The 400kg/h potato chips manufacturing plant was originally a fully automatic machine for the production of potato chips. The production first included all production tools from potato cleaning to potato chip packaging. The production line can produce potatoes in an efficient, clean, and hygienic manner. It is a very good choice for potato chips and fries production.

Why do potatoes need to be cleaned twice?

Potatoes grow in potatoes. There is a lot of dirt on the outer skin. The skin needs to be washed first and then peeled. The first cleaning is mostly to remove the dirt on the surface. Then, it needs to be sliced. After slicing, Then use a bubble cleaner for cleaning. The second cleaning is to reduce the starch content in the potatoes. The potato chips we eat are very crisp. This is the result of repeated cleaning. In addition, the purpose of blanching is to reduce the starch content. , At the same time, make the color of potato chips brighter. Cleaning is a part of the potato chips manufacturing plant

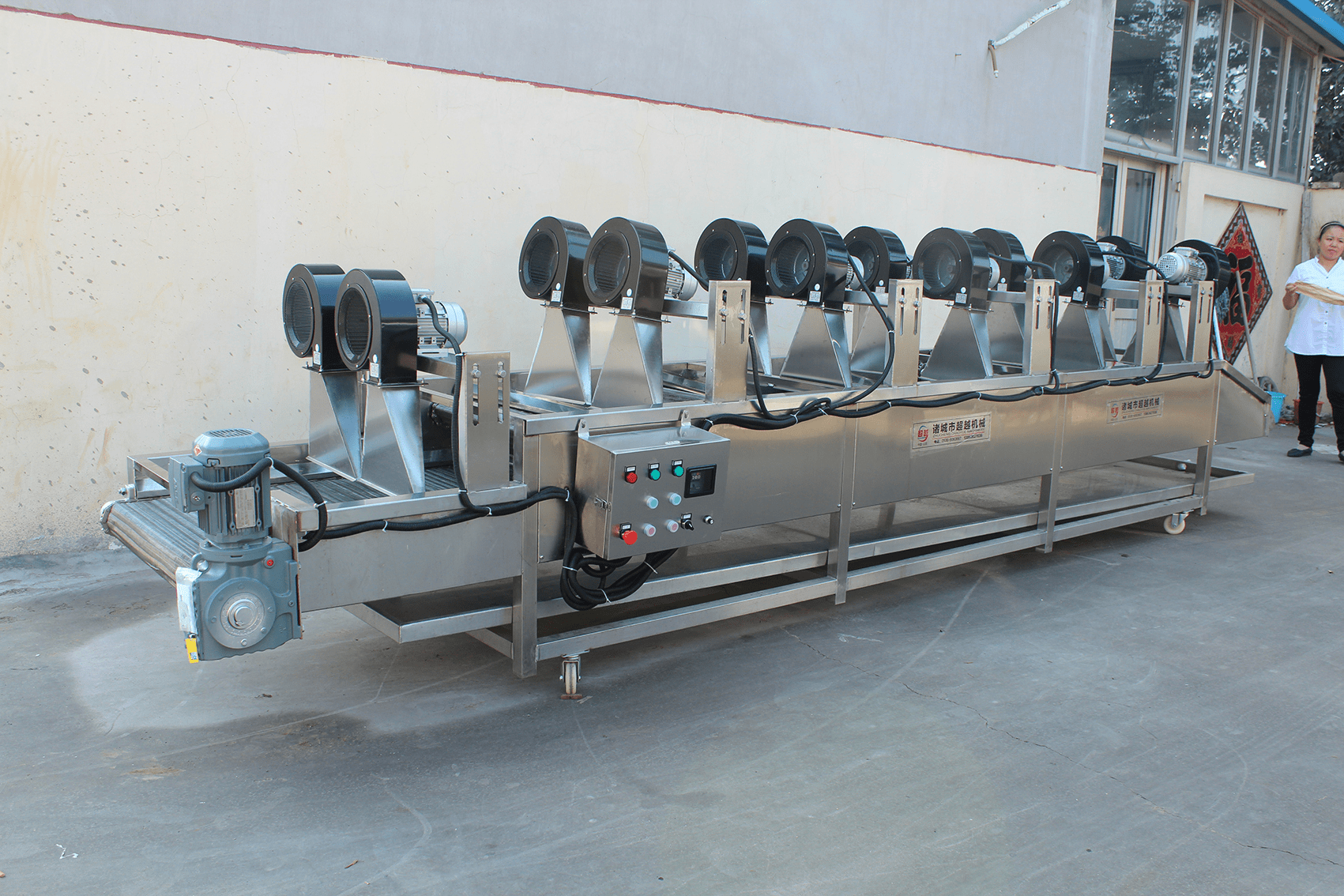

The important role of potato chips air drying

After the potato slices are blanched, there will be water on the surface of the potatoes. The water must be removed before frying. It will take a long time to dry naturally. However, using an air dryer and air drying will save time. Frying after air-drying will not cause the splashing of hot oil. It will be more secure.

