Client Profile & Project Objectives

The Canadian client is a company specializing in frozen food and potato product processing, primarily supplying semi-finished French fry and potato chip ingredients to local supermarkets and restaurant chains.

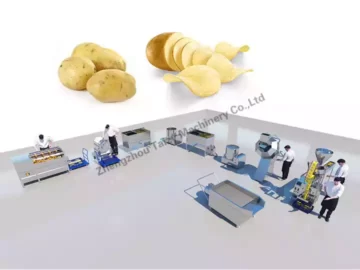

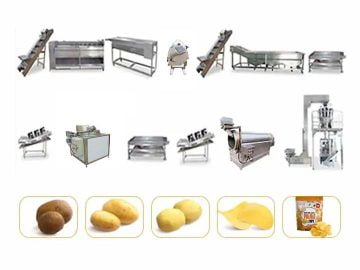

The client sought to establish a fully automated French fry production line encompassing washing, peeling, cutting, blanching, dehydration, frying, cooling, and quick-freezing packaging.

This integrated system aims to achieve standardized, continuous production while reducing labor costs and ensuring consistently golden-brown color and crisp texture in the final product.

Solution of French fry production line

Based on the client’s production capacity requirements and workshop layout, our company has tailored a fully automated French fry production line solution. Key equipment includes:

- Automatic Washing and Peeling Machine

- French Fry Cutter

- Blanching and Dehydration System

- Continuous Fryer

- Oil-Water Separation System

- Vibrating Oil Drainage Machine

- Quick Freezer and Automatic Packaging Machine

The entire line features stainless steel construction with automatic temperature control, energy-efficient heating, and easy cleaning/maintenance for efficient, hygienic production.

Shipping & Installation

This fully automated French fry production line has completed manufacturing and rigorous quality inspection at our factory. It has been successfully loaded into containers for shipment to Canada.

Prior to dispatch, our engineering team conducted comprehensive trial runs and factory commissioning to ensure rapid installation and operational readiness upon customer receipt.

Feel free to contact us anytime! Shuliy Group provides efficient, intelligent, one-stop production line solutions for food processing enterprises.