The fried banana plantain chips production line is well designed for making crispy banana and plantain chips at plants. The complete banana chip processing line integrates the following functions, such as green banana plantain peeling, slicing, frying, cooling, sugar leaching, re-frying, deoiling, seasoning, and packaging. Both the semi-automatic banana chips lines and full-automatic fried plantain chips lines are available in our factory at good prices. The fried plantain chips processing plant’s capacity ranges from 50kg/h, 100kg/h, 150kg/h, 200kg/h, 300kg/h, 500kg/h, and 1000kg/h.

Classifications of Taizy banana plantain chips production lines

As a strong food machinery manufacturer and supplier, Taizy factory currently mainly provides small semi-automatic banana chip production lines (100kg/h to 500kg/h) and large fully automatic fried plantain chips production lines (200kg/h to 1000kg/h) to customers at home and abroad.

Equipment list of the semi-automatic banana chips production line

| No. | Equipment name |

| 1 | Green banana peeling machine |

| 2 | Banana slicer machine |

| 3 | Banana chips blanching machine |

| 4 | Banana chips dewater machine |

| 5 | Banana chips fryer machine |

| 6 | Fried banana chips deoiling machine |

| 7 | Fried banana chips seasoning machine |

| 8 | Fried banana chips vacuum packaging machine |

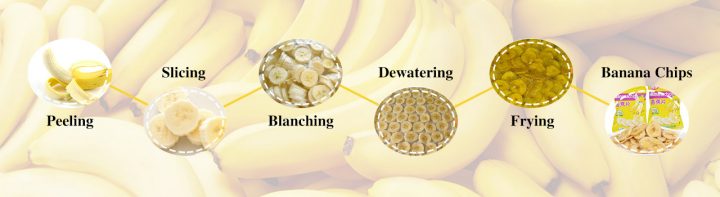

The production process of small fried banana chips processing line

The production process of the deep-fried banana chips processing line is simple and easy for the producer to operate. The production process mainly includes banana peeling, banana slicing, banana chips blanching, banana chips dewatering, chips frying, fried banana chips deoiling, fried banana chips seasoning, fried banana chips packaging, etc.

1.Banana peeler machine

Banana peeling machine is mainly used for batch peeling of bananas. The bananas used to make crisp banana chips are preferably fresh, non-damaging bananas with a maturity of 70 to 80%. Less ripe green bananas can also be used to make fried banana chips.

2. Banana slicer machine

This electric banana slicer machine is the commonly used slicing equipment for making all kinds of vegetable and fruit slices. It can make banana chips with a thickness of 5-8mm very quickly. After slicing, the producer can soake them in a sodium bisulfite solution with a concentration of 5-10% for 30-50 minutes for good tastes and colors.

3. Banana chips blanching machine

After slicing, these banana chips should be blanched with the electric blanching machine to remove the excess starch and debris. The banana chips are lightly blanched to ensure that they taste more delicious after frying.

4. Banana chips dewatering machine

Before frying these banana slices, we also need a fast dewatering machine to remove the water droplets of the banana chips. Therefore, when frying the banana chips, it will be more efficient and safe.

5. Banana chips fryer machine

Banana chips frying is the most important step of the semi-automatic banana chips production line. The heating methods of this fryer machine can be both electricity and liquified gas. Within 5-6 minutes frying with the temperature around 160 ℃, the crisp deep-fried banana chips will be finished.

6. Fried banana chips deoiling machine

After the deep-frying of the banana chips, the users should use an automatic deoiling machine for reducing the excess oil of the fried banana chips. So that can keep the good tastes of the banana chips.

7. Fried banana chips seasoning machine

By using this continuous seasoning machine, the banana chips producers can make their chips with different flavors. The banana chips seasoning machine has high efficiency of mixing the chips with seasonings fast and evenly.

