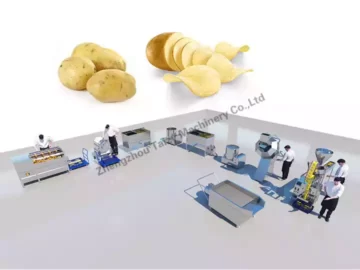

Recently, the customized potato chips production line solution we provided for a client in the Faroe Islands has led to tremendous success in their fiercely competitive food market. Let’s delve into the details of this successful collaboration.

Improve productivity and efficiency

Our client, a food production company based in the Faroe Islands, specializes in producing various types of potato chips and other snack foods. One of the main challenges facing the client is the need to update their existing potato chips production line. Their previous production line had some aging equipment and efficiency issues, leading to low production efficiency and inconsistent product quality.

Satisfy customer’s request

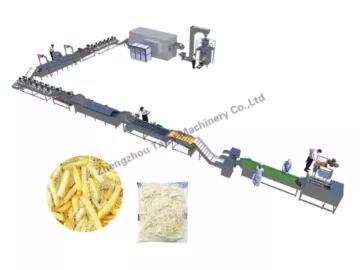

After communication, our manager gave a rough estimate of the capacity required for their french fries production line and recommended a 500kg/hour production line. We provide advanced washing and cutting equipment, frying equipment, seasoning and packaging equipment, and ensure that the shape, thickness, color appearance, and taste of potato chips meet customer requirements.

Positive feedback from Faroe Islands customer

The new potato chips production line has significantly boosted the client’s capacity and production efficiency, enabling them to expand their market share and further solidify their leading position in the snack market of the Faroe Islands.