The UK client who purchased this frying machine is a processing company specializing in high-end snack foods. Their main products include Scotch eggs, French fries, and various fried snacks. The client has strict requirements for the taste, color, and evenness of frying of their products and hopes to improve production efficiency and ensure product quality by introducing high-performance frying equipment, while also meeting the frying needs of different food sizes.

Main features of frying machine

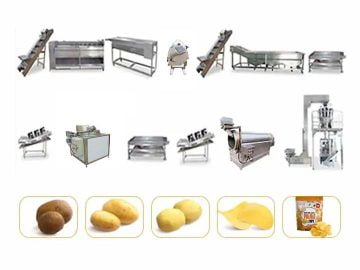

The 2.5-meter mesh belt electric heating fryer shipped in this case has the following core advantages:

- Moderate mesh belt width and length: 400mm mesh belt, 2.5 meters long, suitable for large-scale continuous production, meeting the client’s high-volume requirements.

- Precise temperature control and automated operation: 48kW electric heating power, adjustable frying time, equipped with an intelligent control panel, ensuring that each batch of Scotch eggs is fried evenly, maintaining a crispy exterior and tender interior.

- High-standard materials and design: the entire machine is made of 304 stainless steel, corrosion-resistant and easy to clean. The side-tilting design and drainage outlet are located on the same side for easy maintenance and cleaning.

- Multi-functional compatibility: in addition to Scotch eggs, it is also suitable for frying various foods such as French fries, meatballs, and fried chicken nuggets.

- Easy mobility: equipped with casters, its position can be flexibly adjusted according to the production line layout.

Equipment parameters and process advantages

- Processed material: 80mm Scotch eggs, weighing approximately 190g

- Frying time: approximately 7 minutes

- Belt speed: 0.024 meters/minute, adjustable according to food characteristics

- Machine dimensions: 2500 x 1000 x 1700 mm

- Power supply: 400V 50Hz Three-phase power

The commercial automatic frying machine operates stably and distributes heat evenly, ensuring uniform color and reasonable oil content in fried foods, while significantly reducing manual labor intensity and the risk of uneven production.

Customer feedback and cooperation prospects

After confirming the equipment parameters and delivery plan, the customer expressed high approval of our customized solution, believing that the fryer will significantly improve the production efficiency and quality of their Scotch eggs and other fried foods.

The customer indicated that they will consider purchasing additional frying and cooling equipment in the future to complete their overall processing production line. We will continue to provide equipment installation guidance, operation training, and after-sales service to ensure the customer can quickly achieve increased production capacity.