The industrial French fries production line is the general term for a series of complete French fries making machines, mainly including potato washing machine, potato peeling machine, potato cutting machine, potato strip blanching machine, automatic dehydrator, French fries frying machine, automatic deoiling machine, fried French fries seasoning machine, French fries packaging machine and supporting auxiliary equipment, such as mesh belt conveyor, hoist elevator, manual picking table, etc.

The automatic and semi-automatic French fries processing line is mainly based on processing potatoes, and can also process sweet potatoes and taro into crispy French fries. At present, various types of French fries processing plants have been exported to Turkey, Iraq, Egypt, the United States, Saudi Arabia, Morocco, Russia, UAE, Peru, etc.

The production capacity of the small French fries production line is 50kg/h, 100kg/h, 150kg/h, 200kg/h, 300kg/h, etc. The output of large-scale French fries processing plant is 300kg/h, 400kg/h, 500kg/h, 800kg/h, 1000kg/h. Of course, the French fries production line with larger output can be customized according to customers’ production needs.

Automatic Frozen French fries processing plant 3D animation video

Why choose French fries production business?

The reason why the French fries production business is the important investment project of choice for many investors is that it can create considerable profits. French fries and potato chips are the most popular casual snacks in the world, and their crispy taste is liked by people of any age, so their market demand is very large.

In addition, the process of processing French fries is not complicated, and the processing cost is not high, so it is very suitable for small, medium, and even large French fries processing plants. With less manual participation and a higher return on investment, the commercial french fries making machines are very popular on the global market now.

Frozen french fries VS deep-fried french fries

The main difference between frozen french fries and fresh french fries lies is in the frying process. When frying, at the same frying temperature (160-180 ℃), the frying time of frozen french fries is shorter, about 40-60 seconds.

While the frying time of deep-fried french fries is about 5 minutes. In addition, the freshly fried french fries can be eaten after frying, while the frozen french fries need to be re-fried once to be eaten.

Classification of Taizy French fries processing machines

As a professional food machinery manufacturer and supplier at home and abroad, Taizy machinery has been supplying a series of food processing equipment to the domestic and foreign markets for 10 years. Among them, the French fries making machine is the main product of our factory.

Taizy’s French fries processing machinery has many types, models, specifications, and output. Usually, we divide the fries production line into the small semi-automatic French fries production line and large automatic French fries production line according to different configurations.

Semi-automatic French fries production line

Semi-automatic french fries processing lines have been exported to dozens of countries for small and medium-sized french fries plants. With remarkable profits, the semi-automatic french fries lines with capacities of 50kg/h, 100kg/h, 200kg/h, 300kg/h, and 500kg/h are on hot sale now.

Machine list of semi-automatic french fries processing plant

| Name | Picture | Technical data |

| Potato washer and peeler |  | Capacity:200kg/h Dimension:1600*850*800mm |

| Potato slicer |  | Capacity:600kg/h Dimension:950*800*950mm |

| Blanching machine |  | Capacity:200kg/h Dimension:1200*700*950mm |

| Dewatering machine |  | Capacity:200kg/h Dimension:1100*500*850mm |

| Frying machine |  | Capacity:200kg/h Dimension:1200*700*950mm |

| De-oil machine |  | Capacity:200kg/h Dimension:1100*500*850mm |

| Seasoning machine |  | Capacity:300kg/h Dimension:1100*800*1300mm |

| Packaging machine |  | Capacity:300kg/h Dimension:1200*600*850mm |

Note: The parameters of all the above machines are only based on the configuration of a french fries production line with an output of 200kg/h. These machines actually have different models and capacities, we can match the most suitable machine for customers according to their actual production needs.

Workflow of the small French fries processing line

The industrialized production of fried French fries is becoming more and more popular in the international market. Many investors have gradually established their own french fries processing plants, and large-scale production of french fry has become a major market trend.

The main process of processing french fries in the factory is: potato washing and peeling, potato cutting (size adjustable), potato strip blanching (80 ℃ -100 ℃), rapid dehydration, frying (160 ℃ -180 ℃), quick deoiling, seasoning, french fries packaging.

Details about the semi-automatic French fries production plant

1. Potato washing and peeling. For different kinds of potatoes, the machine can replace brushes of different hardness. It can quickly clean potatoes and peel them, and even polish the surface of potatoes.

2. Potato strips cutting. The working efficiency of the automatic potato strips cutting machine is very high, and the processing volume per hour can reach 600kg. The cutting size of potato strips can be adjusted by changing different cutting blades.

3. Potato strips blanching. The same equipment can be used for the blanching machine and frying machine in the semi-automatic fries processing line. The main purpose of blanching is to remove the excess starch on the surface of the potato strips and prevent their oxidation from blackening.

4. Dewatering. In order to save the frying time of french fries and improve the safety of frying work, the blanched potato strips should be dehydrated quickly. Similarly, the dehydrator and deoiler of the semi-automatic fries line are the same equipment.

5. Potato strips frying. The frying temperature of french fries is about 160 ℃ -180 ℃, and the time is 3-5 minutes. Customers can set the frying temperature within this range according to their own potato types.

6. Fries deoiling. The main purpose of deoiling is to remove the excess oil on the surface of the french fries and ensure that the french fries have a good taste.

7. French fries seasoning. In order to make crispy fries with different flavors, fries processors can use the seasoning machine to season fried fries. The automatic seasoning machine can fully mix French fries and seasonings through continuous rotation, and stir evenly.

