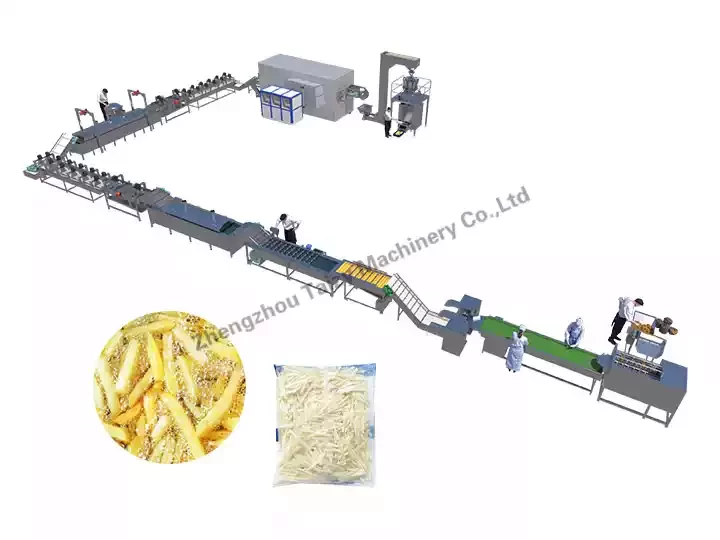

This fully-automatic frozen french Fries production line is designed and installed according to the customer’s needs. It mainly consists of washing machine, picking table, cutting machine, blanching machine, frying machine, and some other related auxiliary equipment.

Detailed parameters of the whole frozen French fries production line

| Item | parameters |

| capacity | 1000 kg/h |

| blanching temperature | 95 degree |

| blanching time | 30 s |

| de-water/de-oil time | 2 mins |

| frying temperature | 160-180 degree (the temperature can be adjusted) |

| frying time : 40-60s | 40-60s(for frozen french fries) |

| power consumption/day | about 483kw(When the machine runs smoothly, it only needs half the power.) |

| oil consumption/day | 5%(the first time fryer machine need to put 2T) |

| water consumption/day | 500–600kg |

| working area | about 1000 ㎡ |

| workers number | 6-10stuffs |

| machine material | 304 stainless steel |

| transportation | need 6 *40HQ Containers |

Equipment specifications of frozen french fries production line

| No | Item | specification |

| 1 |  sorting machine | Machine size : 5500*1800*1200mm Weight : 2200kg Capacity : 1000kg/h Voltage : 380v 50hz Power : 1.5kw Remarks : 304 stainless steel; 3-5levels according to customers’ demands; with hoist |

| 2 |  Silo | Size: 2000*1330*1200mm Power: 1.1Kw Capacity: 2t/h Remarks: 304 stainless steel. |

| 3 |  Hoist | Power: 0.55 kW Voltage: 380 v 50 Hz Size: 1800*800*1500 mm Functions: The raw potatoes are removed by this hoist into the pre-washing machine. Remarks: The electric appliance used is the Schneider brand, the inverter is Mitsubishi of Japan, and the motor speed is adjustable; PVC and 304 stainless steel. |

| 4 |  Pre-washing machine | Power: 4.37kw Voltage: 380 v/50 Hz Size: 3400*900*1400 mm After the potatoes are lifted, they enter the pre-washing machine, and the dirt on the surface of the potatoes is cleaned by rolling and spraying, and then the next step is performed. Remarks: 9pcs hair rollers; with a circulating filtering water tank at the bottom; automatically discharged by screw driving; the peeling time and speed can be adjusted; the inverter is the Japanese Mitsubishi inverter, and the electrical appliances are brand Schneider. |

| 5 |  Washing machine | Power: 4.37 kW Voltage: 380 v/50 Hz Size: 3400*900*1400 mm Function: The pre-washed potatoes enter the peeling machine through a hoist, and are thoroughly peeled through a soft roller and water spray. Remarks: 9pcs hair rollers; with a circulating filtering water tank at the bottom; automatically discharged by screw driving; the peeling time and speed can be adjusted; the inverter is the Japanese Mitsubishi inverter, the electrical appliances are brand Schneider. |

