Great news! We have shipped a brush type washing machine to a South African client engaged in seafood processing and export trade. This client specializes in cleaning, sorting, freezing, and packaging aquatic products such as fish, shrimp, and shellfish, exporting goods to multiple African countries and select Middle Eastern markets.

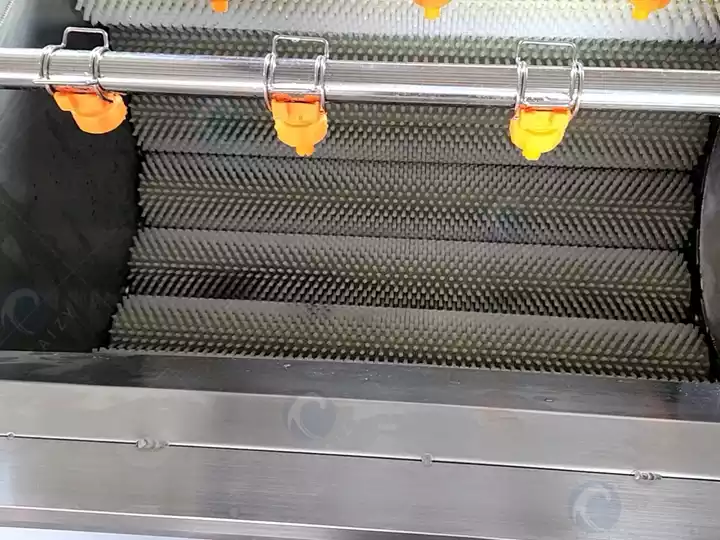

Features of brush type washing machine

- This brush type washing machine has a capacity of 500kg/h. Constructed entirely from food-grade stainless steel, it features a compact design that is corrosion-resistant and easy to clean, meeting international food hygiene standards.

- Equipped with multiple sets of flexible nylon brushes and a high-pressure spray system, it delivers multi-directional, high-efficiency cleaning for seafood like fish, shrimp, and shellfish, thoroughly removing sand, impurities, and surface adhesions.

- Its adjustable speed design adapts to various seafood types and sizes, ensuring thorough cleaning while preventing damage to raw materials.

- Additionally, the equipment supports continuous operation, reducing labor costs and energy consumption, making it suitable for assembly lines in medium to large-scale seafood processing plants.

Shipping preparation and quality inspection

Prior to shipment, our production and quality control teams conduct comprehensive performance testing and trial runs on the brush cleaner, including water pressure, brush rotation speed, noise control, and corrosion resistance testing. This ensures stable operation under high-load conditions.

Packaging employs reinforced wooden crates with moisture-proof treatment and shock-absorbing securing methods to guarantee safe delivery to South African ports during long-distance sea transport.

Technical services and collaboration process

During the initial communication phase, the client provided our technical team with detailed information regarding their seafood product types, production line layout, and cleaning requirements. Tailored to the client’s specific needs, we delivered a customized solution encompassing brush material selection, water spray angle design, and energy efficiency optimization recommendations.

Additionally, we equipped the client with comprehensive English-language operating manuals and remote technical guidance services. This ensures smooth installation, commissioning, and operation, enabling rapid production start-up.

Equipment application advantages

The introduction of the automatic brush type washing machine not only significantly enhanced the client’s seafood cleaning efficiency but also improved the production environment and hygiene. It reduced manual handling steps, further elevating food safety standards.

In practical operation, this equipment can be integrated with sorting, air-drying, and packaging machinery to form an automated assembly line workflow, achieving full automation across the entire seafood processing chain.

In the future, the customer plans to continue expanding their production line and is considering purchasing more of our company’s supporting equipment, such as spiral washers, dehydrators, and graders, to build a more complete seafood processing system.