The client, located in northern Spain, is a medium-sized food enterprise specializing in frozen food processing and export. It has long supplied frozen French fries to local restaurant chains, supermarkets, and wholesalers. With order volumes steadily increasing, the client decided to introduce a complete frozen French fries processing line to enhance overall production capacity and ensure product consistency.

Frozen French fries processing line configuration

Based on the client’s existing facility conditions and target production capacity, both parties confirmed the frozen French fry processing line solution for this shipment.

The complete line includes a potato brush washer and peeler, potato cutter, blanching and frying unit, dehydrator and oil separator, and vacuum packaging machine. This enables continuous operation from raw material processing to finished product packaging.

During the solution confirmation process, the client prioritized seamless equipment integration and compatibility with existing freezing equipment.

Equipment production and shipping arrangements

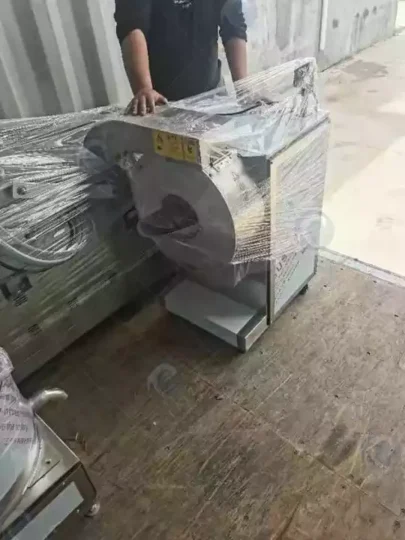

Following confirmation of technical details and delivery schedules, the factory expedited equipment manufacturing, commissioning, and full-line integration testing. The production line was packaged in modular sections to ensure safety and integrity during long-distance ocean transport.

The complete frozen French fry processing line has now been successfully containerized and shipped to Spain, accompanied by relevant technical documentation and operating manuals.

Cooperation progress and plans

The client stated that introducing this frozen French fry processing line represents a crucial step in upgrading their production capabilities. Once the equipment is installed and operational, it will significantly expand the supply of frozen French fries to local and surrounding European markets. We remain in ongoing communication regarding subsequent technical support and potential Phase II expansion plans.