| 6 |  Picking table | Power: 0.75 kW Voltage 380 v/50 Hz Size: 4000*800*950mm Functions: After the potatoes are peeled, they enter this equipment, and then they are manually picked to see if there are any defective or unqualified potatoes, or if the skins have not been washed off, and do some processing. Remarks: PVC and 304 stainless steel; the conveyor belt speed can be adjustable. |

| 7 |  Waste conveyor | Functions: feed trucks are placed on each side of the picking line. Waste materials can be conveniently put into it, and then dumped after each shift. The material is 304 stainless steel. Size : 600*400*500mm |

| 8 |  Cutting machine | Power: 2.2 kW Voltage : 380 v/50 Hz Size : 1200*1000*1400 mm Remarks : 304 stainless steel; thickness:7,9,10mm or according to client needs; Price includes 1 set of blade; Extra I set of blade 60 USD, only cut attached picture shape.  |

| 9 |  Bucket elevator | Power : 0.75KW Voltage : 380V/50Hz Size : 1800*1000*1500mm The lifting mesh belt used is stainless steel 304 mesh belt, the mesh diameter is 3mm, the frame body used is 50502mm high quality 304 stainless steel square tube and 2mm stainless steel, the bearing is stainless steel 316 bearing, the motor used is high quality copper wire adjustable speed Motor; frequency converter is Japan Mitsubishi frequency converter; electric is brand Schneider. |

| 10 |  Dust cleaning machine | Size : 2600*1000*1400 mm Power : 1.5 kw Voltage : 380 v/50 hz Functions : After cutting the French fries, use a rinse machine to mention the top of the impurity removing machine. By setting the gap between the hair roller and the hair roller, generally 4mm soft hair roller, the fries go forward under the action of the hair roller, below The fries will leak out between the hair rollers, and there is a receiving box below to achieve the purpose of screening. Wool roller material is high-quality nylon wire and meets food requirements. |

| 11 |  Bubble washing machine | Power : 5.5kw Voltage : 380v/50Hz Size : 6000*1200*1400mm Belt width : 800mm; machine length: 6m Through the bubble wave cleaning, the potato strips are rolled, and the starch and the like on the surface of the potato strips are fully washed, and the secondary water spray cleaning function is provided. Remarks: 304stainless steel; with wheels |

| 12 |  Blanching machine | Heating Model : Electric heating Power : 120 kw Voltage : 380 v/50 Hz Weight : 1400 kg Size : 6000*1200*1400 mm Belt width : 800mm; machine length: 6m Functions : After then, the chips enter the blanching machine. The mechanism stops the enzyme activity in the potato strips, maintains the original vivid color of the potato strips, improves the softness of the cells, and facilitates the evaporation of moisture. Remarks: electric heating; the water temperature can be controlled; material 304 stainless steel; The mesh belt motor is a speed regulating motor and the thickness of the insulation layer is 70mm, which effectively prevents heat loss. |

| 13 |  De-water machine | Power : 0.55 kw Voltage : 380 v/50 Hz Size : 1800*1500*1300 mm Functions : Blanched potato chips are conveyed to the vibration de-waterer through mesh belt, and the surface moisture is removed by high frequency vibration. Remarks : The material used in this machine is 304 stainless steel, the thickness of plate is 3mm, the frame square tube is 100505mm high quality 304 stainless steel square tube |

| 14 |  Air cooler | Power : 13.6 kw Voltage : 380 v/50 Hz Weight:700 kg Size : 5000*1200*1600 mm Belt width : 800mm; machine length: 5m After the fries are vibrated, they pass through the air-drying line to effectively and completely remove moisture. The working principle is that the cut potato strips are transmitted through a mesh belt and turned over several times to achieve the multi-faceted and uniformity of the material by the wind. Cool and dry the moisture on the surface of the potato strips. The air nozzle is designed as a knife, which effectively increases the air pressure, so that the moisture on the surface of the material is blown away in a short time, which is convenient for subsequent processes. Remarks: This air trunk line is all made of high-quality 304 stainless steel, frequency conversion speed regulation, mesh belt form is 6 turns and one flat, mesh belt width is 1200mm, 16 fans, each 0.75KW, the fan inlet uses a dense hole filter system, and the fan height is adjustable The bearing is a high-quality stainless steel bearing. |

| 15 |  Hoist | Power : 0.75 kw voltage : 380 v/50 hz Size : 2000*1500*1350 mm Remarks : 304 stainless steel |