8. French fries packaging. The french fries will not stick to each other, so it is easy to pack them with a vacuum packaging machine. The packaged french fries are easy to transport to various restaurants and fast-food restaurants.

Small French fries processing plant working video

Fully-automatic french fries processing plant

The fully automatic French fry processing line is highly automated and intelligent. The complete french fries making machines are suitable for large-scale French fries plants, but also suitable for small and medium-sized potato fries processing plants.

Compared with the semi-automatic French fries line, the automatic French fries production line adopts automatic conveying equipment in the main production links, thus replacing a lot of manual labor, reducing manual participation, so the production process is more hygienic.

Machine list of the automatic french fries production line

| NO. | Equipment name | Equipment picture |

| 1 | Hoist conveyor |  |

| 2 | Potato washing and peeling machine |  |

| 3 | Picking line |  |

| 4 | Potato strips cutter |  |

| 5 | Hoist conveyor |  |

| 6 | Dust remover |  |

| 7 | Rinsing machine |  |

| 8 | Blanching machine |  |

| 9 | Vibration water remover |  |

| 9 | Air cooler |  |

| 10 | Hoist conveyor |  |

| 11 | Continuous frying machine |  |

| 12 | Vibration oil remover |  |

| 13 | Air cooler |  |

| 14 | Hoist conveyor |  |

| 15 | Rotary seasoning machine |  |

| 16 | Automatic packaging machine |  |

Note: The machine configuration of the fully automatic french fries processing line is very flexible, we need to match the suitable machines according to customer needs. This list of machines can be used as a reference, basically covering the automatic production process of French fries. Moreover, some of the production links can be adjusted and changed according to actual production needs.

The processing flow of fully automatic french fries line

1. Hoist conveyor in automatic fries line. The hoist conveyor plays an important role in the mass production of frozen french fries. Its main function is to automatically complete the transportation of materials and reduce manual participation.

2. Automatic washing and peeling equipment can remove the dirt and skins of potatoes quickly. For automatic processing, it is designed with an inner screw for pushing the clean potatoes forward.

3. The setting of the picking line(table) is for labor picking out of the bad potatoes so that it can ensure the french fry quality.

4. Potato strips cutter machine can cut potatoes into even strips, and the final potato strips size can be adjusted. For large scale french fries processing, this machine can be set up more than one.

5. The dust remover and rinsing machine are mainly used for deep processing the potato strips, such as to remove the hair and other debris.

6. Blanching machine is needed for removing the starch on the surface of the potato strips, and achieve the purpose of color protection.

7. In order to achieve better and faster dewatering and deoiling effects, the de-water and de-oil equipment of the fully automatic french fries line have been replaced by a combination of vibration water remover (oil remover) and automatic air cooling equipment.

8. The continuous frying machine can be gas-heating and electric-heating so that the customers can choose freely. Besides, the temperature control and materials transporting speed are adjustable to this machine.

9. The rotary seasoning machine is often used in large food processing lines. The French fries seasoning machine has the functions of automatic weighing and automatic feeding. It can add a certain amount of seasoning to the roller regularly, so as to ensure the consistent taste of French fries.

10. This ten-bucket packaging machine is a fully automatic packaging machine with the best packaging effect and highest efficiency in the current market. Its packaging size and packaging weight can be customized. In addition, nitrogen filling and coding can also be performed.

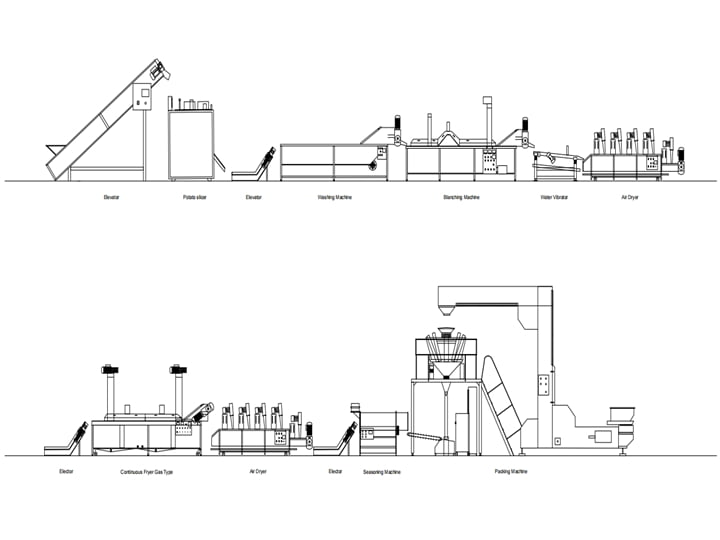

drawing line of full-auto potato chips line

Large French fries processing plant working video

Features of the Taizy French fries production line

1. Each of the machines of the whole french fries line is made of high-quality 304 stainless steel. It can not only ensure food hygiene but also ensure that the machine has a long service life.

2. We can not only provide customers with the most cost-effective french fries making machines, but also can provide overall solutions for fries production. For example, according to the customer’s potato types, plant area, investment budget, output requirements and other customized production lines that meet customer requirements.

3. We can even do a complete market analysis and profit analysis for our customers for free so that customers can see the prospect of investing in french fries processing.

4. No matter how large french fries processing plants that the customers need, we are fully capable of providing the corresponding production equipment.