Great news! Our customized potato chips manufacturing line for a Belgian client has successfully passed inspection and been loaded for shipment. This project was comprehensively planned around the client’s existing production scale and market expansion needs, aiming to enable stable mass production and standardized packaging of their potato chip products.

Client background and procurement requirements

The client is a medium-sized food enterprise specializing in the production and sales of potato-based snack foods. Their products primarily target local supermarket chains and community retail channels, supported by a stable local sales network.

The client sought to establish a compact, fully integrated potato chips manufacturing line enabling continuous operations from raw material handling to finished product packaging, while balancing space constraints and investment budget control.

During preliminary discussions, the client emphasized the following key aspects:

- Whether the production process is complete and seamlessly integrated.

- Flexibility in adjusting finished product specifications (e.g., 25g, 50g small packs).

- Compliance of equipment with EU food processing standards.

- Availability of remote technical support post-installation.

Based on the client’s specific requirements, our factory developed a comprehensive potato chip processing solution.

Composition of this potato chips manufacturing line

This shipment comprises a complete customized potato chip processing line covering key production stages, including:

- Potato cutting machine

- Blanching equipment

- Dehydration machine

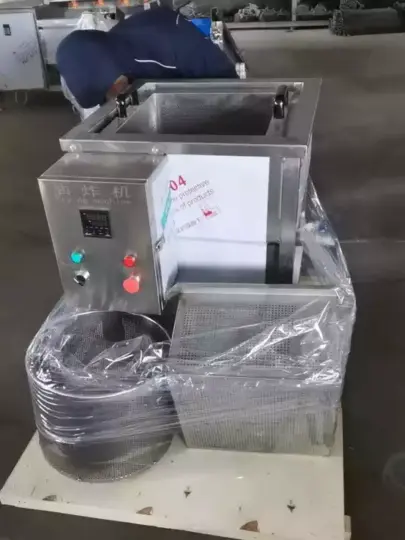

- Frying equipment

- Oil-removal equipment

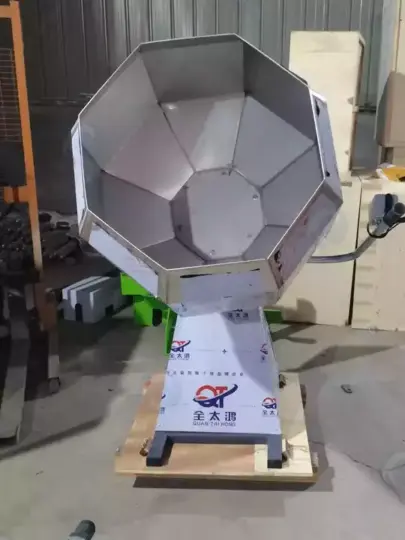

- Automatic seasoning machine

- Automatic packaging machine (with date printing functionality)

Additionally, bag formers and specialized material hoppers that match the client’s product specifications were included as supporting accessories to ensure the production line is ready for immediate installation and commissioning upon arrival.

The entire equipment set underwent integrated trial operation testing before shipment, ensuring seamless process integration and stable operation.

We will continue to provide remote installation guidance and technical support to assist customers in completing commissioning and production startup, ensuring the smooth operation of the production line.