The integrated type potato washing peeling and slicing machine is an efficient processing equipment integrating multiple functions, especially suitable for a small frozen French fries production line or agricultural products pre-processing scenario.

The equipment can complete the steps of washing, peeling, slicing, or cutting potatoes, sweet potatoes, carrots, and other root vegetables in one go, which greatly improves the processing efficiency and saves labor and time.

It is an indispensable and practical equipment for restaurant chains, food processing plants, cooperatives, and other units.

Advantageous features of the machine

- Multi-functional integrated design: integrating cleaning, peeling, slicing and shredding, one machine is multi-purpose, adapting to the processing needs of a variety of root and stem vegetables.

- High-efficiency processing capacity: stable operation of the equipment, fast processing speed, suitable for small batch or continuous production, significantly improving production efficiency.

- Saving labor cost: high degree of automation, easy to operate, only a small amount of manual assistance, you can complete the whole set of pre-treatment process.

- Uniform and beautiful finished products: the effect of slicing and shredding is neat and uniform, which is conducive to subsequent processing or packaging of finished products.

- Compact structure, space-saving: small footprint, suitable for kitchens, food factories and other limited space use scenarios.

- Hygienic and easy to clean: the whole machine is made of food-grade stainless steel, corrosion-resistant, wear-resistant, easy to clean and maintain, in line with the hygienic standards of food processing.

Machine application scenarios

- Used in the pre-processing procedures such as cleaning, peeling, cutting, etc. in the pre-processing of French fries or potato chips.

- Realize the rapid processing of potatoes and other root vegetables, convenient for subsequent distribution or packaging.

- Enhance the speed of vegetable production and ensure the uniformity and standardization of vegetables.

- Used for preliminary processing of potatoes, carrots, sweet potatoes, etc. to facilitate sales or deep processing.

- As the front section equipment of the assembly line, it is used with other washing, sterilizing and drying equipment.

Classifications of the potato washer and peeler machine

The automatic cleaning and peeling machine has a large market demand. Because of its compact structure and high work efficiency, it is very suitable for frozen fries and potato chips production lines with an output of 50kg/h to 150kg/h.

In addition, according to different customer needs, we have designed this device uniquely. And designed two common types of customers.

Washing and peeling only type

The electric washing machine has both potato cleaning and peeling functions and is very suitable for semi-automatic French fries and potato chips processing lines with small capacities.

Except for the internal structure of the motor and the cleaning bucket, the machine is made of 304 stainless steel, which is very durable.

The cleaning bucket of this automatic potato cleaning and peeling machine uses advanced silicon carbide material inside, which is very resistant to wear.

In addition, the internal friction surface is optimally designed according to different potato types, which can achieve the effect of rapid cleaning and peeling to the greatest extent.

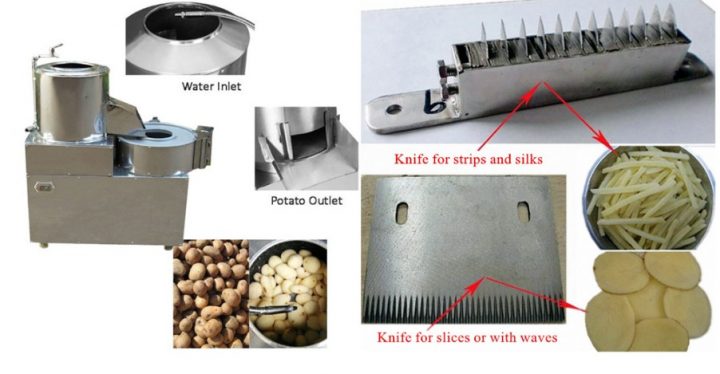

Integrated washing peeling and slicing type

This multifunctional potato washing peeling and slicing machine is very suitable for small-yield but highly automated fries and potato chips production lines and various restaurants.

It adds a high-speed cutting knife to the former device, which can quickly cut the cleaned and peeled potatoes into strips and chips. Moreover, the size of the potato cut can be adjusted by adjusting the cutter gap.

We also have specialized washing machines for potatoes and other vegetables if you need them. Click for details: Automatic Potato Washing and Cleaning Machine | Potato Washer.

Potato washing peeling and slicing machine using precautions

- Before starting the machine, the user should carefully check the machine for any debris in the washing bucket.

- When the potato washer is working, it is strictly forbidden to put your hand into the cleaning bucket.

- Before cleaning and disassembling the machine, first, disconnect the power supply to stop the machine.

- To ensure the safety of the production process, the machine must be reliably grounded.

- The bearings of the automatic potato washing peeling and slicing machine should be changed every three months.

- During the use of the machine, please do not press the switch with wet hands.

Integrated potato washing peeling and slicing machine parameters

| Model | Weight(kg) | Power(kw) | Capacity(kg/h) | Dimension(mm) |

| TZ200 | 120 | 1.1 | 200 | 750*500*1100 |

| TZ400 | 140 | 1.5 | 400 | 950*700*1150 |

Whether it’s used in a small processing plant or a central kitchen, this potato washing peeling and slicing machine can help you improve efficiency and save labor costs. We also provide customized service. Welcome to contact us for more product information and a quotation!