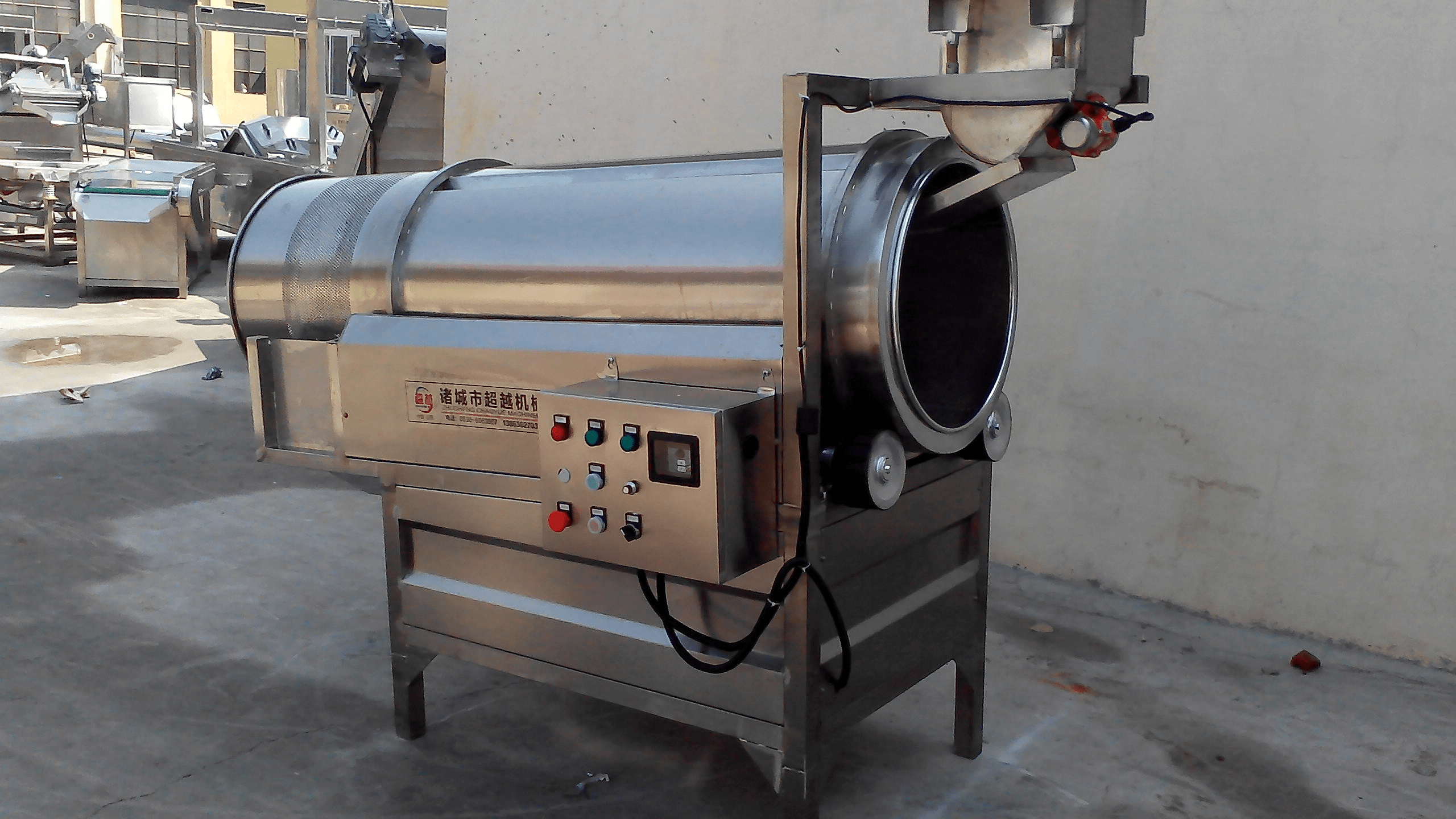

How to make potato chips of various flavors?

There are many flavors of potato chips, how to make potato chips of various flavors? In fact, in the production process of potato chips, the steps before seasoning are the same. To make potato chips with different flavors, seasoning is done with a seasoning machine. Seasoning needs to be prepared during production, and then the seasoning machine can proceed. Sprinkle the seasoning evenly on the potato chips.

Parameters of 400kg/h potato chips manufacturing plant

| Product name and picture | Details |

1. Water bucket sinking stone elevator | Power:5kw Product size: 4000*900*1600mm Function: The raw potatoes pass-through this elevator and enter the pre-washing machine for cleaning and sludge removal. |

2. Hair roller pre-washing machine | power: 4.37kw. size:3400*900*1400mm Function: After being lifted, the potatoes enter the pre-washing machine, and the soil on the surface of the potatoes is cleaned by hair rolling and spraying and then enters the next step. |

