800*950mm, power: 0.75KW/380V/50Hz

5. potato chips cutter of automatic potato chips processing line

Qualified potatoes are automatically entered into the potato chip machine through the picking line, and the potato chip machine continuously completes the cutting work. The size is 20006001200mm, the output is 1500kg/hour, the blade is made of high-speed stainless tool steel, the turntable is made of high-quality aluminum-magnesium alloy, and the rest is made of 304 stainless steel, with a thickness of 2mm.

6. Bubble washing machine

The potato chips fall directly into the rinsing machine, and the potato chips are tumbling through the bubble and wave washing, so that the starch on the surface of the potato chips is fully washed, and it is equipped with a secondary spray cleaning function with water. Size: 6000x1400x1300mm,Power: 6.6KW/ 380V/50Hz

7. Air cooling machine

The air inlet of the fan adopts a dense hole filter system, the height of the fan is adjustable, the bearing is high-quality stainless steel bearing, and the nozzle is designed as a knife, which effectively increases the air volume pressure so that the moisture on the surface of the material is blown away in a short time, which is convenient for subsequent processes, The bottom of the air trunk line is equipped with a drain pan. Overall dimensions of the air trunk line 6000x1200x1600mm,Power: 60kw/ 380V/50Hz 3 phase

8. Fryer of automatic potato chips processing line

The equipment adopts pure oil frying technology, is equipped with a dynamic filtering system, with a circulation device, realizes automatic filtering and slag removal during the working process, ensuring the quality of frying oil, and the power is 160kw, Size: 10000x1400x2200mm

9. Oil storage tank

Oil storage tank with heating function, filter screen, a thickness of 3mm, and insulation layer. Oil pump motor power: 1.5KW/ 380V/50Hz*

External dimensions: 1400x1300x1850mm

10. Oil tank storage

When the equipment is working, the oil in the frying machine first enters the coarse filter under the action of the internal and external pressure difference, and then enters the fine filter through the circulating pump. Under the action of the fine filter paper, the ultrafine particles in the oil are removed. The sundries are filtered out, and the oil flowing from the oil outlet is the oil that meets the requirements. It is connected to the fryer through the pipeline to complete the dynamic filtering, thereby completing the entire filtering process

11. Fuel tank

The fuel tank is equipped with a heating device, and the oil that needs to be added is heated to a certain temperature through the heating pipe, and then sent to the inside of the fryer through a circulating pump to achieve the purpose of adding oil.

12. De-oil machine

Under the high-frequency vibration of the vibration motor, the oil on the surface of the potato strips is fully removed, and the material advances into the air mainline under the vibration state. Size: 1800*1000*1300mm Power: 0.25KW

13. Roller seasoning machine for potato chips

Different flavors of potato chips are seasoned in a potato chip seasoning machine. The drum seasoning machine is a potato chip seasoning machine that can carry out continuous production, automatic feeding, and automatic discharging.

15. packing conveyor