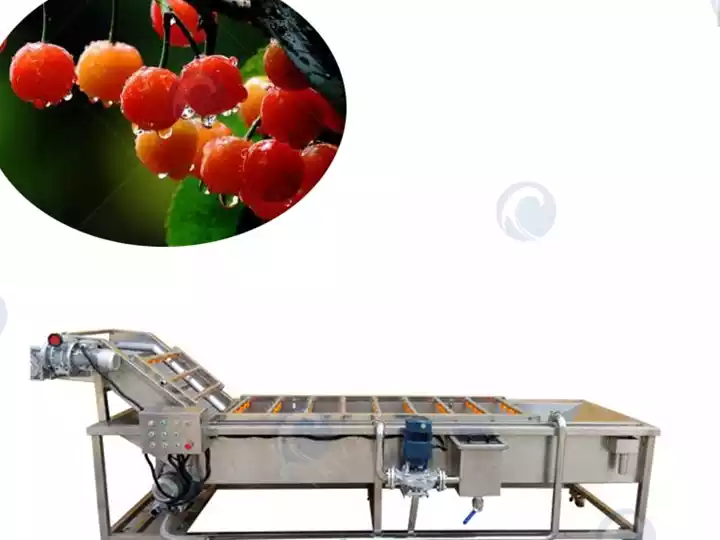

In the fresh-cut vegetable processing, central kitchen, and primary agricultural product processing industries, air bubble washer machines are increasingly becoming the mainstream equipment for vegetable cleaning due to their superior cleaning performance, high efficiency, and low operating costs.

High-efficiency gentle cleaning method

Bubble washers generate dense clusters of bubbles in water through a blower system. The turbulent water flow created as bubbles rise and burst effectively strips away surface dirt, debris, and some pesticide residues from vegetables.

The entire cleaning process relies primarily on water flow and bubble impact, eliminating the need for vigorous friction. This ensures thorough cleaning while preventing damage to leafy vegetables.

Practical testing shows bubble washing achieves over 90% removal of surface dirt, making it particularly suitable for delicate vegetables like lettuce, spinach, broccoli, and cilantro.

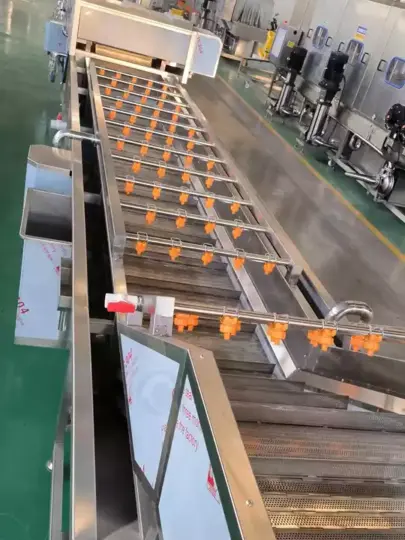

Reduced labor and operational costs

Bubble washers support continuous operation with typical processing capacities ranging from 300–2000 kg/h, allowing flexible selection based on output requirements. A single medium-sized bubble washer can replace 5–8 workers, boosting overall cleaning efficiency by 3–5 times and effectively alleviating labor shortages.

Additionally, the equipment operates stably with simple controls, allowing one operator to manage loading, washing, and unloading. This makes it particularly suitable for large-scale vegetable processing plants, pre-washed vegetable distribution centers, and primary agricultural processing facilities.

Energy and water-saving air bubble washer machine

Typically equipped with a water recirculation filtration system, bubble washers collect and filter sediment and impurities, enabling reuse of cleaning water. Compared to traditional water-rinsing methods, this achieves overall water savings of 30%–50%.

With power ratings typically ranging from 3–7.5 kW, the equipment features low energy consumption and controllable operating costs, offering long-term economic advantages. Additionally, select models can be equipped with optional ozone or disinfection modules to perform sterilization during the washing process, further enhancing food safety standards.

Conclusion

Air bubble washer machines are suitable not only for leafy greens and root vegetables but also for preliminary cleaning of fruits and aquatic products.

Overall, bubble washers offer distinct advantages in cleaning effectiveness, production efficiency, and operational costs, making them a crucial equipment choice for modern vegetable processing enterprises aiming to achieve standardized and large-scale production.