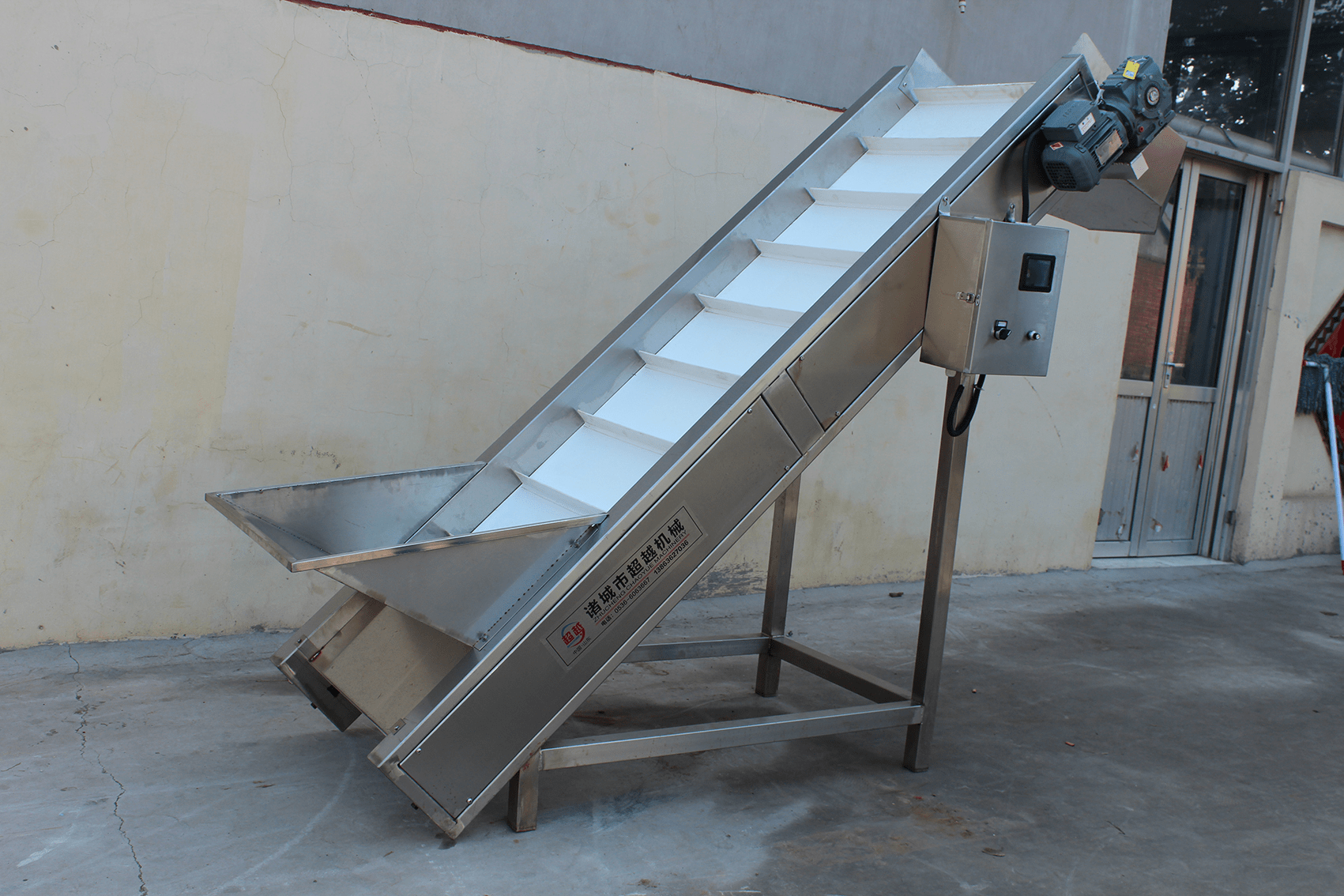

3. Hoist | power: 0.75kw size:1800*800*1500mm Function: The washed potatoes enter the peeling machine through this elevator. |

4. Hair roller peeling machine | power:5.87kw size: 3400*900*1400mm Function: The pre-washed potatoes enter the peeling machine through the elevator, and are thoroughly peeled by the emery roller and wool roller. The number of hair rollers used is 5, the number of emery rollers is 4, and the bottom is equipped with a circulating filter water tank, which can effectively save water resources. The potatoes are automatically discharged through the screw drive, and the peeling time can be adjusted |

