One of the key steps in making delicious French fries is washing and peeling the potatoes. Effectively washing and peeling potatoes not only makes food healthier and safer but also ensures the quality and taste of your fries.

Why give up washing and peeling potatoes by hand?

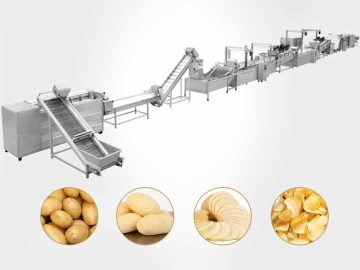

Traditional manual cleaning and peeling is not only time-consuming, labor-intensive, and inefficient, but can also easily lead to food waste due to uneven peeling. For this reason, the high-efficiency potato washing and peeling machine we launched came into being to solve this problem and make French fries easier, faster, and more efficient.

Advantages of washing and peeling machine

Excellent cleaning effect: rows and rows of hair rollers can effectively remove the dirt on the surface of vegetables, including soil, sand, pesticide residues, and so on.

Efficient performance: The washing and peeling machine has large-capacity continuous processing capabilities. TZ-2600 potato washing and peeling machine can process 2400kg of potatoes per hour. It can easily wash away impurities and dust from potatoes.

User-friendliness: its operation is also very simple, just put the vegetables into the machine and tap the switch.

Focus on food safety: the parts in contact with the ingredients are made of 304 stainless steel, which better ensures food safety during the production of French fries.

Working Principle of washing and peeling Machine

The washing and peeling machine mainly consists of a wool roller, a rotating device, a water pump, and a drainage device.

When using it, we put the potatoes into the wool roller vegetable washing machine, press the switch, and the rotating device starts to drive the wool roller to rotate. A small water pump will supply water to the machine.

Rows of wool rollers rotate rapidly and sweep over the surface of potatoes in turn. The clean water and dirt on the potato surface are mixed and fall into the drainage device. The sewage is discharged, and the potatoes continue to be cleaned, and finally reach the discharge port.