This frying line for potato chips is a device for producing crispy potato chips, and the entire production line is fully automated. The main production process of the French fries line is potato cleaning and peeling, potato slicing, blanching, dehydration, frying, seasoning, and packaging. Each process is produced by professional machines. The output of this production line is 1000kg/h, we have production lines with different outputs.

Taizy company’s different frying line introduction

Our company is a factory that exports French fries and chips. The company has a large-volume automatic production line and a small-volume semi-automatic production line. The process for producing potato fries and chips is basically the same. The main difference between semi-automatic production and fully automatic production is that the output is different, and the methods of feeding and discharging are different. The semi-automatic production line needs to manually put the raw materials into the machine, and the discharging is generally manually assisted. The fully automatic production line generally uses a hoist to connect the machines, which saves more labor and improves overall production efficiency.

Nutritional value of potatoes

The nutrients contained in potatoes are very comprehensive. In addition to high carbohydrates, there are also various nutrients such as protein, vitamin C, vitamin BI, carotene, etc. The protein of potatoes is special, and the calories per 100 grams of potatoes are only equivalent to 1/2 of eggs and milk of the same quality. Potatoes can be used as both vegetables and staple food. The biggest advantage of potatoes is that they can still maintain their original flavor after being processed into food.

Brush washing and peeling machine

The potato cleaning and peeling machine is a machine that combines two functions. The main working principle is to use the friction between the brushes of the machine to clean and peel the potatoes without damaging the potatoes. The machine also has two ways: forward and reverse. The cleaned potatoes are removed by reverse rotation of the brush.

Potato cutter machine

This machine is a machine that can cut potatoes into slices. It can be seen from the above parameters that the maximum output of each machine is 800kg/h. We are equipped with two slicers on this production line. To ensure an adequate supply of potato chips.

Capacity:600-800kg/h

Dimension :950*800*950mm

Voltage : 380V/220V

power: 1.1kw

Weight: 110kg

The machine is characterized by high efficiency, simple appearance, simple structure, and convenient operation.

Fast cutting speed, smooth cutting surface, no damage,

Chip size is adjustable from 1-10mm.

Blanching equipment of frying line for potato chips

The blanching machine is ideal equipment in the blanching process of vegetables and fruits’ color-protecting, it’s necessary blanching equipment in preprocessing of quick-freeze, dehydration, freeze-drying. This blanching machine is with characteristics of fast blancher, inhibition of enzyme and color-protecting, timely dehydration and cooling, so as to keep the original nature colors of vegetables and fruits.

This blanching machine will blanch the food materials, at the same time, the materials will also be cleaned by turning water. The blanching temperature is controlled by a solenoid valve, thermoelement, and temperature-controlled meter; the blanching time will be controlled by a frequency converter, the conveying belt speed can be adjusted. The temperature controller will make the water temperature in the water channel keep the required temperature, the maximum temperature can be 100℃.

The fryer of frying line for potato chips

This fryer can operate continuously. The machine adopts the method of conveyor belt, which can realize automatic feeding and automatic discharging, and the oil temperature can be automatically controlled, and the temperature can be adjusted arbitrarily from 0 to 300 degrees. In addition, the machine also has a smoke exhaust function to ensure a good green tea environment in the production factory.

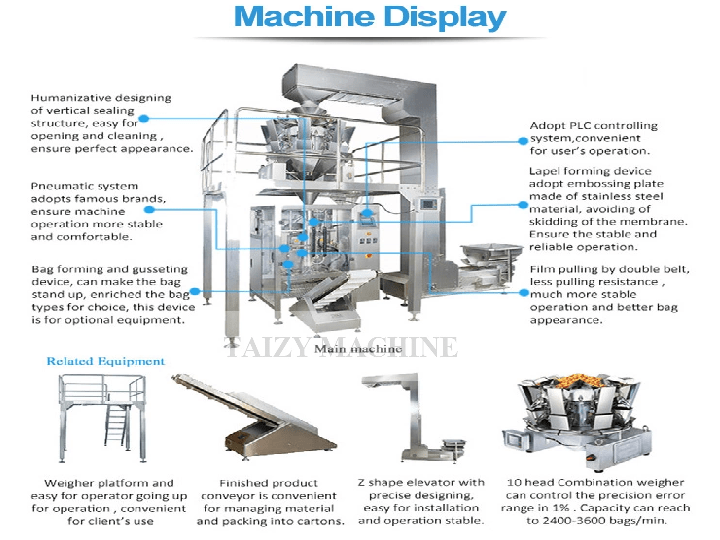

Potato chips packing Machine

The packaging machine can be packaged after weighing, and each individual package has the same weight, which is convenient for industrial production. The packaging machine system can realize the functions of filling, bag making, metering, etc. In addition, the machine can perform the functions of printing data and slitting bags.

Purchasing a fried potato chip production line benefits analysis

The raw materials of the fried potato chips production line are relatively simple, the output of potatoes is high, and the price is cheap. In addition, the functions of the fried potato chips production line can be diversified. After a small modification, the machine can be used for the production of potato chips production lines. The fryer can also produce a variety of products, such as fried banana chips, fried peanuts. Wait.