As a ready-to-eat nutritious snack, fried banana chips have become increasingly popular in the market. Recently, customers from many African countries have ordered our small banana chips production line to produce fried plantain chips and banana chips, such as Nigeria, South Africa, Kenya, and Ghana.

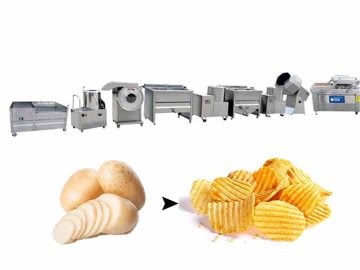

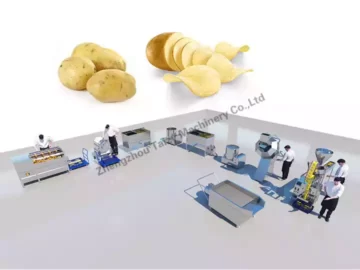

What equipment does the small banana chips production line mainly include?

- Green banana peeling machine. Mainly peel the unripe banana from the banana.

- Banana slicer. Quickly cut peeled bananas into slices of uniform thickness.

- Banana slice blanching machine. The main purpose of the blanching of banana slices is to remove the starch on the surface to ensure its bright color.

- Banana slice dryer. The machine uses multiple sets of high-speed fans to quickly remove water droplets on the surface of banana slices.

- Banana chips fryer. It is best to select a continuous fryer for the frying process, which has a higher frying efficiency.

- Deep-fried banana chips degreaser. It can quickly remove excess oil droplets on the surface of fried banana chips.

- Banana chips seasoning machine. The machine can be used to prepare fried banana chips into various flavors.

- Banana chips packaging machine. The machine can be used to quickly pack banana chips into packages of uniform weight.

Details about the Ghana order for 100kg/h banana chips line

The Ghanaian customer is the first to invest in a banana chip production project. He originally planned to purchase a 50kg/h small banana chip production line.

His factory has 10 workers, and the employment price of the workers is not high, so we recommended him a 100kg/h banana chip processing line with more investment advantages. After considering all factors, the client agreed with our proposal.

Because the local electricity price of the customer is very expensive, the customer chose a gas-heated fryer with an output of about 100 kg/h. After further confirming the details, the customer finally placed an order.