Pabrik keripik kentang ini adalah lini produksi kentang goreng 150/jam. Ini adalah peralatan berukuran sedang dengan semua mesin produksi dari kentang hingga pengemasan keripik kentang. Proses produksi kentang goreng meliputi pencucian kentang dan pengupasan, pemotongan kentang, blanching, dehidrasi, penggorengan, de-oiling, bumbu, dan pengemasan.

Perbedaan proses pembuatan kentang goreng dan keripik kentang

Selain bentuk yang berbeda dalam proses produksi kentang goreng dan keripik kentang, masih ada beberapa perbedaan. Pertama, bentuk potongan dan ketebalan keripik kentang dan kentang goreng berbeda, ini menyebabkan waktu penggorengan yang berbeda untuk kentang goreng dan keripik kentang, dan waktu penggorengan untuk kentang goreng relatif lebih singkat. Beberapa orang mungkin menganggap ini tidak percaya. Meskipun kentang goreng lebih tebal daripada keripik kentang, kebanyakan dari mereka digoreng ringan, dibekukan, lalu dikemas dan dijual. Keripik kentang dijual langsung sebagai produk jadi.

| Item | Gambar | Rincian |

| 1. Mesin pencuci dan pengupasan |  | Kapasitas: 700kg/jam Kapasitas: 700kg/jam Dimensi: 1580*850*800 mm Tegangan: 380v, 50hz, 3 fase Daya: 1,1kw Berat: 180kg Satu batch: 2 menit Rol: 9 pcs Rol: 9 pcs Mesin dengan roda, semprotan, baki air. |

| 2. mesin pemotong |  | Mesin pemotong kentang Kapasitas:600kg/jam Ukuran: 750520900mm Berat: 70KG Daya: 0,75KW Fungsi: Ubi manis, kentang, lobak, dan lain-lain dapat dipotong, digunakan secara luas |

| 3. Mesin blanching |  | Model: TZ-1500 Daya: 36kw Tegangan: 380v, 50hz, 3 fase berat: 100kg ukuran: 1700*700*950mm Daya:48kw Kapasitas: 150kg/batch (3 frame) Bahan: Baja tahan karat 304 Satu batch: 1-2 menit |

| 4. Dehidrator |  | Kapasitas: 300kg/jam Kapasitas: 300kg ukuran: 1000*500*700mm Tegangan: 380v, 50hz, 3 fase daya: 1,5kw Waktu: 1-3 menit Bahan: Baja tahan karat 304 Waktu: 1-3 menit Fungsi: Setelah blanching kentang, permukaannya berair, tidak bisa langsung digoreng, jadi perlu menggunakan mesin ini untuk menghilangkan air. Anda dapat mengatur waktunya sendiri. |

| 5. Mesin penggoreng |  | Model: TZ-1500 Daya: 36kw Tegangan: 380v, 50hz, 3 fase berat: 100kg ukuran: 1700*700*950mm Jenis pemanas: listrik kapasitas: 150L Kapasitas: 150kg/batch (3 frame) Bahan: Baja tahan karat 304 Waktu penggorengan: 1,5-2 menit Suhu: 160-180°C |

| 6. Mesin penghilang minyak |  | Kapasitas: 300kg/jam Fungsi: setelah menggoreng keripik kentang, gunakan mesin ini untuk menghilangkan minyak permukaannya, lalu ke mesin pembeku. Dimensi: 1000*500*700mm Tegangan: 380v, 50hz, 3 fase Berat: 180kg Waktu: 1-3 menit Rol: 9 pcs Ukuran: 1900*940*2150mm |

| 7. Mesin bumbu |  | Model: TZ–800 Berat: 130kg Berat: 180kg Fungsi: setelah menggoreng keripik kentang, gunakan mesin ini untuk menghilangkan minyak permukaannya, lalu ke mesin pembeku. Tegangan: 380v, 50hz, 3 fase Bahan: Baja tahan karat 304 Desain sederhana, menghemat biaya, tetapi tidak mempengaruhi fungsi dan efisiensi produksi. |