| 16 |  Frying machine | Power : 200 kw voltage : 380 v/50 Hz Weight : 1500 kg Size : 10000*1200*2400 mm Belt width : 800mm; machine length: 10m Functions : The working principle is as follows: after blanching and air-drying, the potato chips are raised from the hoist to the entrance of the fryer, the oil temperature is set to 185 degrees, the second oil temperature is set to 160 degrees, the third oil temperature is set to 120 degrees, and the potato chips are fried in the oil for about 1-2 minutes, then exported by the conveyor belt and enter the next deoiling process. This fryer is heated by electricity. Remarks : The equipment adopts pure frying technology and is equipped with dynamic filtering system. It realizes automatic filtering and slag discharging in the working process, guarantees the quality of frying oil. 304 stainless steel; variable frequency speed regulating motor, three-stage temperature control; equipped with automatic lifting function, which is conducive to cleaning and sanitation; equipped with electrical components are brand Omron or Schneider brand. |

| 17 |  Oil filter | Coarse filter tank diameter : 300mm Circulating pump : 1.5kw Material : 304 stainless steel |

| 18 |  Oil storage tank | Power : 1.5Kw/set Stainless steel Thickness : 3mm |

| 19 |  De-oil machine | Power : 0.55 kw Voltage : 380 v/50 Hz Size : 1800*1500*1300 mm Functions : Blanched potato chips are conveyed to the vibration de-waterer through mesh belt, and the surface moisture is removed by high frequency vibration. Remarks : The material used in this machine is 304 stainless steel, the thickness of plate is 3mm, the frame square tube is 100*50*5mm high quality 304 stainless steel square tube |

| 20 |  Air cooler | Power : 13.6kw Voltage : 380 v/50 Hz Size : 5000*1200*1600 mm Belt width : 800mm; machine length: 5m After the fries are vibrated, they pass through the air-drying line to effectively and completely remove moisture. The working principle is that the cut potato strips are transmitted through a mesh belt and turned over several times to achieve the multi-faceted and uniformity of the material by the wind. Cool and dry the moisture on the surface of the potato strips. The air nozzle is designed as a knife, which effectively increases the air pressure so that the moisture on the surface of the material is blown away in a short time, which is convenient for subsequent processes. Remarks : This air trunk line is all made of high-quality 304 stainless steel, frequency conversion speed regulation, mesh belt form is 6 turns and one flat, mesh belt width is 1200mm, 16 fans, each 0.75KW, the fan inlet uses a dense hole filter system, and the fan height is adjustable The bearing is a high-quality stainless steel bearing. |

| 21 |  Hoist | Power : 0.75 kw voltage : 380 v/50 hz Size : 2000*1500*1350 mm Remarks : 304 stainless steel |

| 22 |  Distributing machine | Size : 6000*1200*1300mm Power : 0.5kw Working principle : under the high frequency vibration of the vibrating motor, evenly distribute the potato chips on the quick-frozen net belt to prevent the chips from sticking together. The material used is 304 stainless steel, the thickness of the plate is 3mm, the square tubes of the frame are 100 * 50 * 5mm high-quality 304 stainless steel square tubes, the vibration motor is 0.25kw, and the vibration amplitude is adjustable. |

| 23 |  Freezer | Mesh belt width : 1000mm Machine length: 11m Size : 11000*2200*2400mm Quick freezing time : 7-35mim (adjustable) Feeding temperature : <15℃; Discharging temperature: -18℃ Temperature : -33~-35℃ Stainless steel thickness : outer thickness of the library plate 0.8mm, inner thickness 0.6mm, mesh belt bracket 50*50/3mm, guard plate 2mm |

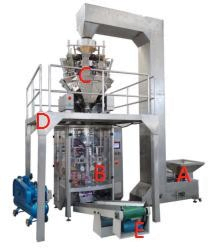

| 24 |  Packing machine | A.Feed conveyor Delivery value:3-6m³/h Voltage : 380v Weight:500kg B.TZ-720 Vertical Automatic Packaging Machine Bag length : 100-400mm(L) Bag width : 180-350mm(W) Max width of roll film : 720mm Packing speed : 5-50bags/min Measuring range : 6000ml(Max) Air consumption : 0.65Mpa Gas consumption : 0.4m³/min Voltage : 220VAC/50HZ Power : 5kw Dimension : 1780*1350*1950mm C.10 Buckets Multi Head Weigher Machine Maximum weighing : 1000g Single weighing range : 10-1000 g Weighing accuracy : ±0.3~1.5 g Weighing speed : Max 3000cc Control unit : 8.4 inch key screen D.Platform Non-slip countertop, guardrail around, practical and safe. E.Finished product conveyor |

