The 300kg/h potato chips processing machine has the advantages of high output, labor-saving, and high product quality. The potato chips processing line is fully equipped. We also have a production line of 50kg/h-1 ton/hour. Can be selected according to production needs.

Potato cleaning machine

The potato chip cleaning machine is a device that can automatically clean potatoes. The potato cleaning machine can also remove potato skins, reducing manual workload. The working principle of potato cleaning machine peeling is to use a hard brush to peel. This method can reduce the waste of potatoes.

Advantages of fryer in potato chips processing machine

This 300kg/h French fries production line uses a continuous fryer, which has a large output and high efficiency. It is generally used in a frying production line and can realize fully automated production.

Dehydration and deoiling time of potato in potato chip production machine

After the potato chips are blanched, the surface will have a lot of water, and the surface of the fried potato chips will have a lot of oil. In order to ensure the taste of the potato chips during the processing, the potato chips will be dehydrated and deoiled during the production process. How long does it take for dehydration and deoiling? It usually takes two minutes. Dehydration and deoiling are produced by the principle of centrifugation.

Why are potato chips packets filled with nitrogen?

Potato chips are very thin, and they are also very crisp. Nitrogen filling the potato chip packaging can protect the potato chips, and it is also convenient for transportation and sales. In addition, nitrogen is a kind of gas in the air, so it is easy to obtain. Therefore, the cost will not increase much, and the nitrogen will not affect the food, nor will it affect the release into the air. Therefore, it is the best choice to pour nitrogen into the potato chip packaging.

What information do we need to know when customer buy potato chip processing machines?

1. You want to make potato chips or potato chips?

2. The output requirements of finished products per hour (we have a production line of 50kg/h-1 ton/hour)

3. Are potatoes purchased in the market or grown by you?

3. Oil electric heating and gas heating for the blanching machine and frying machine.

4. Does the customer have a plant? What is the area and in which country the machine will be used?

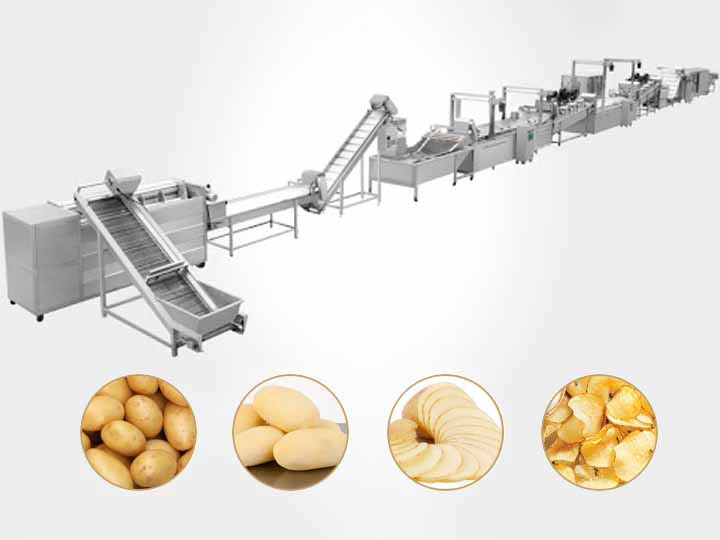

Potato chips processing machine show

Hoist→Washing and peeling machine → Picking line → Hoist → Slicer machine → Washing machine → Blanching machine → Vibration dewater machine → Hoist → Frying machine → Vibration deoil machine → air cooling machine → Hoist → Seasoning machine → Packing machine

Potato chip processing machine parameters

Potato chips processing machine Item | Specifications |

1. Water bucket hoist  | Model: TZ-170 Power:5kw Voltage:380v/50Hz Size:40009001600mm Material: 304 stainless steel Function: pre-wash potato and clean mud |

2. Wash machine  | Model: TZ-2000 Power:4.37kw Voltage:380v/50Hz Size:34009001400mm Weight:450kg Capacity:2000kg/h Material:304 Stainless steel After being lifted, the potatoes enter the pre-washing machine, and the soil on the surface of the potatoes is cleaned by a hair roller and spraying, and then enters the next step. |

3.Hoist | Model:TZ-100 Power:0.55kw Voltage:380v/50Hz Size :18008001500mm Weight:160kg Material:304 Stainless steel This machine can adjust the speed manually, save time and energy. |

4. Wash and peel machine | Model: TZ-2000 Power:5.87 kw Voltage:380v/50Hz Size:34009001400mm Weight:450kg Capacity:2400kg/h Material:304 Stainless steel The pre-washed potatoes go through the elevator into the peeling machine and are thoroughly peeled by the emery roller and wool roller. details:Hair rollers 5pcs,emery rollers 4pcs; a circulating filter water tank at the bottom can effectively save water resources; the potatoes are automatically discharged through the screw drive; the peeling time can be adjusted; The equipment is made of 304 stainless steel with a thickness of 3MM. The frame is made of 304 stainless steel of 50 *50 * 4MM. Bearings are 316 stainless steel; The equipment has adjustable feet and a removable universal wheel for easy transportation. |

5. Picking conveyor | Model: TZ-200 Size: 4000800950mm Power:0.75kw Material:304 Stainless steel Purpose: picking the broken potatoes details: PVC high-quality food-grade conveyor belt, the motor is a speed-adjustable motor, the conveyor belt speed is adjustable, FL206 stainless steel bearing seat, the bottom angle material is 304 stainless steel, and the height is adjustable. |

6. Water bucket hoist  | Model: TZ-170 Power:2.25kw Voltage:380v/50Hz Size:300080001600mm Material: 304 stainless steel |

