The Botswana-based client purchasing this potato chips manufacturing line has long been engaged in agricultural processing and snack distribution. Recognizing the rapid growth of the local snack market in recent years, they plan to launch their own brand of high-quality potato chips.

To ensure consistent product texture and controllable output, the client opted to introduce a complete set of automated potato chip processing equipment for large-scale production.

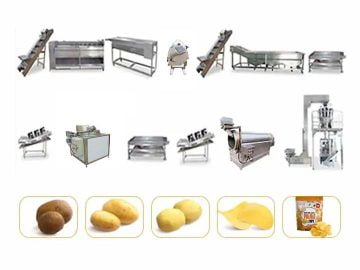

Potato chips manufacturing line features

This production line encompasses multiple stages including washing, peeling, slicing, blanching, dehydration, frying, seasoning, and packaging. With high automation throughout the entire process, it offers the following advantages:

- Consistent product texture: uniform slice thickness and precise frying temperature control.

- High efficiency & stable output: Ideal for continuous production in small-to-medium-sized food factories.

- Versatile application: processes various tuber ingredients including potatoes and sweet potatoes.

- Stainless steel construction: food-grade design ensures hygiene and easy cleaning.

This potato chip processing line equipment enables clients to rapidly enter the market, consistently supply premium potato chips, and enhance brand competitiveness.

Smooth collaboration with multiple solution refinements

During client consultations, we repeatedly adjusted equipment configurations based on local raw material specifications, desired texture profiles, and anticipated production capacity. We provided comprehensive production process plans, equipment layout diagrams, and operational recommendations.

The client expressed trust in our expertise, ultimately confirming the order and initiating production.

All equipment underwent pre-shipment debugging and quality inspection before being reinforced with impact-resistant, moisture-proof, and scratch-resistant packaging materials. The transportation plan was meticulously designed to ensure safe delivery to the client’s factory.