Spare parts of 1000kg/h french fries production line

| No | Name | Spare parts for free | Spare parts for charging free |

| 1 | Water bucket conveyor | Button Switch 1 pcs Relay 2 pcs  | P206 bearing Block 2 Pcs 6905 bearing 2 Pcs  |

| 2 | Pre-wash machine | Button Switch 1 pcs Triangle belt 2 pcs  Chain 1 Set  Sprayer 20pcs  | Brush Roller 9 pcs P206 bearing block 18 pcs Chain Wheel 10 pcs  |

| 3 | Water conveyor | Button Switch 1 pcs Relay 2 pcs | P206 bearing Block 2 Pcs 6905 bearing 2 Pcs |

| 4 | Emery peeling machine | Button Switch 1 pcs Triangle belt 2 pcs Chain 1 Set Sprayer 20pcs | Emery rollers 4 pcs |

| 5 | Picking table | Button Switch : 1 pcs Relay 2 pcs | P206 Bearing Block 2 Pcs 6905 bearing 2 Pcs Conveyor belt1 pcs  |

| 6 | Cutter machine | Triangle belt 2 pcs | 3 different size blades ( 7,9, 12mm) |

| 7 | Bucket elevator | Button Switch : 1 pcs Relay 2 pcs | P206 bearing Block 2 Pcs 6905 bearing 2 Pcs |

| 8 | Dust cleaning machine | Button Switch 1 pcs Relay 2 pcs Sprays 10pcs  | L206 Bearing Block 20 pcs Chain 5 pcs  |

| 9 | Bubble washing machine | Button Switch 1 pcs Relay 2 pcs Sprayer 10pcs | P206 bearing Block 2 Pcs 6905 bearing 2 Pcs |

| 10 | Blanching machine | Button Switch 1 pcs Relay 2 pcs Thermocouple 1 pcs  | P206 Bearing Block 2 pcs 6905 Bearing 2pcs Temperature Controller 1pcs  |

| 11 | De-water machine | Button Switch 1 pcs Relay 2 pcs | Vibration Motor 2 Set |

| 12 | Mesh belt dryer | Button Switch 2 pcs | Electric heating tube 3pcs Fan motors 2pcs P206 Bearing Block 2 Pcs 6905 Bearing 2 Pcs |

| 13 | Hoist | Button Switch 1 pcs Relay 2 pcs | P206 Bearing Block 2 Pcs 6905 Bearing 2 Pcs |

| 14 | Fryer | Button Switch 1 pcs Relay 2 pcs | P206 Bearing Block 2 pcs P207 Bearing Block 2 pcs PL206 Bearing Block 2 pcs |

| 15 | Oil filter | Button Switch 1 pcs Electrical Components 2 pcs Thermocouple 1 pcs | Electric Heat Pipe 3 pcs Temperature Controller 1 pcs  |

| 16 | Deoil machine | Button Switch 1 pcs Relay 2 pcs | Vibration Motor 2 Set Spring 4 Pcs |

| 17 | Air cooling machine | Button Switch 1 pcs Relay 2 pcs | P206 Bearing Block 6 pcs P207 Bearing Block 2 pcs Draught Fan 2 pcs  |

| 18 | Hoist | Button Switch 1 pcs Relay 2 pcs | P206 Bearing Block 2 Pcs 6905 Bearing 2 Pcs |

| 19 | Distributing machine | Button Switch 1 pcs Relay 2 pcs | Vibration Motor 2 Set Spring 4 Pcs |

| 20 | Continuous freezer | Suction filter core 2pcs Liquid supply filter element 2pcs Oil filter element 2pcs Solenoid valve coil 2pcs Mesh belt 1m Rapping block 2pcs Electrical insurance 2pcs | Evaporative cold water pump 1 set Evaporative air cooler 1 set Quick-freezing tunnel air cooler (low temperature) 2 sets Danfoss expansion valve 2 pcs The electromagnetic valve 2 sets Frozen oil 1 pcs barrel Compressor AC contactor 2 pcs Other AC contactors 3pcs |

Some details about French fries production equipment

Washing and peeling machine

- Hair rollers 9pcs.