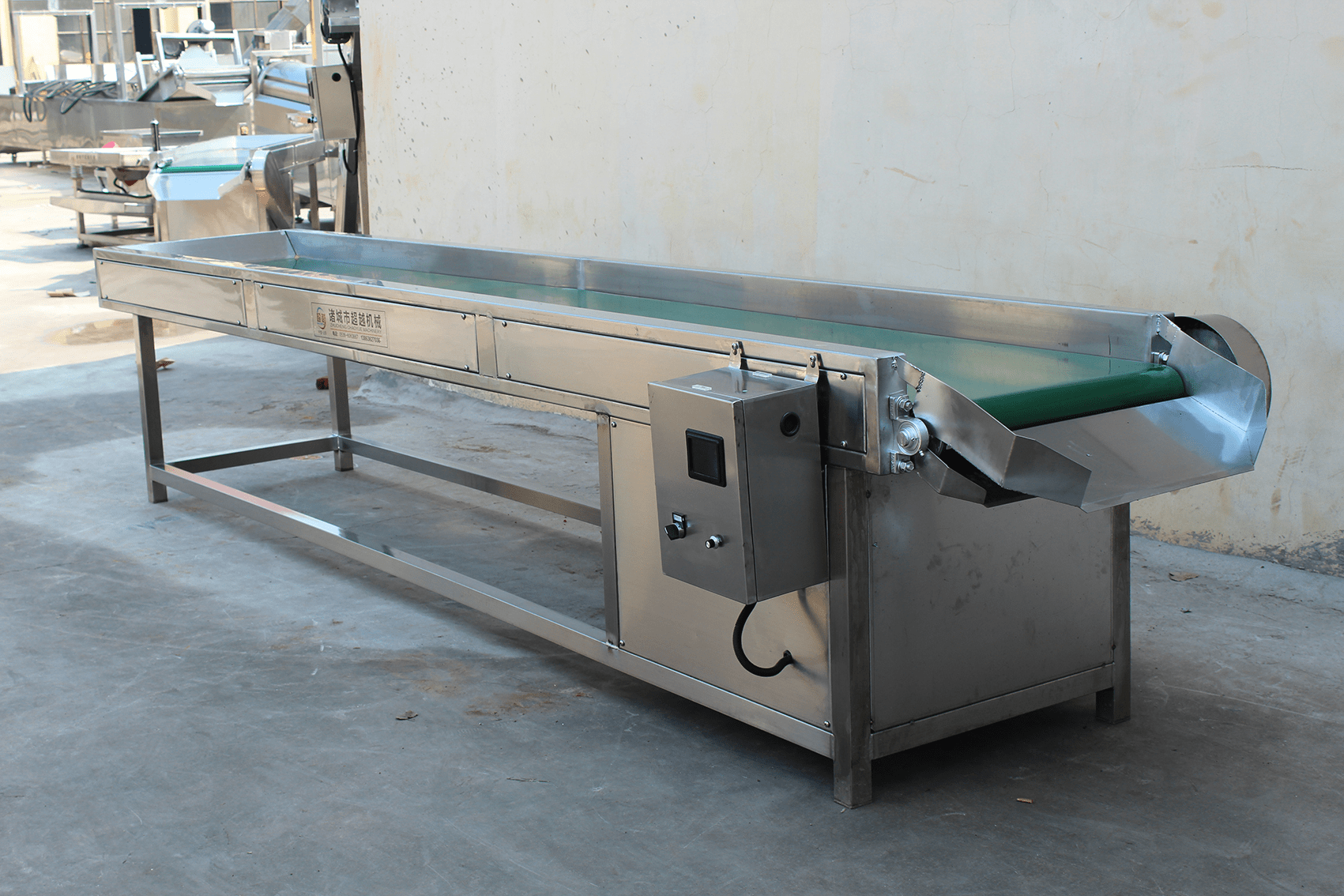

5. Picking line | power: 0.75KW/380V/50Hz size: 4000*800*950mm Function: After the potatoes are peeled off, they enter this equipment, and then manually pick them to see if there are broken spots or unqualified potatoes, or unwashed skins, and do some treatment. |

6. Cleaning the elevator | power:2.25kw size:3000*800*1600mm |

7. Efficient slicer | size:1000*600*1500mm output:1500kg/h Function: Qualified potatoes enter the potato chip machine automatically through the picking line, and the potato chip machine continuously completes the cutting work. |

