Fryers are usually divided into continuous fryers, square fryers, and vacuum fryers. I believe everyone is familiar with frying machines, but vacuum frying machines are a little unfamiliar. What is a vacuum fryer machine? What is the difference between a vacuum fryer and an ordinary fryer?

Introduction of vacuum fryer

The use of vacuum frying is very extensive. The principle of low-temperature dehydration frying is adopted, which reduces the temperature of frying without changing the taste of frying, and the vacuum fryer enhances the security of frying based on the principle of design. The small fryer we can see above produces greasy and unhealthy food. If you use a vacuum frying machine, you can solve these problems.

The difference between a vacuum fryer and an ordinary fryer

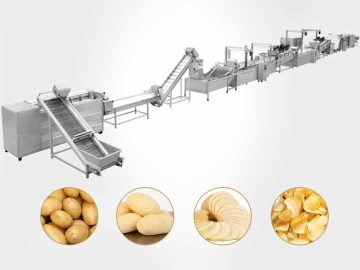

The vacuum fryer dehydrates and fries food in a vacuum state, and the required temperature is very low. The food produced is green and healthy, can maintain the original color and aroma, and also greatly reduces oil consumption and saves costs. The fryer is general high-temperature frying. The advantage of using a vacuum fryer is that it can alleviate the problem of food burning in the market, and can also solve the problem of mass production.

Advantages of vacuum fryer

- Color retention effect: In vacuum frying, the frying temperature is greatly reduced, and the oxygen concentration in the fryer is also greatly reduced. Fried food is not easy to fade, discolor, ed and brown, and can maintain the color of the raw material itself. For example, kiwi fruit is very susceptible to browning by heat, and it can keep its green color if it is vacuum-fried.

- Fragrance preservation: vacuum frying is adopted, and the raw materials are heated in a sealed vacuum state. Most of the flavor components in the raw materials are water-soluble and do not dissolve in oils and fats, and with the dehydration of the raw materials, these flavor components are further concentrated. Therefore, the use of vacuum frying technology can well preserve the aroma of the raw material itself.

- Reduce the degree of oil deterioration: The deterioration of frying oil includes oxidation, polymerization, thermal decomposition, and hydrolysis is mainly caused by water or water vapor in contact with oil. In the process of vacuum frying, the oil is in a negative pressure state, and the gas dissolved in the oil quickly escapes in large quantities, the generated water vapor pressure is small, and the frying temperature is low, thus greatly reducing the deterioration of the oil.

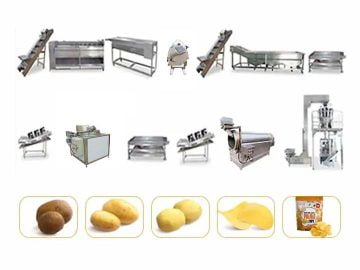

What is the composition of the vacuum frying machine?

1. Basic structure: automatic oil temperature control system, automatic lifting system.

2. Heating system: electric heating tube, heat transfer oil, coal, natural gas, liquefied gas, electromagnetic induction heating, infrared heating.

3. Mesh belt conveying system: frequency conversion speed regulation, quantitative conveying, and timing conveying.

4. Automatic filtration system: the dynamic circulation system of the vacuum fryer.