In Iraq, the French fries processing business is now a very popular investment project. Taizy’s French fries production line and different deep-fried French fries processing schemes have been favored by many Iraqi customers. In order to meet the needs of different customers, we have configured various specifications of French fries processing lines for customers in Iraq and other countries to choose from, such as small-scale French fries processing line, semi-automatic French fries plant, large-scale French fries production line, etc., with the output between 100kg/h and 500kg/h. Recently, another Iraqi customer ordered a deep-fried french fries production line with a capacity of 200kg/h from our factory.

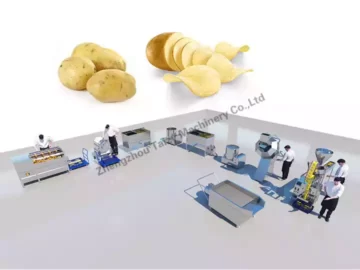

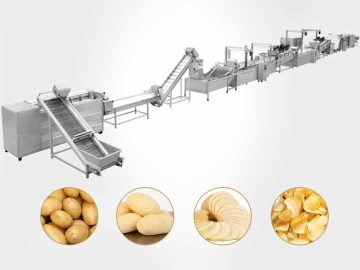

200kg/h French fries production line configuration

In fact, the output of the French fries production line can be customized according to customer needs, so no matter how large the fries processing plant is required by the fries processor, our factory can provide a processing plan at a favorable price.

The 200kg/h French fries production line usually includes brush type potato washing and peeling machine, potato cutting machine, blanching machine, automatic dehydrator, deep fryer machine, degreasing machine, seasoning machine, and French fries packaging machine.

However, the Iraqi customer’s factory has already purchased a fryer with an output of 300 kg/h, so this time only other equipment for the French fries line was purchased.

Why doesn the Iraqi customer produce frozen French fries?

Usually, 80% of our customers will choose to purchase frozen French fries processing line to produce frozen fries, because the production cost of frozen fries is lower and the output is larger. However, the Iraqi customer chose to produce fresh French fries. Why is this?

The main reason the Iraqi customer chose to process fresh French fries was that the customer’s local demand for fresh French fries was very large. The customer stated that although there are many fast-food restaurants in the city where they sell fresh fries, their output is very small and daily sales are also very small.

This leads to a situation where there are always many consumers who buy fries queuing to buy fries. The customer analyzed that the output of French fries in fast food restaurants was low because they chose to make French fries by hand or buy frozen fries for reprocessing in order to save costs.

The customer believed that he can invest in a deep-fried French fries processing plant to produce crisp fries in large quantities and distribute the prepared fries to various restaurants, fast food restaurants, snack shops, etc.