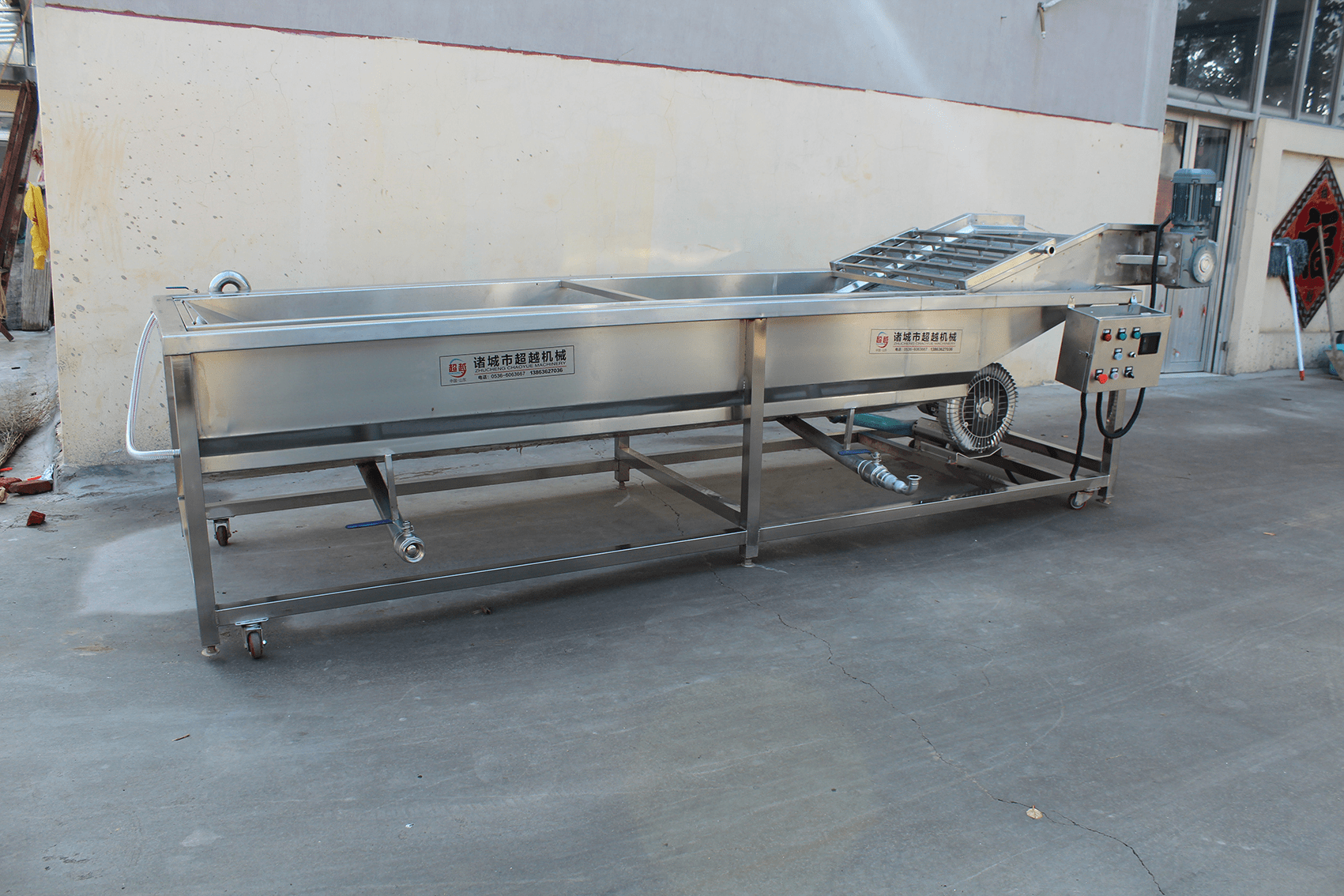

8. Bubble rinsing machine | power:6.6KW/ 380V/50Hz size:5000x1200x1300mm Function: The qualified French fries from the decontamination machine directly fall into the rinsing machine, and the potato strips are tumbling through the bubble and wave washing, so that the starch on the surface of the potato strips is fully washed, and it is equipped with a secondary spray cleaning function with water. |

