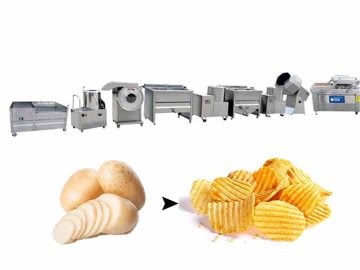

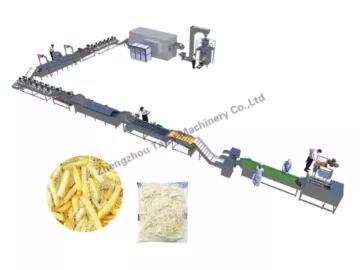

在大容量薯片生产线和冷冻薯条加工线中,切片后的薯片和薯条需要经过漂烫过程才能进行油炸和调味。为什么?漂烫土豆有助于去除残留的土豆皮,保护颜色并防止氧化。

什么是土豆漂烫?

通常,在全自动薯片和薯条加工线中使用连续漂烫机,可以在切片后的薯片上进行约3-5分钟的连续漂烫。

在半自动加工厂中,漂烫机需要人工操作,并且漂烫工作分批进行。每批大约需要3分钟。土豆漂烫温度在80℃-100℃之间,可以根据不同的土豆品种进行调整。

土豆焯水时间越长越好吗?

马铃薯漂烫虽然容易操作,但对漂烫时间有特殊要求。如果土豆漂白时间太短、温度太低,就会刺激土豆中存在的酶的活性,从而导致土豆的风味、色泽和质地丧失。

如果漂烫过多,会使马铃薯品质下降,影响其风味、色泽、维生素和矿物质含量,并增加生产成本。

土豆焯水有什么好处?

1、焯水可以帮助深层清洁土豆表面。它可以杀死马铃薯表面的细菌、霉菌和其他生物。

2.马铃薯焯水会阻止酶的作用。当蔬菜成熟时,酶将继续发挥作用,直到蔬菜形成可行的种子繁殖。焯水可以杀死土豆中的酶,从而保持土豆的风味、颜色和质地。还可以延长土豆的保存期。焯水后,土豆即使接触氧气也不会变黑。

3、焯水可以使土豆表面的淀粉糊化。在油炸过程中,焯过水的土豆会在表层迅速形成一层糊化淀粉,从而限制了油脂的吸收,可以降低薯片或薯条的含油量,让口感更好。

4、焯水可以降低薯条中丙烯酰胺的含量。热烫可以提取马铃薯中的还原糖和氨基酸——天冬酰胺,并降低炸薯条中丙烯酰胺的含量。油炸后,土豆可以形成均匀的颜色。

总而言之,我们可以得出结论,在薯条和薯片加工过程中,漂烫是必不可少的。