The potato chips processing line contains various machines for the production of potato chips. This production line is a 200kg/h potato chips production line and is a fully automatic production line, We also have other potato chips processing lines of 100-500kg/h, It is suitable for potato chip production factories that want to start a potato chip business.

How can I start a potato chips business?

Potato chips are favored by consumers, and the consumer market is also very broad. What do you need to do if you want to start a potato chips business? The first is to investigate the market. After there is demand in the market, and then starting the follow-up phase, the production raw materials will need prepared, including potatoes and machinery. The choice of the machine can be selected according to the size of the plant and the capital. This article introduces what machines will be in the 200kg/h potato chips processing line.

What machines are used to make potato chips?

There are many machines used to process potato chips, and it is a fully automated production machine.

Peeling machine: There are two functions for cleaning and peeling. The brush for potato cleaning and peeling is hard, so it can remove the surface layer of potatoes.

Potato slicing machine: Potato chip slicing machine is a machine that can slice potatoes. Just put the cleaned and peeled potatoes into the machine, and the machine will be processed into potato chips at the export of the machine.

Blanching machine: Blanching after slicing can remove excess starch in potatoes and keep the bright color of potatoes.

Dehydrator: After blanching, there will be a lot of water on the surface of potatoes, so they cannot be fried immediately. The dehydrator uses the principle of centrifugation for dehydration

Fryer: After the potato chips are dehydrated, they can be fried. There will be baffles for frying to prevent oil splashing.

De-oiling: After frying, there will be a lot of oil on the surface of the potato chips. In order to remove the grease quickly, I need to use a de-oiling machine to de-oil.

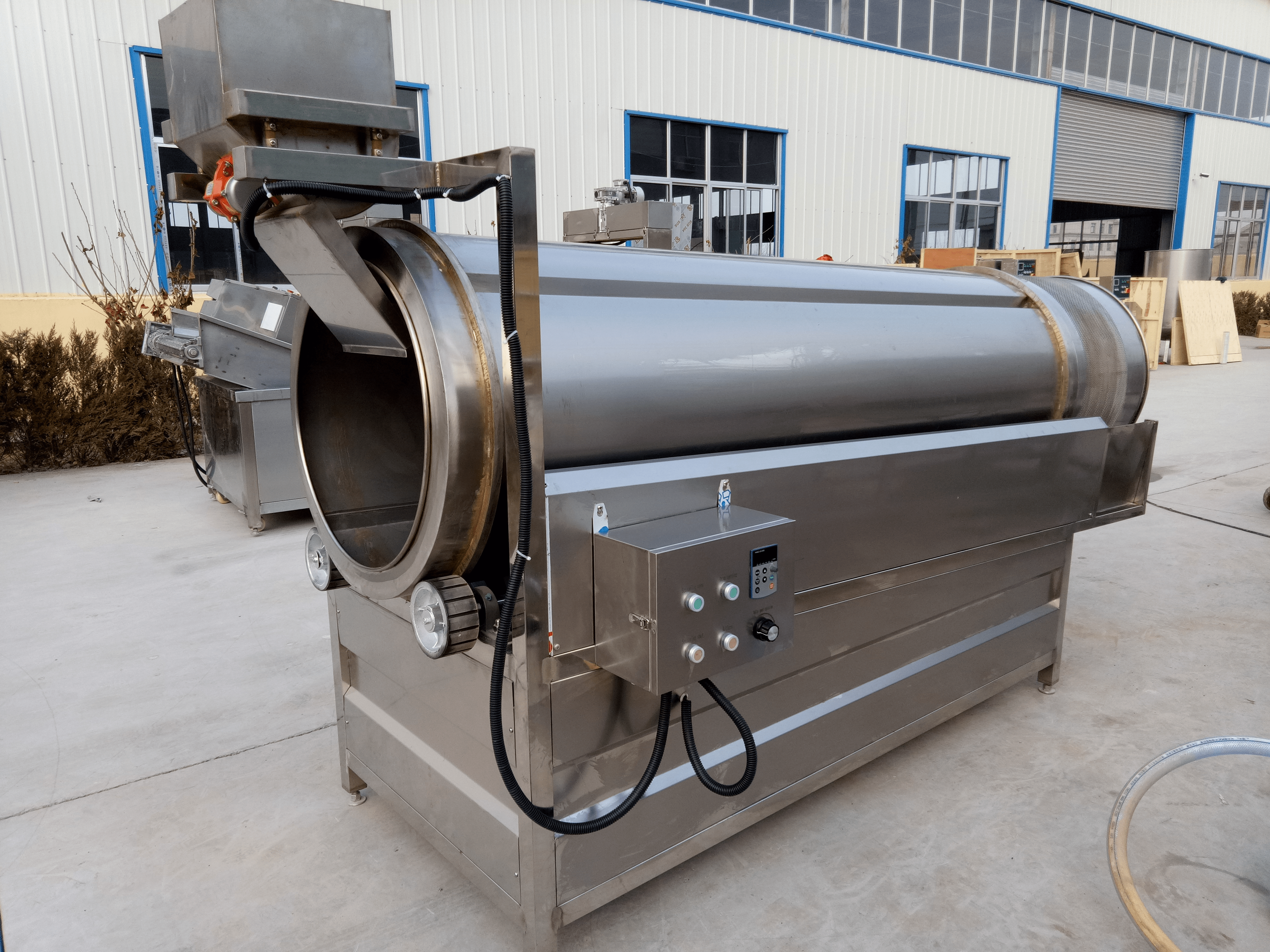

Cylindrical seasoning machine: The function of the seasoning machine is to season the potato chips. The machine rotates continuously to fill each potato chip with seasoning.

Packaging: Potato chips are relatively crisp and need to be vacuum-packed.

| Potato chip production line equipment (200kg/h output) | |||

| Equipment name | picture | power | Dimensions |

| 1. Cleaning and peeling machine |  | 1.5kw/380v/50Hz | 225000x850x800mm |

| 2、Potato slicer |  | 1.1kw/380v/50Hz | 950x800x950mm |

| 3. Hoist |  | 0.55kw/380v/50hz | 1500*800*1500 |

| 4、Round pot blanching machine |  | 60kw/380v/50Hz | 2200x1800x1600mm |

| 5.Dehydrator |  | 1.5kw/380v/50Hz | 1500x1500x1800mm |

| 6. Hoist |  | 0.75kw/380v/50hz | 1800*800*2000 |

| 7、Round pan frying machine |  | 60kw/380v/50Hz | 2200x1800x1600mm |

| 8.Dehydrator |  | 1.5kw/380v/50Hz | 1500x1500x1800mm |

| 9.Hoist |  | 0.75kw/380v/50hz | 1800*800*2000 |

| 10.Drum Mixer |  | 1.5kw/380/50hz | 3000*1000*1600mm |