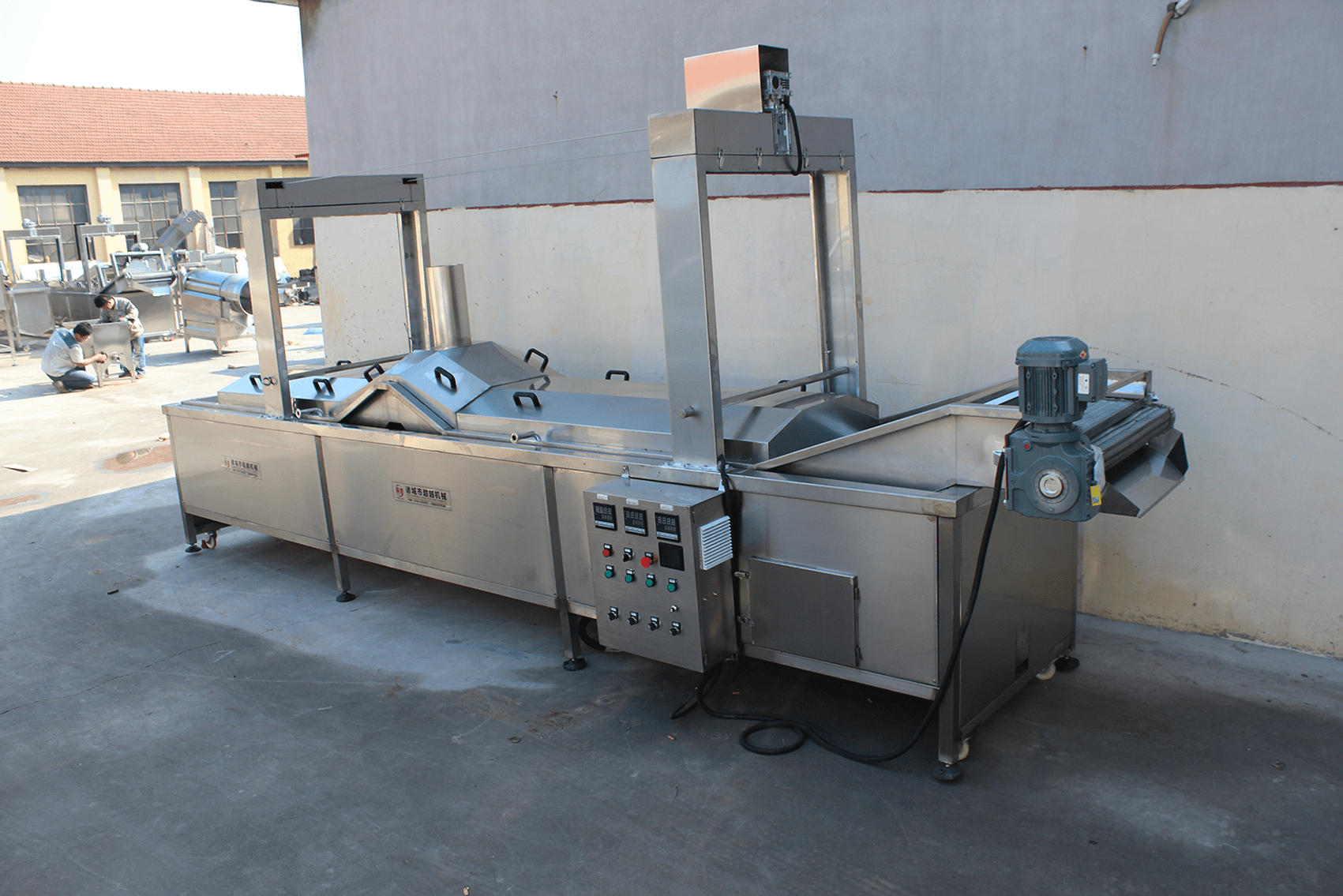

9. Blanching machine | power:180KW/380V/50Hz size:6000x1200x2200mm Function: After rinsing, the French fries enter the blanching machine. This machine adopts an electric heating method, the water temperature is controllable, the material used is high-quality 304 stainless steel, the bearing seat is 304 stainless steel bearing seat, the mesh belt width is 800mm, the mesh is 3mm, and it passes through this machine. It stops the enzyme activity in the potato strips, maintains the original fresh color of the potato strips, improves the flexibility of the cells, and is conducive to water evaporation. The mesh belt motor is a speed-regulating motor, and the thickness of the insulation layer is 70mm, which effectively prevents heat loss. |

10. Airline | power:15kw/ 380V/50Hz size:6000x1200x1600mm Function: The blanched potato strips are transported in through the mesh belt and turned over many times to realize the multi-faceted wind and uniformity of the material. The high-pressure wind of the blower cools the food and blows the moisture on the surface of the potato strips to dryness. |

11. Stainless steel hoist | power:0.75KW/ 380V/50Hz size:2000x1500x1350mm |

12. Fryer | power:2.2KW size:8000x1400x2200mm Function: The oil temperature is adjustable from room temperature to 300 degrees |

13. Oil storage tank | power:1.5KW/ 380V/50Hz size:1400x1300x1850mm Function: Oil storage tank with heating function, with filter |

14. Oil filter | power:1.5kw size:450mm Function: The ultrafine particles in the oil are filtered out, and the oil flowing out of the oil outlet is the oil that meets the requirements. It is connected to the fryer through the pipeline to complete the dynamic filtering, thereby completing the entire filtering process. |

15. Fuel tank | Function: The fuel tank is equipped with a heating device, and the oil that needs to be added is heated to a certain temperature through the heating pipe, and then sent to the inside of the fryer through a circulating pump to achieve the purpose of adding oil. |

16. Vibration degreasing machine | power:0.25KW size:1800*1000*1300mm Function: Under the high-frequency vibration of the vibration motor, the oil on the surface of the potato strips is fully removed, and the material advances into the air mainline under the vibration state. |

