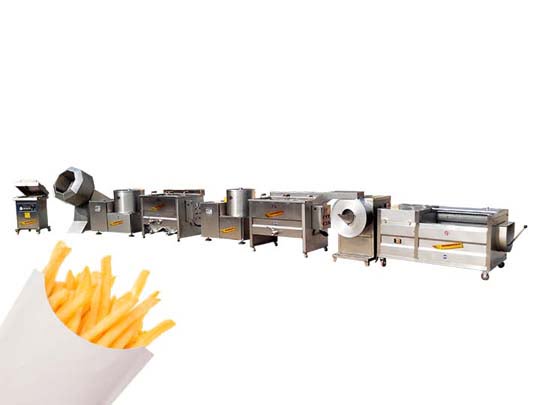

Small frozen French fries processing line, usually referred to as a general term for semi-automatic French fries making machines, contains all the functions of processing frozen French fries, and has the characteristics of compact structure, simple operation, and high work efficiency. The small-scale frozen fries processing plant is the best choice for many small-scale French fries processors.

What are the production advantages of the small frozen French fries processing plant?

Although, compared with the large-scale frozen fries plant, the small-scale fries processing line has a smaller output and the production efficiency is not high. However, many investors still choose small and semi-automatic French fries processing businesses. Why? There are three main reasons: the investment budget is not high, the production is more flexible, and the income is faster.

1. Lower investment budget

Large-scale frozen fries lines often require huge costs and budgets, including hiring workers, building factories, purchasing fries processing equipment, utilities, etc. The small-scale fries line does not require too many workers for general production, and the value of the equipment is small, usually without an independent factory building, and the investment cost is low.

2. Flexible production process

The production process of the small frozen fries processing plant is more flexible because it is a semi-automatic production process, and the hourly or daily output can be determined according to the production needs of customers. And because it is a semi-automatic production line match, it will not be restricted by the size and location of the factory.

3. Fast income and high profit

The main reason why the small frozen fries line is popular with fries processors is because of its high return on investment and large profits. Due to the low investment cost and high production efficiency, when the produced French fries are gradually sold in the market for about half a year, the small French fries processing business can realize cost-return and profitability.

Frozen french fries production line video

Composition of small frozen French fries processing plant

Brush-type washing and peeling machine

This electric washing and peeling equipment can realize fast pre-processing of potatoes. Its inner hard washing brush can not only remove the dirt of the potato but also can peel the potato skins efficiently. After washing, the clean potatoes will be discharged from the side door.

Fast slicing machine

This multi-functional potato slicer can make both potato strips and potato chips by replacing with different cutting blades. When cutting the potatoes, the labor should add them into the inlet one by one manually. It can also be used for slicing other root vegetables.

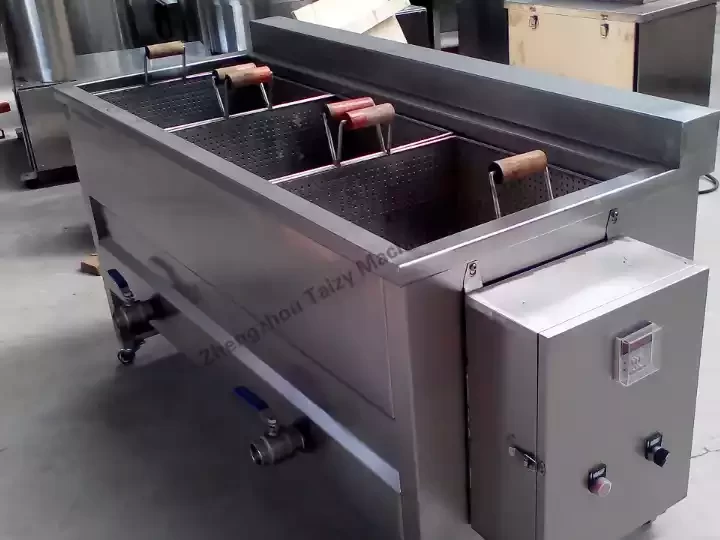

Blanching machine

The bleaching machine we used in this small frozen french fries processing plant is batch-type blanching equipment. And it can be customized with more than one chamber based on the customer’s needs. Except for the blanching function, it can also be used as a fryer machine.

