Banana chips or plantain chips are crispy snacks made of bananas that are sliced, baked, or fried. We can usually buy beautifully packaged banana chip snacks in supermarkets or snack shops. If we want to invest in banana chip production projects, how do we make commercial banana chips? The answer is to consider the industrial banana plantain chips production line.

Banana plantain chips production line for sale

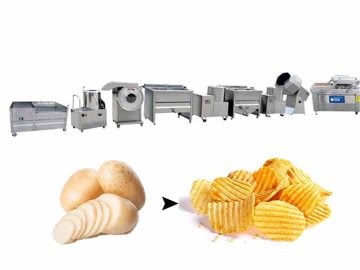

The large-scale processing of crisp banana chips and plantain chips in the industry requires the help of banana processing equipment. Because traditional hand-made banana chips are usually not very hygienic, and the yield is low, the processing cost is high.

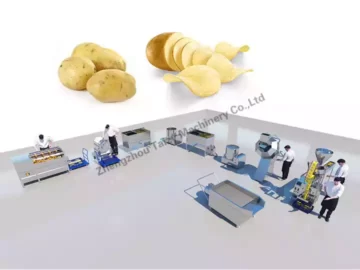

Using banana plantain chips production line to produce fried banana chips can double the output of banana chips and increase profits. Taizy machine is a food machinery manufacturer and supplier in China.

At present, it has provided customers in more than 40 countries and regions with a full set of banana chip production solutions, including the semi-automatic banana chip processing plant and the fully automatic banana chip processing plant. Therefore, no matter you have any questions about banana chip processing, our factory will provide you with a suitable solution.

Steps for making commercial banana chips

- Pick green bananas that are not fully ripe. The reason why we choose green bananas to make banana chips is that green bananas are not easy to break and can be peeled and sliced.

- Peel and slice. Use a commercial banana peeler to quickly peel the green bananas, and then use a slicer to cut the peeled bananas into slices with a thickness of 2mm.

- Fry the banana chips. Fry the banana slices using a continuous fryer. The frying temperature is usually around 180°C, and users can also adjust the temperature as needed.

- Cooling, seasoning, and packaging. The fried banana slices are usually very hot and need to be cooled to room temperature. Then, users can season and pack the banana slices as needed.