7. potato chips Cutter | Model: TZ-600 Size:10006001500mm Capacity:1500kg/h Material: the blade is made of high-speed stainless tool steel, the turntable is made of high-quality aluminum-magnesium alloy, and the rest is made of 304 stainless steel, thickness 2mm Knife:2mm chips or according client needs, if want do different size, buy an extra set of blade |

8. Bubble washing machine | Model: TZ-1000 Power:6.6kw Voltage:380v/50Hz Weight:600kg Capacity:2000kg/h Belt width:800mm Size:500012001300mm Material: 304 stainless steel details: The equipment is made of 304 stainless steel with a thickness of 2MM. The frame is made of 304 stainless steel of 60 * 40 * 2MM. The equipment has adjustable feet and a removable universal wheel for easy transportation. Through the bubble tumbling cleaning, the potato strips are in a tumbling state, and the starch on the surface of the potato strips is fully washed, and it is equipped with a secondary spray cleaning function with water. |

9. blanching machine | Model: TZ-700 weight: 900kg size:600012002200mm Capacity:500kg/h temperature: 95 degree Belt width:800mm Material:304 stainless steel Heating type: electric Power: 220kw details: The equipment is made of 304 stainless steel with a thickness of 4MM. The frame is made of 304 stainless steel of 50 * 50 * 2MM. The equipment has adjustable feet and a removable universal wheel for easy transportation. It stops the enzyme activity in the potato strips, maintains the original fresh color of the potato strips, improves the flexibility of the cells, and facilitates water evaporation. The thickness of the insulation layer is 70mm. |

10. Air cooling machine | Model: TZ-300 Size:600012001600mm Voltage: 380v Power:15kw Fans:16 pcs Weight:350kg Belt width:800mm Material:304 stainless steel details: The air inlet of the fan adopts a dense hole filter system, the height of the fan is adjustable, and the high-quality stainless steel bearing. The working principle is to transfer the blanched potato strips through the mesh belt and turn it over many times to realize the multi-faceted wind and uniformity of the material. The high-pressure wind of the blower cools the food and removes the moisture on the surface of the potato strips. |

11.Hoist | Model:TZ-140 Size:200015001350mm Voltage: 380v,50hz Power:0.75kw Material :304 stainless steel |

12. fryer machine | Model: TZ-700 weight: 900kg size:800014002200mm Capacity:500kg/h Belt width:800mm Material:304 stainless steel Heating type: electric Oil capacity:2100L Power: 160kw details: The pure oil frying process is equipped with a dynamic filter system and a circulation device. It can automatically filter and discharge the slag during the working process to ensure the quality of the frying oil. It is equipped with an automatic lifting function, which is conducive to cleaning and sanitation. With variable frequency speed regulation, the oil temperature can be adjusted from room temperature to 300 degrees. Fryer price includes oil tank storage price. |

13. Oil tank storage | Oil pump motor power: 1.5KW/ 380V/50Hz size: 140013001850mm Material:304 stainless steel, the oil storage tank is equipped with heating function, with a filter, and the thickness is 3mm, with an insulation layer. |

14. oil filter | Coarse filter tank diameter: 300mm Fine filter tank size: 450mm Circulating pump:1.5kw details: When the equipment is working, the oil in the frying machine first enters the coarse filter under the action of the internal and external pressure difference, and then enters the fine filter through the circulating pump. Under the action of the fine filter paper, the ultrafine particles in the oil are removed. The sundries are filtered out, and the oil flowing from the oil outlet is the oil that meets the requirements. It is connected to the fryer through the pipeline to complete the dynamic filtering, thereby completing the entire filtering process. |

15. Fuel tank | The fuel tank is equipped with a heating device. The oil that needs to be added is heated to a certain temperature through the heating tube and then sent to the inside of the fryer through a circulating pump to achieve the purpose of adding oil. |

16. De-oil machine | Model: TZ-900 Size :180010001300mm De-oil time:2 mins Power:0.25kw Voltage:380v Material:304 stainless steel details: The equipment is made of 304 stainless steel with a thickness of 4MM. The frame is made of 304 stainless steel of 100 * 50 * 5MM. The equipment has adjustable feet and a removable universal wheel fo easy transportation. |

17. Cooling machine | Modei:TZ-300 Size:500011001600mm Voltage: 380v Fans:14pcs Power:10.5kw Belt width:800mm Material :304 stainless steel The height of the fan is adjustable, and the bottom of the air trunk line is equipped with an oil pan |

18.Hoist | Model:TZ-140 Size:20008001600mm Voltage: 380v,50hz Power:0.75kw Material :304 stainless steel |

19. seasoning machine | Model: TZ-2400 Size:240010001600mm Voltage: 380v,50hz Power:1.5kw details: The equipment is made of 304 stainless steel with a thickness of 2MM. The frame is made of 304 stainless steel of 50 * 50 * 2MM, bearings are 316 stainless steel. The equipment has adjustable feet and a removable universal wheel for easy transportation. |

20. packing conveyor | A.Feed conveyor Delivery value:3-6m³/h Voltage:380v Weight:500kg B.TZ-720 Vertical Automatic Packaging Machine Bag length:100-400mm(L) Bag width:180-350mm(W) Max width of roll film:720mm Packing speed:5-50bags/min Measuring range:6000ml(Max) Air consumption:0.65Mpa Gas consumption:0.4m³/min Voltage:220VAC/50HZ Power:5kw Dimension:(L)1780(W)1350(H)1950mm Notes: Includes 1pcs bag former C.10 Buckets Multi-Head Weigher Machine Maximum weighing:1000g Single weighing range:10-1000 g Weighing accuracy:±0.3~1.5 g Weighing capacity: Max 3000cc Weighing speed: Max 3000cc Control unit:8.4 inch key screen D.Platform Non-slip countertop, guardrail around, practical and safe. E.Finished product conveyor |

video of Potato Chips Line