Dewatering machine

Actually, the working principle of this dehydrator is like cloth washing machine dehydration, which quickly removes water droplets on the surface of blanched potato strips. The main function of rapid dewatering is to shorten the frying time of French fries and ensure that the frying process does not splash oil drops, thereby ensuring the safety of the frying process.

Frying machine

The fryer is a common equipment for processing fried foods such as French fries and potato chips and has the characteristics of high frying efficiency and large output. In addition, the frying time and temperature can be set and adjusted, which is very convenient to use.

Electric deoiling machine

In French fries processing, the working principles of dehydration and de-oiling are the same, so the machines used are also the same. The main purpose of degreasing fried French fries is to remove excess oil droplets on the surface of the fries, reduce the fat content of the fries, and ensure a crispy taste of the fries.

Quick freezing machine

The last step in making frozen French fries is to quickly freeze the fried French fries. Users can buy a commercial quick-freezer or use self-built cold storage to freeze French fries. The freezing temperature is approximately minus 45 degrees Celsius.

The production process of quick-frozen French fries

Firstly, use the brush-type washing and peeling machine to peel the potatoes. Second, use the fast-slicing machine to cut the peeled potatoes into strips. third, use the blanching machine to clean the french fries. forth, use the dewatering machine to dehydrate the potato sticks. Immediately after, use the continuous frying machine to de-oil the potato slices. After that, use the Quick freezing machine to de-grease french fries. Finally, our packing machine can make a wide variety of packages for frozen french fries.

Features of the small frozen french fries processing plant

The output of the semi-automatic frozen French fries processing line can be customized according to customer needs, usually, the output is between 50kg/h and 300kg/h.

The small frozen fries line designed and manufactured by our factory is very popular among users in North African countries, Middle East countries, and Southeast Asian countries.

Our factory has now successively exported a full set of fries processing equipment to more than 50 countries and regions, such as Saudi Arabia, Egypt, Nigeria, Ukraine, Philippines, Ghana, South Africa, Sri Lanka, Afghanistan, Turkey, Libya, Singapore, Australia, Canada, etc.

Some advantages of continuous frying machine

- The mesh belt transmission adopts step-less speed adjustment of frequency, and the frying time can be controlled.

- The frying equipment uses an automatic lifting system so that it is easy to clean.

- At the bottom, there is the waste discharge, it can automatically discharge the dregs.

- It uses the upper and lower double mesh belt to drive the french fries, which can avoid floating things。

- Our machine of this model has an oil circulation filtration system, which can continuously filter oil residue and extend the service life of edible oil.

- It is suitable for processing vegetables, cooked food, aquatic products, etc.

- The continuous frying machine adopts full 304 stainless steel, which can ensure the long-term stable operation of the equipment.

Have your frozen french fries ever been fried?

Generally, some professional manufacturers will recommend frying the fries before freezing them. This step plays a role in protecting the color and shape of the frozen french fries. Using our machine to fry French fries, the frying time is relatively short. The whole frying process lasts about 1-2 minutes.

Do we need to thaw frozen french fries before frying?

Frozen french fries do not need to be thawed before frying. The purpose of not defrosting is to make the fries more crispy and not easy to fall apart, instead of becoming soft at once after frying and cooling so as to affect the taste.

Details of frozen French fries production line

- Trimming: remove the bud eyes, mold, and other unfit parts from the raw material.

- Blanching: The cut chips need to be rinsed in water to avoid oxidation and browning when they are exposed to air. At the same time, blanching can wash away the surface of the free starch. This will prevent the starch from being incorporated into the fryer and affect the service life of the frying oil strips.

- Color protection: The temperature of color protection should be controlled between 80-100 degrees. To achieve the destruction of mold activity, the rinsing time should be 1-2 minutes.

- Dehydration: Dewatering has two main functions: shorten the frying time and increase the oil content of the finished product; ensure that the frying process does not splash oil drops, thus ensuring the safety of the frying process.

Our services

- Design and manufacture of equipment.

- Inspection and operation of all machines prior to dispatch.

- Engineers available for overseas machinery service.

- One-year warranty.

- 24-hour technical support via email.

- English software, user manual.