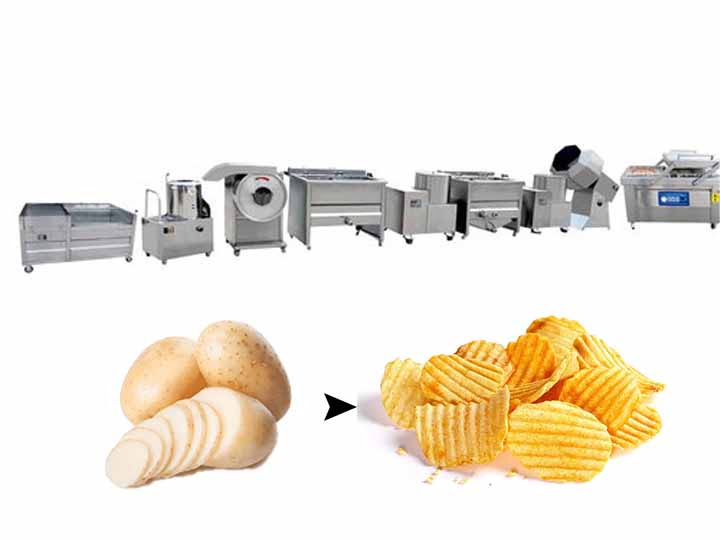

The 50kg/h potato chip production line is the smallest potato chip processing equipment that our factory can provide. The potato chip processing line is suitable for small-scale food factories and self-employed customers with low investment budgets. It has the characteristics of low cost, complete functions, and high return on investment.

The main equipment of this mini potato chip processing line includes the potato washing and peeling machine, potato slicer, potato chip blanching machine, automatic dehydrator, potato chip frying machine, automatic deoiling machine, octagonal seasoning machine, and potato chip packaging machine.

Machine details of the 50kg/h potato chip production line

| Name | Picture | Parameter |

| Potato washing and peeling machine |  | Model: TZ-300 Power: 0.55kw Capacity: 300kg/h Size: 600*430*800mm Weight: 70kg The model has a small footprint, with a cleaning and peeling function. |

| Chips cutting machine |  | Model: TZ-600 Size:750*520*900mm Weight:70kg Power:0.75KW Capacity: 300-600kg/h The most professional fries machine, the shape of the cut potato chips looks good, the thickness is even. |

| Blanching machine(Electric heating) |  | Model: TZ-500 Size:700*700*950mm Weight:70kg Power:12kw Capacity:50kg/h Material:304 stainless steel You can also choose gas heating. The purpose of blanching is to remove starch. |

| De-water machine |  | Model :TZ-400 Size:1000*500*700mm Weight:360kg Power:1.5kw Capacity:300kg/h |

| Frying machine(Electric heating) |  | Model: TZ-500 Size:700*700*950mm Weight:70kg Power:12kw Capacity:50kg/h Material:304 stainless steel Gas heating is also available. The purpose of blanching is to remove starch. |

| De-oil machine |  | Model :TZ-400 Size:1000*500*700mm Weight:360kg Power:1.5kw Capacity:300kg/h |

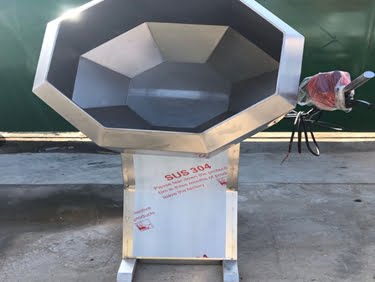

| Seasoning machine |  | Model:TZ-800 Size:1000x800x1300mm Weight:130kg Power:1.5kw Capacity:300kg/h |

| Electronic scale |  | Model:TZ-211 Size:770*370*345mm Weight:11.7kg |

| Sealing machine |  | Model: TZ-200 Size: 844*375*320mm Motor Power: 50w Sealing power: 600w Speed:0-12m/min Seal width: 10mm Weight:23kg Power:220v,50hz Temperature range:0-300°C Distance from sealing center to conveyor: 20-40mm Conveyor size:844*153mm Max conveyor load for single bag:≤1kg Overall conveyor load:≤3kg |

Note for the 50kg/h semi-automatic potato chips production line

The heating method of the blanching machine and frying machine in this small potato chip processing line can be electric heating and gas heating. Customers can choose according to their own production needs. If gas heating is used, an additional burner needs to be purchased to ignite combustible gas.

The 50kg/h potato chip processing plant designed by our factory has largely saved the user’s cost. For example, in the packaging of potato chips, we recommend low-cost weighing devices and automatic sealing machines. Of course, if the customer needs an automatic potato chip packaging machine, we can also provide it.

The packaging style, weight, and packaging type of potato chips are all determined by the customer. Our factory can provide customers with the most cost-effective processing and packaging equipment according to their needs. The functions of the potato chip packaging machine include ordinary packaging and nitrogen-filled packaging.