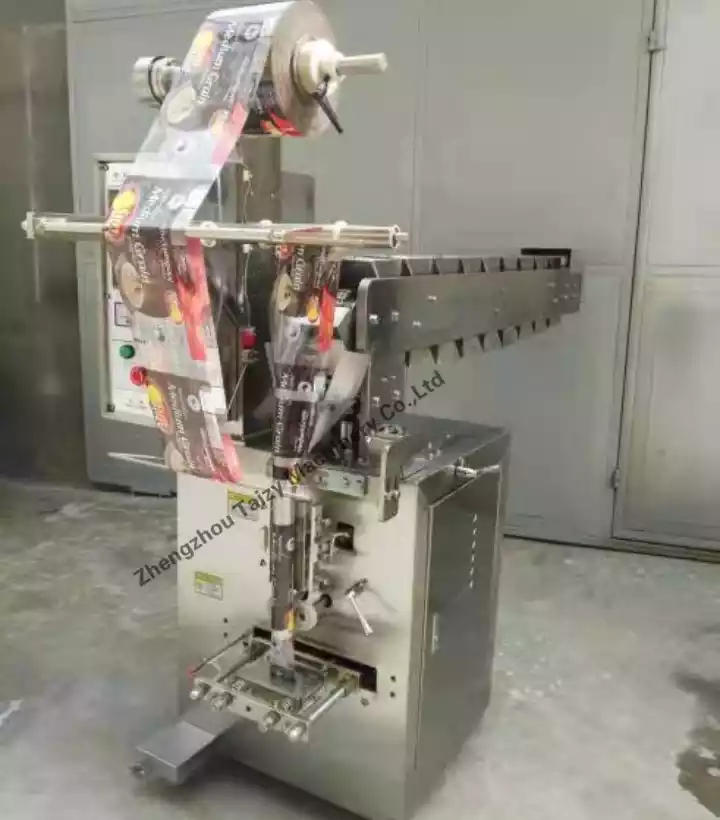

| 8. Mesin pengemasan keripik kentang |  | Model: TZ-450 mesin pengemasan Daya: 2,2kw Kecepatan pengemasan: 20-80 kantong/menit Panjang kantong: 30-300mm (dapat disesuaikan) Lebar film gulung: 40-450mm (perlu mengganti Pembentuk) Gaya kantong: penutup belakang, penutup 3 sisi, penutup 4 sisi Berat: 420kg Dimensi: 75011502100mm |

| 9. Rangka untuk mesin de-oil |  | Jumlah: 2 set harga satuan: 90usd Tinggi: 300mm Diameter: 500mm Berat: 9 kg |

| 10. Rangka untuk mesin penggoreng |  | Jumlah: 2 set Harga satuan: 80usdUkuran: 490*490*260mmBerat: 5kg |

| 11. Tabung pemanas |  | Jumlah: 6 pcs harga satuan: 50usdBahan: Baja tahan karat 304 pipa tanpa sambungan |

Berapa lama kentang perlu dibersihkan?

Untuk waktu pembersihan kentang, ada dua situasi. Pertama, jika kentang segar digunakan untuk produksi, waktu pembersihan biasanya 1-2 menit. Namun, jika menggunakan kentang stok, waktu pembersihan akan lebih lama, biasanya 5-6 menit.

Berapa ketebalan irisan kentang yang dipotong oleh pemotong?

Mesin dapat memotong keripik kentang antara 2-9mm, tetapi ketebalan keripik kentang dalam proses produksi biasanya antara 1-2mm. Jika terlalu tipis, akan menyebabkan kentang rapuh selama proses penggorengan. Jika terlalu tebal, akan mempengaruhi rasa, jadi ketebalan irisan kentang sangat penting.

Selain itu, irisan keripik kentang harus seragam, sehingga panas dapat dikontrol dengan lebih baik selama tahap penggorengan.

Mengapa kentang harus diblanching di pabrik produksi keripik kentang

Karena kentang adalah sayuran dengan kandungan pati yang cukup tinggi, blanching dapat menghilangkan pati di permukaan kentang, membuat keripik kentang lebih renyah saat digoreng, dan menghindari terlalu banyak pati yang dapat menyebabkan keripik kentang menjadi terlalu lembek. Selama proses blanching keripik kentang, mesin perlu dipanaskan terlebih dahulu selama 15-20 menit pada suhu 80℃-100℃, tetapi waktu blanching tidak boleh terlalu lama, biasanya sekitar 1 menit.