- A circulating filter water tank at the bottom can effectively save water resources.

- The potatoes are automatically discharged through the screw drive.

- The equipment is made of 304 stainless steel with a thickness of 3mm. The frame is made of 304 stainless steel of 50*50*4mm. Bearings are 316 stainless steel.

- The washing and peeling machine has adjustable feet and a removable universal wheel for easy transportation.

Rinsing machine

- Universal wheels move and fix the feet.

- A surfing function can be added, Push materials forward, and water valve control speed.

- High-pressure spray, and Secondary spray, washing more cleaner.

- Frequency converter and electric control cabinet: can set washing speed.

The rinsing machine has no damage to vegetables and fruits. It can be used to clean vegetables and fruits such as mango, lemon, orange, jujube, tomato, pepper, etc.

The equipment is made of 304 stainless steel with a thickness of 2MM. The frame is made of 304 stainless steel of 60 * 40 * 2mm. The equipment has adjustable feet and a removable universal wheel for easy transportation, Equipped with a filter circulating pool, and high-pressure water spray.

Air dryer

- The air inlet of the fan adopts a dense hole filter system, the height of the fan is adjustable, and the high-quality stainless steel bearing.

- The working principle is to transfer the blanched potato strips through the mesh belt and turn it over many times to realize the multi-faceted wind and uniformity of the material.

- The high-pressure wind of the blower cools the food and removes the moisture on the surface of the potato strips.

- The height of the fan can be adjusted by adjusting the screw.

- Multi-key start, segmented control of the number of fans, if one group is damaged, the others will not be affected, and production can be reduced without stopping production.

What value-added services can we provide?

QC system

We have a strict quality control system; from raw material, production, test, delivery to after-sales services.

Raw material procurement control

Our factory has a special purchasing department, which strictly controls the purchase of raw materials. Every accessory such as screws, gears, steel plates, locks, etc. is very important; especially for machinery, the most important part is the electrical part. If the electrical appliance breaks down, the entire machine will have to stop working, so it is very important to choose a good electrical appliance.

We have a 1-year warranty and exported many machines to different countries. No customer response problems until now.

Production control

The workers in our factory are all experienced masters, and they have a better understanding of the structure of every part of the machine; Professional welding technology.

A professional product quality inspector will visit the worker’s machine from time to time to check the work progress and work results; in addition, they will check the product, record the inspection results of the machining, welding, and coating procedures to determine what the worker controls independently Whether the result meets the requirements will not be put into storage until it is judged as qualified.

Pre-shipment inspection

Before shipment, we will debug the machines and test them and make a video for you. If there is a problem of unqualified, we will make a new machine for you, and give you a 5% discount on the next purchase of the machine as a sincere apology.

Package system

- Machines are wrapped in plastic film first before packing, which is to avoid moisture on the sea.

- The machines are putted in a wooden case which is free of fumigation, lined with metal wire if necessary.

Storage system

We have a dedicated warehouse to store the stock, which is convenient for customers to ship the goods in the shortest time after placing the order.

After-sales service system

- All products purchased in our company are guaranteed to keep in good repair for one year. Malfunctions which are caused by machine-self and quality will be responsible for our manufacturer. Other malfunctions which are caused by operation mistakes, man-made problems, etc will be responsible for clients-self.

- Operation video & instruction will be sent to clients, to help them use the machines better.

- Any problems occur while using, professional advice will be offered. Additionally, our company provides technical support and fittings for life. After-sales service isn’t restricted by time and we will solve your problems in time. If you are caught in some problems when using our products, welcome to contact us at any time.

- 24 hours hot line.

If we cooperate, we can also provide the following services for free

- Our factory will have a promotional event every quarter, and every event in the future can reserve a place for you.

- If you want to be an agent, we can promote products for you and also recommend local customers.

- Evaluation feedback: Once a month, make a video call with the person in charge of the factory to check the operation of the machine. Collect the problems so that the next cooperation can be carried out more smoothly.

- If possible, our manager will visit our cooperate client every year, do the further feedback and know client local market, hope can build long, stable, influence business relations.