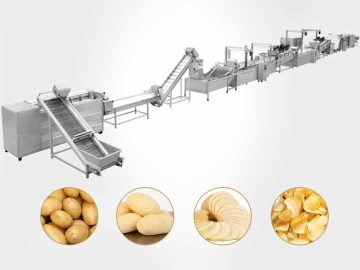

At the end of last month, we completed the manufacturing of a semi-automatic frozen French fries production line and successfully shipped it to Uganda. The customer is a company specializing in food processing, primarily engaged in frozen French fries and other snack foods.

Purchase reasons and procurement requirements

Through market research and technical evaluations, the client identified our semi-automatic frozen French fries production line for its high efficiency, user-friendly operation, and robust stability.

Compared to traditional manual processing, this integrated system automates multiple stages—potato washing, slicing, blanching, dehydration, pre-frying, and freezing—significantly reducing labor requirements while enhancing production efficiency and product consistency.

Frozen French fries production line features

- Integrated processing: combines washing, slicing, blanching, dehydration, pre-frying, and freezing into one system, boosting production efficiency.

- User-friendly operation: semi-automated design with an intuitive interface allows for quick operator training and reduced labor costs.

- High-capacity efficiency: continuous operation ensures large-scale french fry production while maintaining consistent texture and quality.

- Energy-efficient durability: constructed with premium materials for stable performance and low energy consumption, minimizing long-term operational costs.

- Flexible adaptability: production speed and processing flow can be adjusted to accommodate varying output requirements, suitable for diverse production scales.

For more information on our semi-automatic frozen French fries production line, please click the link below: https://potatochipsprocessing.com/french-fries/semi-automatic/.

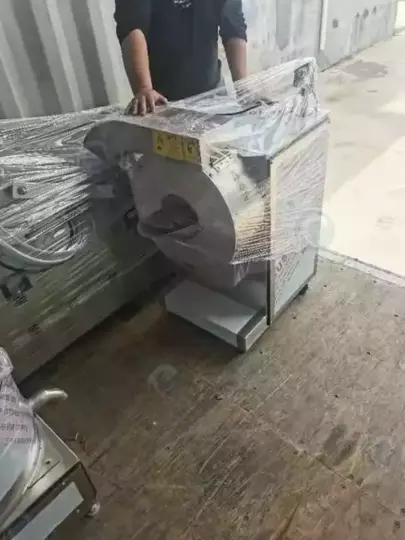

Shipping site showcase

On the shipping day, our staff rigorously inspected, secured, and loaded the complete equipment set according to export standards, ensuring safe and undamaged transportation.

The loading process proceeded efficiently and orderly, with the equipment successfully loaded into containers ready for shipment to Uganda. The client monitored the loading and shipping site via real-time video, expressing high recognition for our professional service and logistics arrangements.