8. Fried plantain chips packaging machine

The last step for processing banana chips is to pack these delicious chips into bags with the fully automatic intelligent packaging machine . It is often used in large potato chip production plants. Products packed with this automatic weighing and packaging machine not only have a very low breakage rate, but also pack quickly.

Machine list of large fried plantain chips processing plant

| No. | Equipment name |

| 1 | Green banana peeler |

| 2 | Banana slice cutter machine |

| 3 | Hoist conveyor 1 |

| 4 | Belt type banana chips blanching machine |

| 5 | Plantain chips air-drying and cooling machine |

| 6 | Hoist conveyor 2 |

| 7 | Leaching sugar machine |

| 8 | Hoist conveyor 3 |

| 9 | Belt type continuous frying machine |

| 10 | Fried banana chips deoiling machine |

| 11 | Hoist conveyor 4 |

| 12 | Fried plantain chips seasoning machine |

| 13 | Automatic banana chips packaging machine |

Full-automatic banana plantain chips production line’s features

- 1. A larger green banana peeler machine is needed for the automatic plantain chips line. This machine has different types and models as well as different capacities. It has two inlets with different diameters, which is suitable for peeling bananas of different sizes. And it needs at least 2 workers when working.

- 2. The electric hoist conveyors are required for the fried plantain chips production line. To achieve automatic production of banana chips, the conveyors will be very useful to reduce worker participation. And this banana chips line needs no less than 4 hoist conveyors for connecting each of the banana chip processing links.

- 3. Continuous plantain banana chips frying machine is the key equipment for full-automatic banana chip processing plant. The mesh belt fryer can work continuously, and the frying process does not require workers to participate, which can ensure the safety of the fried banana chip production process. The temperature of the plantain chips fryer can be set and adjusted between 100°C and 200°C. The oil residue formed after frying can be easily removed.

- 4. The main purpose of sugar dipping and seasoning in the production process of fried banana chips is to make fried plantain chips with a better taste. In actual production, customers can choose whether to dip banana chips with sugar and seasoning.

- 5. In order to meet the commercial production of crisp banana chips, we usually need to equip a large banana chip packaging machine. This continuous packaging machine can pack banana chip snacks into bags of various specifications. We can customize the weight of each bag of banana chips, the style and size of the packaging bag, etc. according to the packaging needs of customers.

Features of the fried plantain chips production line

- All the banana chips making machines in this line are made of high-quality 304 stainless steel, so that can make sure their long service life.

- For intelligent control of this complete production line, we can support the users with a PLC system, which can realize the easy and safe operation.

- If necessary, we can support the customer with the fried banana chips recipes for good selling on the market. And help do the profit analysis of the local banana chips production.

- The output of this fully automatic fried banana slice processing line is not unique but can be customized according to customer needs. The common output of customer orders is 150kg / h, 200kg / h, 300kg / h and 500kg / h.

- The complete set of machines are made of 304 stainless steel, which can not only ensure the flavor of the finished product but also ensure that the equipment has a long service life.

- In addition to providing customers with high-quality machines, we can also provide customers with the most reasonable production solutions and profit analysis for free to help customers get the maximum benefits from fried banana chips production.

Fried plantain banana chips production line video

How much does a plantain chips plant cost in Nigeria?

In Nigeria, including many African countries, the production of plantain chips by hand is very inefficient and unhygienic Commercial production of fried plantain chips there requires a automatic plantain chips production line. Therefore, many customers from Africa, especially Nigeria, will come to buy our banana chip processing plant every year.