17. Air-dry cooling line | power:0.75KW size:5000x1100x1600mm |

18.Hoist | power:0.75KW/380V/50Hz size:2000*800*1600mm |

19. Roller seasoning machine | power:1.5KW/380V/50Hz size:2400*1000*1600mm |

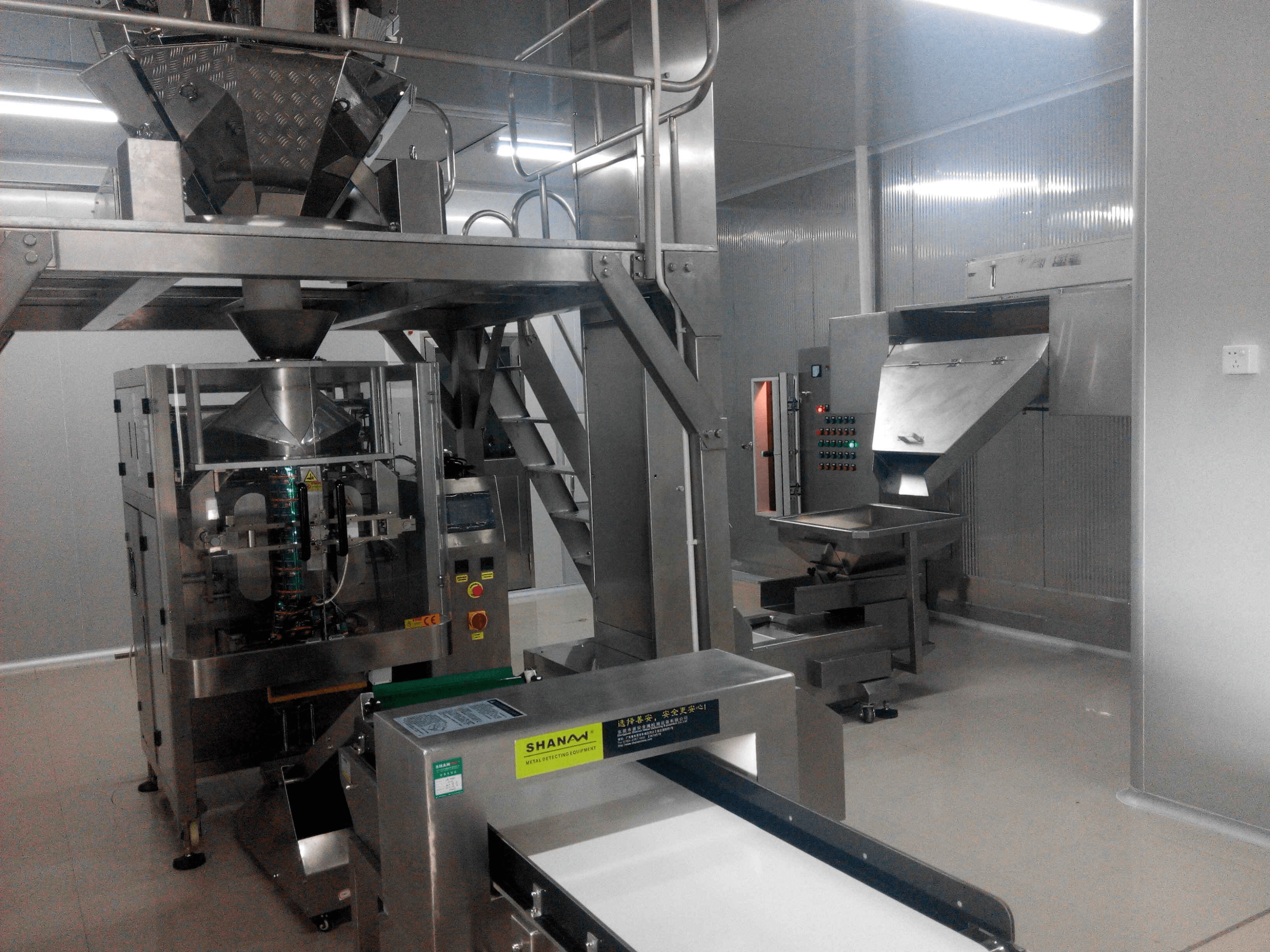

20Ten-head automatic packaging machine | Voltage:220v size:1.6m |