This potato chips production plant is a 150/h French fries production line. It is medium-sized equipment with all production machines from potatoes to potato chip packaging. The production process of potato fries includes potato washing and peeling, potato slicing, blanching, dehydration, frying, de-oiling, seasoning, and packaging.

The difference between French fries and potato chips production plant process

In addition to the different shapes in the production process of french fries and potato chips, there are still some differences. First, the cutting shape and thickness of potato chips and french fries are different, this results in different frying times for French fries and potato chips, and the frying time for fries is relatively shorter. Some people may find it incredible. Although French fries are thicker than potato chips, most of them are lightly fried, frozen, and then packaged and sold. Potato chips are sold directly as finished products.

| Item | Picture | Details |

| 1. Washing and peeling machine |  | Model: TZ-800 Capacity: 700kg/h Dimension: 1580*850*800 mm Voltage: 380v,50hz,3 phase Power: 1.1kw Weight: 180kgOne batch:2 minutes Material: 304 stainless steel Rollers: 9 pcs Machine with wheels, sprays, water tray. |

| 2. cutter machine |  | potato cutting machine Model: TZ-600 Size:750520900mm Weight:70KG Power:0.75KW Capacity:600kg/h |

| 3. Blanching machine |  | Model: TZ-1500 Power:36kw Voltage:380v,50hz,3 phase weight: 100kg size:1700*700*950mm Heating type: Electric Capacity:150kg/batch (3 frames) Material: 304 stainless steel One batch:1-2 minutes |

| 4. Dehydrator |  | Model: TZ-400 Capacity:300kg/ size:1000*500*700mm Voltage:380v,50hz, 3 phase power:1.5kw Weight: 360kg Material: 304 stainless steel Time: 1-3 minutes Function: After blanching the potato, the surface has water,it can’t directly to frying, so it needs to use this machine to remove water.You can set the time by yourself |

| 5. Frying machine |  | Model: TZ-1500 Power:36kw Voltage:380v,50hz,3 phase weight: 100kg size:1700*700*950mm Heating type: electrical capacity: 150L Capacity:150kg/batch (3 frames) Material: 304 stainless steel Fry time: 1.5-2 minutesDegree: 160-180°C |

| 6. Deoiling machine |  | Model: TZ-400 Capacity:300kg/h Dimension:1000*500*700mm Voltage:380v,50hz, 3 phase Power: 1.5kw Weight: 360kg Material: 304 stainless steel Function: after frying potato chips use this machine to remove the surface oil, then to the freezer machine. |

| 7. Seasoning machine |  | Model: TZ–800 Weight: 130kg Power: 1.5kw Capacity:300kg/h Voltage:380v,50hz, 3 phase Material: 304 stainless steel Simple design, cost saving, but does not affect production function and efficiency. |

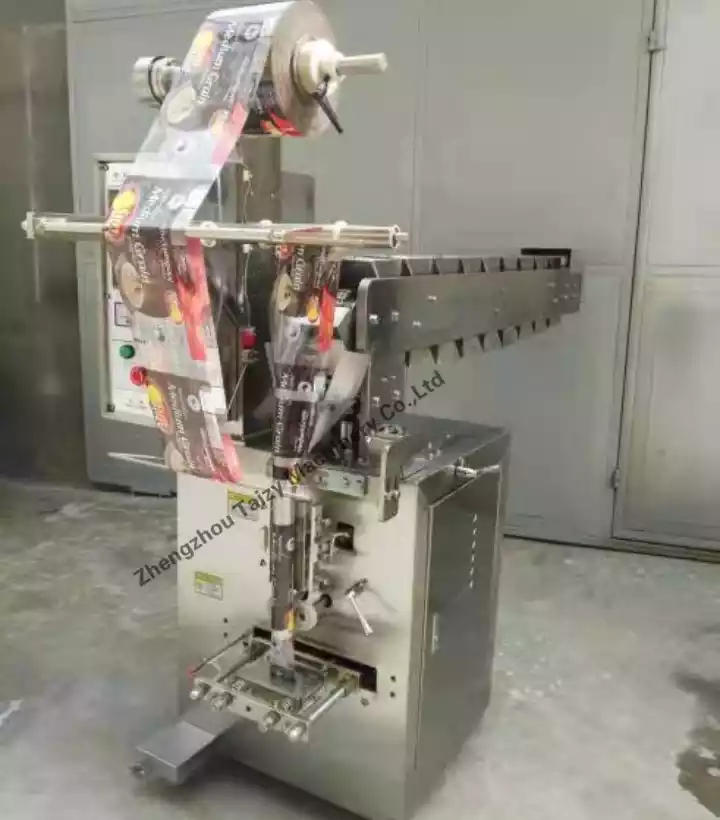

| 8. Potato chips packing machine |  | Model: TZ-450 packing machine Power:2.2kw Packing speed: 20-80bag/min Bag length: 30-300mm(adjustable) Roll film width: 40-450mm (need to replace the Former) Bag style: back seal, 3 side seal, 4 side seal Weight: 420kg Dimensions: 75011502100mm |

| 9. Frame for De-oil machine |  | Qty:2 sets Unit price :90usd Hight:300mm Diameter:500mm Weight:9 kg |

| 10. Frame for frying machine |  | Qty:2 sets Unit price:80usdSize:490*490*260mmWeight:5kg |

| 11. Heating tube |  | Qty: 6 pcs unit price: 50usdMaterial:304 stainless steel seamless pipe |

How long do potatoes need to be cleaned?

For potato cleaning time, there are two situations. First, if fresh potatoes are used for production, the cleaning time is generally 1-2 minutes. However, if you are using stock potatoes, the cleaning time will be longer, generally 5-6 minutes.

What is the thickness of the potato slices cut by the slicer?

The machine can cut potato chips between 2-9mm, but the thickness of potato chips in the potato production process is generally between 1-2mm. If the cut is too thin, it will cause the potato to be fragile during the frying process. If it is too thick, It will affect the taste, so the thickness of potato slices is very important.

In addition, the slices of potato chips need to be uniform, so that the heat can be better controlled during the frying stage.

Why blanch potatoes in potato chips production plant

Since potatoes are vegetables with a relatively high starch content, blanching can remove the starch on the surface of the potatoes, making the potato chips more crispy when they are fried, and avoiding too much starch which may cause the potato chips to be too soft. During the blanching process of potato chips, the machine needs to be preheated for 15-20 minutes at a temperature of 80℃-100℃, but the blanching time should not be too long, and the general time can be 1 minute.