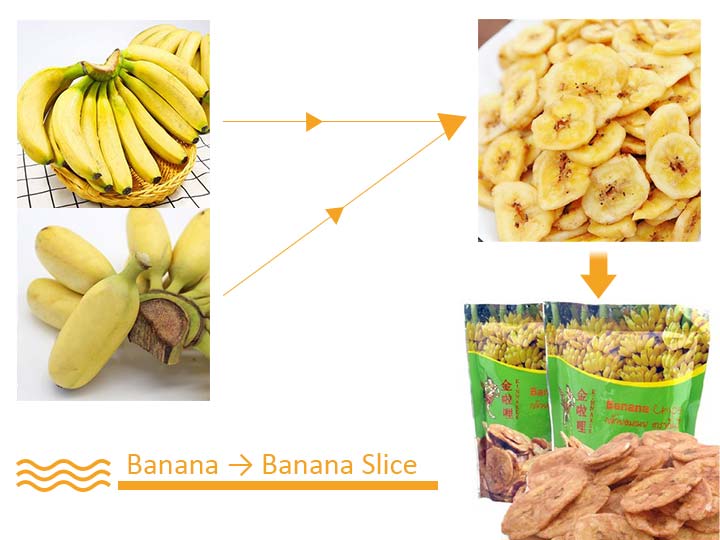

How to make commercial banana chips?

When you walk into the supermarket and see the savory banana chips on the shelf, you may can’t resist buying a packet to have a try, But have you ever wondered how does fried banana chips are produced? Can you really get a great return by investing in commercial banana chips?

Taizy machine is a banana chips production line machine manufacturer and supplier, If you want to invest in crisp deep-fried Plantain chips, or have any questions about automatic plantain chips production line, we will provide you with available solutions.

Prospect of Thailand fried banana chips business

Crisp deep-fried plantain chips are considered one of the most traditional products in the Thai snack market .With the development of economic globalization, many Thai farmers and investors are gradually starting to produce high-quality banana chips by importing banana chips machinery. Therefore, fried banana chips business is growing rapidly in many areas of Thailand.

As shown in the figure above, Thai banana chips are only 0.1cm thick. With the excellent ingredients, Thai fries taste crispy and fragrant like potato chips, which is why Thailand Fried Banana Chips have been popular all over the world.

The impact of the development of plantain chips processing on Zimbabwe

With the tremendous improvement of banana cultivation in Zimbabwe, the production of local banana has gradually increased. The continued popularity of banana chips processing business has increased the income of farmers,which has directly contributed to the economic development of many areas in Zimbabwe. Therefore, many local investors in Zimbabwe have invested in banana chips processing line to produce delicious fried banana chips.

How to make banana chips at home?

When we walk into the supermarket, we are sometimes attracted by the delicious packed banana chips. So can we make our own banana chips at home? The answer is of course you can. After you read this article, you can do a homemade banana chips in an oven, pot, pan or electric baking dish.

How to make more money on plantain chips business?

Starting a plantain chip business requires not only enough raw materials of plantain and workers, but also a complete plantain chip production line. Then, how to run a plantain chip factory to make more money?

- Ensure sufficient supply of plantains

- Have a complete production line of plantain chips

- Reduce the employment of workers

How to reduce the oil content of fried banana chips?

As we all know, sweet fried banana chips all have a certain oil content, whether they are made at home or produced by commercial banana chip processing plants. Eating foods with high oil content regularly will not only slow our brain, but also induce a variety of diseases.

The main steps to reduce the oil content of fried banana chips:

- Reduce the thickness of banana slices.

- Selecting the appropriate speed of centrifuge.

The Philippines encourages banana chips processing and exporting

The Philippines is the world’s largest exporter of banana chips. After years of development, the Philippine banana chips processing industry has formed a diversified production situation. With the development of economy, the increasing demand for casual snacks in the international market, coupled with the continuous updating of banana chips processing machinery, has made the Philippines pay more attention to the development of banana chips industry.

Nutritional value of fried banana/plantain chips

Bananas are a very nutritious fruit and one of the most popular fruits. with commercial crisp making machine,we can make Fresh bananas into crisp deep-fried banana chips through peeling, slicing, washing, frying, and seasoning. The Fried banana chips is one of the most popular snacks and is very easy to store.Then,Will the nutritional value of banana chips be lost after deep-frying?